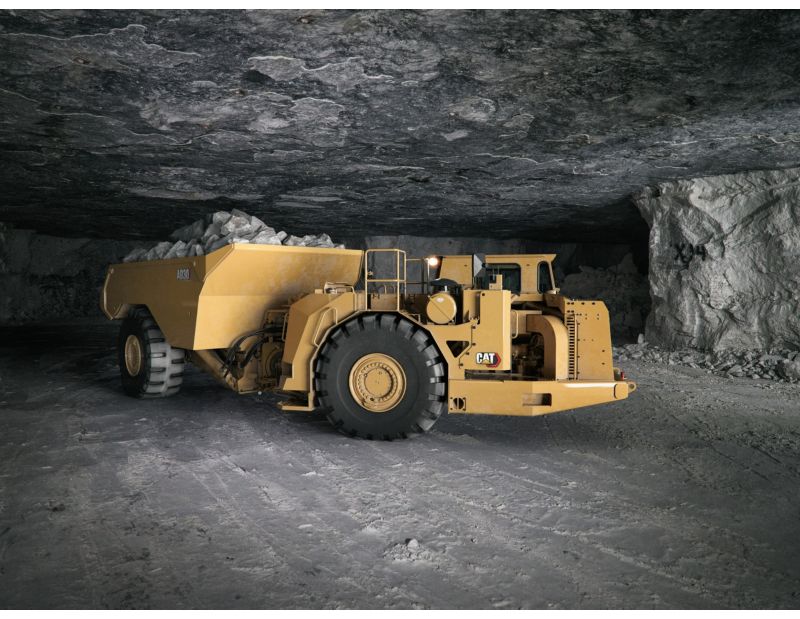

The Cat® AD30 Underground Truck is a medium to smaller mine hauler that is a perfect match to the Cat R1600H underground loader. Engineered for performance, it’s powered by the Cat C15 engine and delivers fast cycle times and maximum efficiency. With two body styles plus multiple body sizes, you can choose the right body to maximize efficiency in your application. The cab is ergonomically designed to keep operators safe, comfortable and in control. Rugged construction and easy maintenance guarantee long life with low operating costs.

Caterpillar

AD30 Underground Mining Truck

Overview

Photos

Videos

360° View

Exterior

360° Exterior view. Double click on the image to zoom in on any area of the product.

Interior

360° interior view. Double click on the image to zoom in on any area of the product.

Showroom

AD30 Product Tour

Features

Specifications

-

Engine

Spec Value Engine Model Cat® C15 Engine Power - Tier 3 Engine - ISO 14396:2002 401 hp Engine Power - VR Engine - ISO 14396:2002 401 hp Bore 5.4 in Stroke 6.8 in Displacement 928 in³ Note (1) Power ratings apply at a rated speed of 1,800 rpm when tested under the reference conditions for the specified standard. Note (2) All rating conditions are based on ISO/TR14396:2002, inlet air standard conditions with a total barometric pressure of 100 kPa (29.5 in Hg), with a vapor pressure of 1 kPa (0.295 in Hg), and 25° C (77° F). Performance measured using fuel to EPA specifications in 40 CFR Part 1065 and EU specifications in Directive 97/68/EC with a density of 0.845-0.850 kg/L @ 15° C (7.05-7.09 lb/gal @ 59° F) and fuel inlet temperature 40° C (104° F). Note (3) Engine derate will commence at an altitude of 2743 m (8,999 ft). Note (4) Optional Ventilation Reduction package available.

Optional engine with emissions equivalent to Tier 3 and EU Stage IIIA is also available.Note (5) Optional engine with emissions equivalent to U.S. EPA Tier 3 and EU stage IIIA is also available. -

Operating Specifications

Spec Value Nominal Payload Capacity 66139 lb Gross Machine Mass 132300 lb Body Capacities 11.3-17.5 m³ (14.8-22.9 yd³) -

Weights

Spec Value Empty 63647 lb Empty - Front Axle 42944 lb Empty - Rear Axle 20704 lb Loaded 132277 lb Loaded - Front Axle 58451 lb Loaded - Rear Axle 73826 lb -

Weight Distribution

Spec Value Empty - Front Axle 67.50% Empty - Rear Axle 32.50% Loaded - Front Axle 44.20% Loaded - Rear Axle 55.80% -

Transmission

Spec Value Forward - 1 3.9 mile/h Forward - 2 7 mile/h Forward - 3 12.9 mile/h Forward - 4 22.8 mile/h Reverse - 1 4.4 mile/h Note Maximum travel speeds with standard 26.5 × R25 tires. -

Final Drives

Spec Value Differential Ratio 3.38:1 Final Drive Ratio 4.76:1 Total Reduction Ratio 16.13:1 Note Fully floating axles. -

Body Hoist

Spec Value Raise 10.5 s Lower 11.2 s Total Cycle Time 21.7 s -

Body Capacities

Spec Value Body 1 14.8 yd³ Body 2 - Standard Body 18.8 yd³ Body 3 22.9 yd³ Wide Body 21.9 yd³ Ejector Body (1) 19.9 yd³ Ejector Body (2) 21.9 yd³ Note Heaped SAE 2:1. -

Turning Dimensions

Spec Value Outside Clearance Radius 337.4 in Inner Clearance Radius 198 in Articulation Angle 42.5 ° Frame Oscillation 10 Degrees -

Service Refill Capacities

Spec Value Engine Crankcase - With Filter 9 gal (US) Transmission 18 gal (US) Hydraulic Tank 38 gal (US) Cooling System 20 gal (US) Front Differential and Final Drives 15 gal (US) Rear Differential and Final Drives 15 gal (US) Fuel Tank 108 gal (US) -

