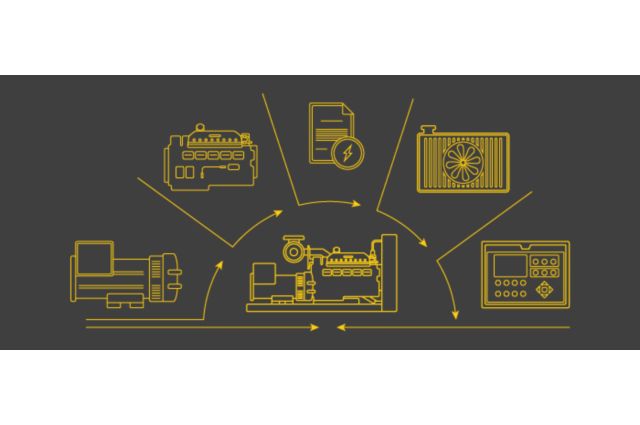

Producing reliable power from 36 to 60 ekW at 60 Hz, our C4.4 diesel generator sets designed to ISO 8528-5 transient response requirements. All C4.4 generator sets meet EPA Stationary Emergency (Tier 3) emissions standards.

Cat

C4.4 Generator Set

Overview

Photos

360° View

Exterior

Enclosure

Documents

- Electric Power Ratings Guide

- 60 Hz 40 ekW, EPA Tier III Compliant Emissions Spec Sheet

- 60 Hz 60 ekW, EPA Tier III Compliant Emissions Spec Sheet

- 60 Hz 50 ekW, EPA Tier III Compliant Emissions Spec Sheet

- 60 Hz 36 ekW, SCAQMD & US EPA Tier 3 equivalent Compliant Emissions Spec Sheet

- 60 Hz 40 ekW, SCAQMD & US EPA Tier 3 equivalent Compliant Emissions Spec Sheet

- 60 Hz 45 ekW, SCAQMD & US EPA Tier 3 equivalent Compliant Emissions Spec Sheet

- 60 Hz 50 ekW, SCAQMD & US EPA Tier 3 equivalent Compliant Emissions Spec Sheet

- 60 Hz 60 ekW, U.S. EPA Certified for Stationary Emergency Application Compliant Emissions Spec Sheet

- 60 Hz 55 ekW, U.S. EPA Certified for Stationary Emergency Application Compliant Emissions Spec Sheet

- C4.4 Diesel Generator Set, 60 Hz, 40 - 60 ekW, Spec Sheet

- GCCP 1.2 Control Panel Data Sheet

- 24-220 KVA SA LVL 2 Enclosure

- GCCP 1.5 Control Panel Data Sheet

Features

Specifications

-

Generator Set Specifications

Spec Value Maximum Rating 60 ekW Minimum Rating 36 ekW Emissions/Fuel Strategy U.S. EPA Cert., Tier 3 Voltage 208 to 600 Volts Frequency 60 Hz Speed 1800 rpm Duty Cycle Standby, Prime -

Engine Specifications

Spec Value Engine Model C4.4, In-line 4, 4-cycle diesel Bore 4.13 in Stroke 5 in Displacement 268.5 in Compression Ratio 18.2:1 Aspiration Turbocharged Fuel System Electronic (adjustable) Governor Type Adem™A4 -

Generator Set Dimensions

Spec Value Length - Maximum 75.8 in Width - Maximum 44.1 in Height - Maximum 53.6 in

Standard Equipment

Certificates

- IBC seismic and wind Certifications

Charging System

- NFPA battery charger UL10A 120VAC

Air Inlet System

- Air cleaner

- Cartridge type air filter

Circuit breakers

- Second circuit breaker box

- 3-Pole 100% rated

- Power terminal strip

- Breakers (100% UL rated)

Control Panel

- 1000028996

Exhaust System

- Stub pipe, gaskets, raincap and SAE exhaust flange for customer use - shipped loose

Fuel System

- Standard open set fuel tank/base supplied base, formed steel with single wall integral 8-hour fuel tank

Cooling System

- Coolant drain line with valve

- Radiator and cooling fan with guards

- Fan drive, battery charging alternator drive

- Caterpillar extended life coolant

- Radiator stone guard

Generator

- 12 Leads

Governing System

- Mechanical and electrical governing system - model dependent

Lube System

- Oil drain line with valve

- Lubricating oil

Control Panels

- WCA1 Low coolant temperature alarm

- WSS1 Low coolant level shut down

- FSS Low fuel level alarm & indication panel circuitry required when sub-base tank is selected

- NFPA110 bundle includes:

- PAA1 Panel mounted audible alarm

- A Coolant heater, remote annunciator or 0.8 power factor test may be required depending on the application

- Oil temperature gauge and sender

- PBC10NU NFPA battery charger

- Ground fault relay

- Discrete I/O module

- Volt free contacts genset run and common alarm

- Audible alarm

- Remote E-stop button

- Remote annunciator module

- Low coolant temperature alarm

- Protective devices:

- Overload shutdown via breaker

- Fuel level reading

- Low coolant level shutdown

General

- Engine and alternator pre-paint, Caterpillar yellow

Starting/Charging System

- 24V battery with rack and cables

- Batteries

Optional Equipment

Certificates

- IBC seismic and wind Certifications

Alternator System

- R Frame auxilliary winding

Air Inlet System

- Cartridge type air filter

Charging System

- NFPA battery charger UL10A 120VAC

Circuit breakers

- 3-Pole 100% rated

- Breakers (100% UL rated)

- Second circuit breaker box

- Power terminal strip

Control Panels

- Discrete I/O module

- Remote annunciator module

- Remote E-stop button

- Protective devices: Low coolant temperature alarm - Low coolant level shutdown - Fuel level reading - Overload shutdown via breaker

- Ground fault relay

- Audible alarm

- Oil temperature gauge and sender

- Volt free contacts genset run and common alarm

- NFPA110 bundle includes: FSS Low fuel level alarm & indication panel circuitry required when sub-base tank is selected - WSS1 Low coolant level shut down - WCA1 Low coolant temperature alarm - PAA1 Panel mounted audible alarm - PBC10NU NFPA battery charger - A Coolant heater ,remote annunciator or 0.8 power factor test may be required depending on the application

Heating Elements

- Coolant heater

- Battery heater

- Anti-condensation heater

- Lube oil sump heater

- Jacket water heater

- Wiring for canopy space heater

Cooling System

- Radiator transition flange

Enclosures

- Panel viewing window

- External emergency stop

- Sound attenuated enclosure, Level 2

- Weatherproof enclosure

- Sound attenuated enclosure, Level 1

Fuel System

- 5 Gallon fill containment

- Tank riser

- 209 and 394 gallon sub-base fuel tanks

- Emergency vent pipe

- 5 Gallon spill containment

Mounting System

- Seismic vibration isolators

Tests

- Generator test report

- PGS Test report @ 0.8 power factor

- 4 Hour factory test

- PGS Test report @ 1.0 power factor

Exhaust System

- 10, 25 and 35 dBA silencer systems

- Overhead silencer mounting kit

Generators

- Permanent magnet excitation (PMG) generator

Sign up for Ziegler CAT emails

Events, updates, and offers

30-220 kVA SA Lvl 1 Enclosure

30-220 kVA SA Lvl 1 Enclosure