| Height: Ground to Cab** |

8.5 ft

2592 mm

|

| Height: Ground to Beacon** |

9.08 ft

2774 mm

|

| Height: Ground Axle Center** |

1.58 ft

480 mm

|

| Height: Ground Clearance** |

1 ft

300 mm

|

| Length: Overall* |

17.58 ft

5366 mm

|

| Length: Rear Axle to Bumper |

4.58 ft

1391 mm

|

| Length: Hitch to Front Axle |

3.58 ft

1085 mm

|

| Length: Wheel Base |

7.08 ft

2170 mm

|

| Length: Front Axle to Front of Coupler |

3.5 ft

1065 mm

|

| Clearance: Bucket at 45° * |

8.25 ft

2505 mm

|

| Clearance: Load over Height** |

9.5 ft

2902 mm

|

| Clearance: Level Bucket** |

9.92 ft

3037 mm

|

| Height: Bucket Pin** |

10.67 ft

3251 mm

|

| Height: Overall** |

13.5 ft

4122 mm

|

| Reach: Bucket at 45° * |

2.33 ft

714 mm

|

| Carry Height: Bucket Pin |

1.08 ft

324 mm

|

| Dig Depth** |

0.33 in

113 mm

|

| Width: Bucket |

6.75 ft

2045 mm

|

| Width: Tread Center |

4.67 ft

1420 mm

|

| Turning Radius: Over Bucket |

14.75 ft

4489 mm

|

| Width: Over Tires |

6.07 ft

1848 mm

|

| Turning Radius: Outside of Tires |

12.92 ft

3925 mm

|

| Turning Radius: Inside of Tires |

6.75 ft

2057 mm

|

| Rack Angle at Full Lift |

56°

56°

|

| Dump Angle at Full Lift |

45°

45°

|

| Rack Angle at Carry |

51°

51°

|

| Departure Angle - Degrees |

30°

30°

|

| Articulation Angle - Degrees |

39°

39°

|

| Operating Weight: Bucket ^ |

12689 lb

5756 kg

|

| Tipping Load - Straight - ISO 14397-1 † |

9773 lb

4433 kg

|

| Tipping Load - Full Turn - ISO 14397-1 † |

8235 lb

3735 kg

|

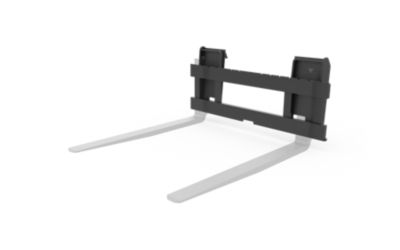

| Operating Weight: Carriage and Tines ^^ |

12220 lb

5543 kg

|

| Tipping Load - Straight † |

7807 lb

3541 kg

|

| Tipping Load - Full Turn † |

6569 lb

2980 kg

|

| 80% of Tip: Firm and Level EN474-3 †† |

5255 lb

2384 kg

|

| Note (1) |

*Vary with bucket

*Vary with bucket

|

| Note (2) |

**Vary with tire

**Vary with tire

|

| Note (3) |

^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL),1.05 m3 (1.4 yd3) general purpose bucket.

^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL),1.05 m3 (1.4 yd3) general purpose bucket.

|

| Note (4) |

^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

|

| Note (5) |

†Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

†Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

|

| Note (6) |

††Full compliance to EN474-3 and SAE J1197.

††Full compliance to EN474-3 and SAE J1197.

|

| Note (7) |

#HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

#HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

|

| Note (8) |

Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9 405/70 R18 tires and 1.05 m3 (1.4 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines, (tire supplier variability can impact dimensions by 2%).

Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9 405/70 R18 tires and 1.05 m3 (1.4 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines, (tire supplier variability can impact dimensions by 2%).

|

| Note (9) |

Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.

Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.

|

1140 mm (45 in), Single Tine

1140 mm (45 in), Single Tine

890 mm (35 in), Single Tine

890 mm (35 in), Single Tine

890 mm (35 in), Dual Tine

890 mm (35 in), Dual Tine

1140 mm (45 in), Dual Tine

1140 mm (45 in), Dual Tine

2.44 m (8 ft)

2.44 m (8 ft)

3.05 m (10 ft)

3.05 m (10 ft)

3.05 m (10 ft)

3.05 m (10 ft)

3.66 m (12 ft)

3.66 m (12 ft)

2.44 m (8 ft)

2.44 m (8 ft)

3.66 m (12 ft)

3.66 m (12 ft)

2.44 m (8 ft)

2.44 m (8 ft)

3.66 m (12 ft)

3.66 m (12 ft)

3.05 m (10 ft)

3.05 m (10 ft)

1.8 m (6 ft), Skid Steer Coupler

1.8 m (6 ft), Skid Steer Coupler

2.1 m (7 ft), Skid Steer Coupler

2.1 m (7 ft), Skid Steer Coupler

2.7 m (9 ft), Skid Steer Coupler

2.7 m (9 ft), Skid Steer Coupler

2.4 m (8 ft), Skid Steer Coupler

2.4 m (8 ft), Skid Steer Coupler

3.0 m (10 ft), Skid Steer Coupler

3.0 m (10 ft), Skid Steer Coupler

1803 mm (71 in)