Tires

Spec Value Tire Size 26.5 × R25 -

Standards

Spec Value Standards ROPS/FOPS Certified Cab

Standard Equipment

TIRES, RIMS, AND WHEELS

- Tires must be selected from the Mandatory Attachments section. Choose from below:

– Tire, 26.5 × 25 VSNT Bridgestone

– Tire, 26.5 × 25 VSDL Bridgestone - Rims (set of four) – five pieces, tubeless

ELECTRICAL

- 12V power supply in cab

- Alarm, reversing

- Alternator, 95 amp

- Battery disconnect switch, ground level

- Circuit breaker, 80-amp

- Corrosive protection spray

- Diagnostic connector

- Disconnect switch, two post, ground level

- Lights:

– Headlights with dimmer switch

– Brake and tail lights

– Reversing lights, automatic when reverse gear selected

– Work light, rear, cab mounted - Low maintenance batteries

- Receptacle group, auxiliary start

- Shutdown switch, ground level

- Starting and charging system

OPERATOR ENVIRONMENT

- Cab, ROPS/FOPS certified

- Open operator station ROPS/FOPS structure

- Caterpillar Electronic Monitoring System (CEMS), dash instrument panels

- Operator Presence System

- Automatic Brake Application (ABA)

- Electric horns

- Gauges:

– Engine coolant temperature

– Transmission coolant temperature

– Hydraulic oil temperature

– Fuel level

– Speedometer

– Tachometer - Indicator lights:

– Alert warning light

– Body up position warning

– High beam

– Residual brake pressure warning

– Retarder application

– Turn signal - Low hydraulic level warning

- Mirrors, rear view

- Seat, suspension operator seat with retractable seat belt

- Seat, trainer/passenger with seat belt

- Steering wheel, tilt/telescopic

POWER TRAIN

- Axle, arrangement:

– Standard width, front – rear - Brake retarder control, automatic

- Brakes:

– All wheel disc

– Oil cooled

– Multiple-disc (SAFR™) - Control throttle shifting

- Electric fuel priming pump

- Engine:

– Cat C15 six cylinder diesel engine

– Air-to-air aftercooler (ATAAC) - Exhaust, turbo compartment shielding

- Four wheel drive

- Gear blockout with tray up, programmable

- Ground speed limiting, programmable

- Long life coolant

- Parking brakes, four wheels

- Precleaner, engine air intake

- Radiator, cross flow; Radiator cap manual release

- Secondary steering system

- Transmission, automatic planetary power shift (4F/1R)

- Torque converter with automatic lockup

OTHER STANDARD EQUIPMENT

- Adapters, oil sample

- Alarm, tray up

- Body dump and ejector:

– Dump, (14.4 m3/18.8 yd3) - Cap, radiator, manual release

- Catalytic exhaust purifier/muffler group

- Centralized lubrication points

- Fenders:

– Front, rear flaps - Firewall

- Fuel system manual shut off tap

- Front rubber bumpers

- Handholds (access on/off top deck)

- Handrails

- Hitch, articulated and oscillated

- Lifting lugs, frame

- Lubrication system:

– Centralized, dump body - Operation and Maintenance Manual – English and other applicable local languages to select

- Scheduled Oil Sampling (S·O·SSM) port:

– Coolant

– Engine oil

– Hydraulic oil

– Transmission oil - Spill guard, front, for body

- Swing out radiator grill

- Tow pin, front and rear

Optional Equipment

POWER TRAIN

- Axle, arrangement:

– Wide body, front – rear - Brake pressure gauges

- Engine options:

– Engine, Ventilation Reduction (VR)

– Equivalent to Tier 3 - After treatment options (for use with VR engine only) Diesel Particulate Filter (DPF) (flow through) filter

- Fast Fill System:

– Coolant

– Engine oil

– Fuel (dual tanks)

– Hydraulic oil

– Transmission oil - Park Brake Switch Engagement – Push to Apply/Pull to Apply

ELECTRICAL

- Battery shutdown:

– Ground Level Isolation, In Cab Isolation Switch

– Ground Level Isolation, Engine Shutdown Switch

– Ground Level Isolation, In Cab Isolation, Engine Shutdown Switch - Lights:

– Headlights with dimmer switch, LED

– Reversing lights, automatic when reverse gear selected, LED

– Work light, rear, cab mounted, LED

OPERATOR ENVIRONMENT

- Operator’s station ROPS/FOPS enclosed:

– Air conditioning

– Cab pressurizer and filter

– Dome light

– Heater

– Radio ready compartment for radio and speakers

– Sun visor

– Window, sliding cab door - Seat:

– Suspension seat Cat Comfort TLV2, vinyl

– Suspension seat tee, mechanical - Seat cover:

– Tee and Cat Comfort TLV2

– Seat cover, companion

TECHNOLOGY

- Vital Information Management System (VIMS) Gen 3

- Payload:

– Truck Payload Measurement System (TPMS)

TIRES, RIMS, AND WHEELS

- Rim identification numbering

- Spare rim, tubeless

OTHER OPTIONAL EQUIPMENT

- Body dump and ejector:

– Dump, (11.3 m3/14.8 yd3)

– Dump, (16.8 m3/21.9 yd3) (wide body configuration)

– Dump, (17.5 m3/22.9 yd3)

– Ejector, (15.2 m3/19.9 yd3)

– Ejector, (16.8 m3/21.9 yd3) - Body liners, impact and/or wear

- Camera – color rear facing

- Cover, anti vandalism for shipping

- Fenders:

– Wide body, front, rear flaps - Fire suppression system:

– Foam, water based - Fluids:

– Arctic fuel

– Arctic coolant - Lubrication system:

– Automatic, dump or ejector body

– Centralized, ejector body - Mine transfer

- Reflective tapes

- Service tools

Sign up for Ziegler CAT emails

Events, updates, and offers