For your largest power needs in any environment, Cat?� 3512 Industrial Diesel Engines offer the unsurpassed performance and durability your customers need to keep their industrial applications and operations running. They deliver high power output, proven reliability and excellent fuel efficiency. These engines maintain low operating costs to keep your customers profitable for years to come. Industries and applications powered by 3512 engines include Bore/Drill Rigs, Chippers/Grinders, Construction, Cranes, Dredgers, Forestry, General Industrial, Material Handling, Mining, Mobile Earthmoving Equipment, Pumps, Shovels/Draglines, Surface Hauling Equipment and Trenchers. These 3512 engines, with ratings: 761-1119 bkW (1020-1500 bhp) @ 1200-1800 rpm, are non-certified. They are available for global non-regulated areas.

Caterpillar

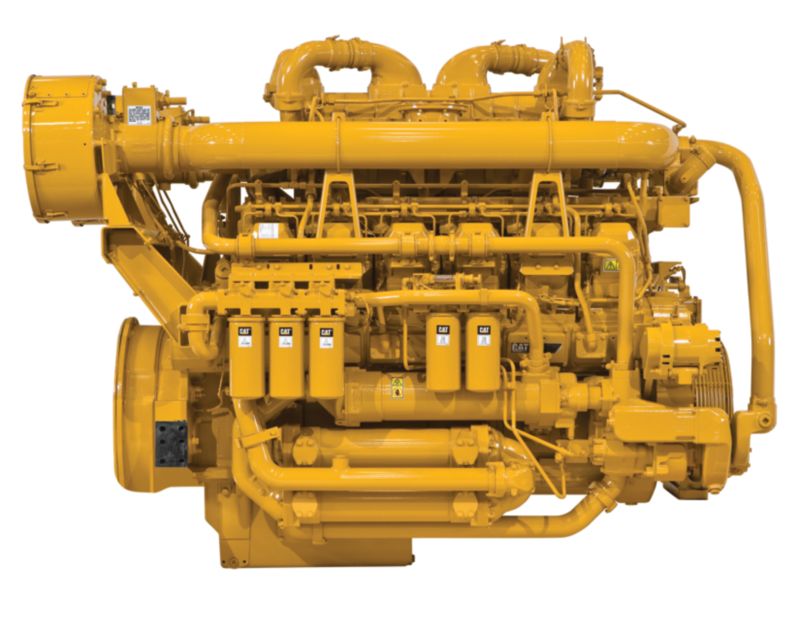

Cat?� 3512 Industrial Diesel Engine

Photos

Features

Specifications

-

Power Rating

Spec Value Maximum Power 1500 hp Maximum Torque 4580 lb-ft @ 1400 rpm Rated Speed 1200-1800 rpm Minimum Power 1020 hp -

Emission Standards

Spec Value Emissions Non-Certified -

General

Spec Value Engine Configuration V-12, 4-Stroke-Cycle Diesel Bore 6.7 in Stroke 7.5 in Displacement 3161 in³ Compression Ratio 13.0:1 Aspiration Turbocharged Aftercooled Rotation from Flywheel End Counterclockwise Aftertreatment - -

Engine Dimensions - Approximate

Spec Value Length 105 in Width 67 in Height 68 in Weight - Net Dry - Basic Operating Engine Without Optional Attachments 13400 lb

Standard Equipment

Air Inlet System

- Aftercooler core, corrosion resistant coated (air side)

- Air cleaner. Regular duty, dry, panel type with service indicators, turbocharger, jacket water aftercooled.

- Turbocharger, rear mounted

- Jacket water aftercooled

Control System

- Governor, RH, 3161 with self contained synthetic oil sump

- Air-fuel ratio control

- Mechanical speed control, without torque control

- Governor control

- Positive locking

Cooling System

- Thermostats and housing

- Jacket water pump, centrifugal

Exhaust System

- Exhaust manifold, dry

Flywheels and Flywheel Housing

- SAE No. 00 flywheel

- 183 flywheel teeth

- SAE No. 00 flywheel housing

Fuel System

- Fuel filter, with service indicators, cartridge type with RH service

- Fuel transfer pump

Instrumentation

- Instrument Panel, RH

- Engine oil pressure gauge

- Fuel pressure gauge

- Oil filter differential gauge

- Jacket water temperature gauge

- Service meter, electric

- Tachometer

Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filler

- Oil dipstick

- Oil pump

- Oil filter, cartridge type with RH service

- Shallow oil pan

- Fumes disposal (not installed)

Mounting System

- Rails, mounting, engine length, 254 mm (10 in), industrial-type, C-channel.

Power Take Off

- Accessory drive, upper RH

- Front housing, single sided

Protection System

- Junction box

- Manual shutoff, RH

- Safety shutoff protection, energized to shutdown

- Low oil pressure, low idle 69 kPa (10 psi); high idle 207 kPa (30 psi)

- Water temperature

- Overspeed

- 3161 governor solenoid energized to shutdown

Starting System

- Starting switch

General

- Vibration damper

- Lifting eyes

- Paint: Caterpillar yellow, with optional colors available at request

Sign up for Ziegler CAT emails

Events, updates, and offers