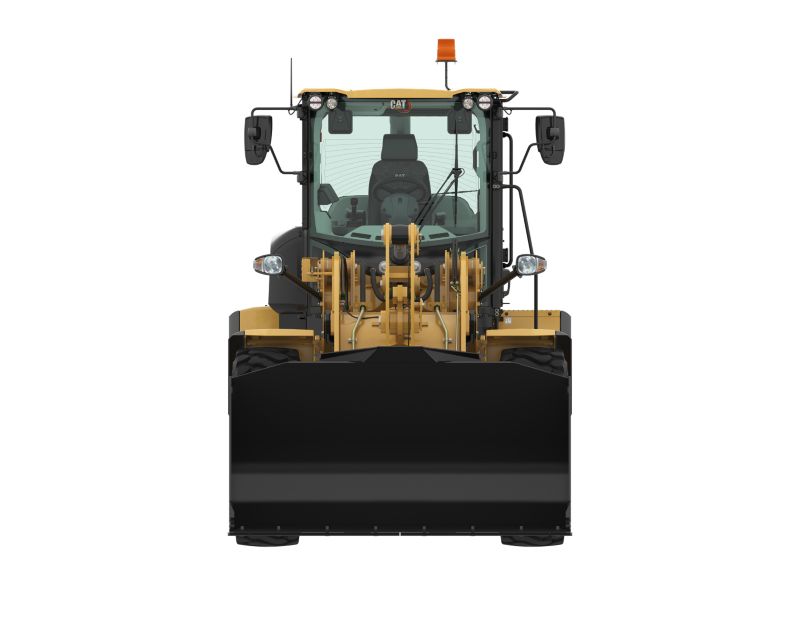

The Cat 930M Small Wheel Loader sets the standard for productivity, fuel efficiency and operator comfort. The improved optimized Z-bar loader linkage delivers the quick loading performance of a traditional Z-bar with the parallelism and load handling capability of a tool carrier. A high torque, low speed C7.1 ACERT engine works in concert with an intelligent hystat power train to deliver fuel efficiency as standard. Meets Tier 4 Final/Stage V emission standards with an environmentally friendly, Clean Emission Module designed to manage itself so you can concentrate on your work. Experience the new industry benchmark.

3.66 m (12 ft)

3.66 m (12 ft)

3.66 m (12 ft)

3.66 m (12 ft)

4.87 m (16 ft)

4.87 m (16 ft)

4.26 m (14 ft)

4.26 m (14 ft)

4.87 m (16 ft)

4.87 m (16 ft)

4.26 m (14 ft)

4.26 m (14 ft)

3.66 m (12 ft)

3.66 m (12 ft)

4.26 m (14 ft)

4.26 m (14 ft)

4.87 m (16 ft)

4.87 m (16 ft)

3.66 m (12 ft)

3.66 m (12 ft)

4.26 m (14 ft)

4.26 m (14 ft)

4.87 m (16 ft)

4.87 m (16 ft)

4.3 m (14 ft)

4.3 m (14 ft)

3.7 m (12 ft)

3.7 m (12 ft)

3.0 m (10 ft)

3.0 m (10 ft)

1566 mm (62 in)

1566 mm (62 in)

1566 mm (62 in)

1566 mm (62 in)

1566 mm (62 in)

1566 mm (62 in)

1524 mm (60 in)

1524 mm (60 in)

1829 mm (72 in)

1829 mm (72 in)

2.9 m3 (3.8 yd3), Fusion™ Coupler

2.9 m3 (3.8 yd3), Fusion™ Coupler

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.7 m3 (3.5 yd3), Fusion™ Coupler

2.7 m3 (3.5 yd3), Fusion™ Coupler

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.9 m3 (3.8 yd3), Fusion™ Coupler, BOCE

2.9 m3 (3.8 yd3), Fusion™ Coupler, BOCE

2.5 m3 (3.3 yd3), Fusion™ Coupler

2.5 m3 (3.3 yd3), Fusion™ Coupler

2.7 m3 (3.5 yd3), Fusion™ Coupler, BOCE

2.7 m3 (3.5 yd3), Fusion™ Coupler, BOCE

2.5 m3 (3.3 yd3), Fusion™ Coupler

2.5 m3 (3.3 yd3), Fusion™ Coupler

2.7 m3 (3.5 yd3), Fusion™ Coupler

2.7 m3 (3.5 yd3), Fusion™ Coupler

1524 mm (60 in)

1524 mm (60 in)

1829 mm (72 in)

1829 mm (72 in)

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.5 m3 (3.3 yd3), Fusion™ Coupler, BOCE

2.9 m3 (3.8 yd3), Fusion™ Coupler, BOCE

2.9 m3 (3.8 yd3), Fusion™ Coupler, BOCE

2.7 m3 (3.5 yd3), Fusion™ Coupler, BOCE

2.7 m3 (3.5 yd3), Fusion™ Coupler, BOCE

3.2 m3 (4.2 yd3), Fusion™ Coupler, BOCE

3.2 m3 (4.2 yd3), Fusion™ Coupler, BOCE

4.2 m3 (5.5 yd3), Fusion™ Coupler, BOCE

4.2 m3 (5.5 yd3), Fusion™ Coupler, BOCE

3.5 m3 (4.6 yd3), Fusion™ Coupler, BOCE

3.5 m3 (4.6 yd3), Fusion™ Coupler, BOCE

5.0 m3 (6.5 yd3), Fusion™ Coupler, BOCE

5.0 m3 (6.5 yd3), Fusion™ Coupler, BOCE

3.0 m3 (3.9 yd3), Fusion™ Coupler, BOCE

3.0 m3 (3.9 yd3), Fusion™ Coupler, BOCE

3.8 m3 (5.0 yd3), Fusion™ Coupler, BOCE

3.8 m3 (5.0 yd3), Fusion™ Coupler, BOCE

3.8 m3 (5.0 yd3), Pin On, Bolt-On Cutting Edge

3.8 m3 (5.0 yd3), Pin On, Bolt-On Cutting Edge

3.5 m3 (4.6 yd3), Fusion™ Coupler, BOCE

3.5 m3 (4.6 yd3), Fusion™ Coupler, BOCE

4.1 m3 (5.4 yd3), Fusion™ Coupler, BOCE

4.1 m3 (5.4 yd3), Fusion™ Coupler, BOCE

5.0 m3 (6.5 yd3), Fusion™ Coupler, BOCE

5.0 m3 (6.5 yd3), Fusion™ Coupler, BOCE