1803 mm (71 in)

2133 mm (84 in)

2133 mm (84 in)

MB200

MB200

MB250

MB250

1300 mm (51 in), Skid Steer Coupler, Class II

1300 mm (51 in), Skid Steer Coupler, Class II

BRX118 Industrial

BRX118 Industrial

A23, Skid Steer Coupler

A23, Skid Steer Coupler

A41, Skid Steer Coupler

A41, Skid Steer Coupler

LT114

LT114

LT118

LT118

LR116

LR116

LR119

LR119

T315 Hydraulic Side Shift, Standard Chain

T315 Hydraulic Side Shift, Standard Chain

T315 Hydraulic Side Shift, Standard Chain

T315 Hydraulic Side Shift, Standard Chain

T109 Manual Side Shift, Standard Chain

T109 Manual Side Shift, Standard Chain

T112 Manual Side Shift, Combo Chain

T112 Manual Side Shift, Combo Chain

T112 Manual Side Shift, Standard Chain

T112 Manual Side Shift, Standard Chain

T112 Manual Side Shift, Rock-Frost Chain

T112 Manual Side Shift, Rock-Frost Chain

T112 Hydraulic Side Shift, Standard Chain

T112 Hydraulic Side Shift, Standard Chain

T112 Hydraulic Side Shift, Rock-Frost Chain

T112 Hydraulic Side Shift, Rock-Frost Chain

T112 Hydraulic Side Shift, Combo Chain

T112 Hydraulic Side Shift, Combo Chain

T109 Hydraulic Side Shift, Standard Chain

T109 Hydraulic Side Shift, Standard Chain

T109 Manual Side Shift, Standard Chain

T109 Manual Side Shift, Standard Chain

T109 Hydraulic Side Shift, Terminator Chain

T109 Hydraulic Side Shift, Terminator Chain

T109 Manual Side Shift, Combo Chain

T109 Manual Side Shift, Combo Chain

T109 Manual Side Shift, Terminator Chain

T109 Manual Side Shift, Terminator Chain

T109 Hydraulic Side Shift, Combo Chain

T109 Hydraulic Side Shift, Combo Chain

T109 Hydraulic Side Shift, Rock-Frost Chain

T109 Hydraulic Side Shift, Rock-Frost Chain

T109 Manual Side Shift, Rock-Frost Chain

T109 Manual Side Shift, Rock-Frost Chain

T109 Hydraulic Side Shift, Standard Chain

T109 Hydraulic Side Shift, Standard Chain

T112 Hydraulic Side Shift, Standard Chain

T112 Hydraulic Side Shift, Standard Chain

T315 Hydraulic Side Shift, Combo Chain

T315 Hydraulic Side Shift, Combo Chain

PC104

PC104

PC105

PC105

PC305

PC305

PC306

PC306

PC310

PC310

CV117

CV117

CV119

CV119

0.8 m3 (1.0 yd3), Skid Steer Coupler, Bolt-On Cutting Edge

0.8 m3 (1.0 yd3), Skid Steer Coupler, Bolt-On Cutting Edge

0.8 m3 (1.0 yd3), Skid Steer Coupler, Bolt-On Teeth

0.8 m3 (1.0 yd3), Skid Steer Coupler, Bolt-On Teeth

0.8 m3 (1.0 yd3), HPL-V Coupler, Bolt-On Cutting Edge

0.8 m3 (1.0 yd3), HPL-V Coupler, Bolt-On Cutting Edge

2007 mm (79 in)

2007 mm (79 in)

2337 mm (92 in)

2337 mm (92 in)

2080 mm (82 in), Skid Steer Coupler, Bolt-On Cutting Edge

2080 mm (82 in), Skid Steer Coupler, Bolt-On Cutting Edge

BA118C Manual, Polypropylene/Wire

BA118C Manual, Polypropylene/Wire

1524 mm (60 in)

1524 mm (60 in)

2134 mm (84 in)

2134 mm (84 in)

Material Handling Arm, Skid Steer Coupler

Material Handling Arm, Skid Steer Coupler

SG16

SG16

1829 mm (72 in)

1829 mm (72 in)

2134 mm (84 in)

2134 mm (84 in)

SR321

SR321

SR121

SR121

SR118

SR118

SR318

SR318

SW360, 80 mm (3 in)

SW360, 80 mm (3 in)

SW360, 160 mm (6 in)

SW360, 160 mm (6 in)

SW360, 200 mm (8 in)

SW360, 200 mm (8 in)

SW345, 130 mm (5 in)

SW345, 130 mm (5 in)

SW360, 100 mm (4 in)

SW360, 100 mm (4 in)

SW360, 130 mm (5 in)

SW360, 130 mm (5 in)

SW345, 80 mm (3 in)

SW345, 80 mm (3 in)

BP115C

BP115C

BP118C

BP118C