The Cat® D9 Dozer is a versatile machine designed to be used in a variety of applications, such as ripping overburden, production dozing, stockpiling, winching, site maintenance, fleet support and reclamation. It can be equipped with a number of blade options to meet site-specific needs. A highly reliable and fully integrated Cat machine, the D9’s components work together to ensure top performance, high availability and long life. Features like the new stator clutch torque converter boost efficiency and reduce fuel usage, and a number of onboard technology solutions further increase efficiency and performance. These improvements — and more — make the D9 a dozer that delivers a lower overall cost per unit of material moved.

Cat

D9 Dozer

Overview

Photos

Videos

360° View

Exterior

360° Exterior view. Double click on the image to zoom in on any area of the product.

Interior

360° interior view. Double click on the image to zoom in on any area of the product.

Showroom

Features

Specifications

-

Engine - U.S. EPA Tier 2/3 Equivalent

Spec Value Engine Model Cat® C18 Engine Power - Net SAE J1349/ISO 9249 452 hp Bore 5.7 in³ Stroke 7.2 in Displacement 1106 in³ Engine Power - Gross SAE J1995 487 hp Engine Power - ISO 14396 479 hp Emissions U.S. EPA Tier 2 or Tier 3 equivalent Note (1) All engine ratings apply at 1,750 rpm. Note (2) No derating required up to 4267 m (14,000 ft) altitude. -

Engine - U.S. EPA Tier 4 Final/EU Stage V

Spec Value Engine Model Cat® C18 Bore 5.7 in³ Stroke 7.2 in³ Displacement 1106 in³ Engine Power - Gross SAE J1995 477 hp Engine Power - ISO 14396 468 hp Engine Power - Net SAE J1349/ISO 9249 440 hp Emissions U.S. EPA Tier 4 / EU Stage V Note (1) All Engine ratings apply at 1,750 rpm. Note (2) No derating required up to 2499 m (8,200 ft). -

FLUID CAPACITIES

Spec Value Fuel Tank (Splash Fill) 254 gal (US) DEF Tank (Tier 4 only) 9.5 gal (US) Fuel Tank (Fast Fill) 248 gal (US) Cooling System 21 gal (US) Engine Crankcase* 10 gal (US) Powertrain 40 gal (US) Final Drives (each) 4 gal (US) Roller Frames (each) 12 gal (US) Pivot Shaft Oil 8 gal (US) Hydraulic System Tank 24 gal (US) Note *With oil filters. Note 2 Biodiesel blends up to B20 (20% blend by volume) are acceptable when blended with 15 ppm (mg/kg) sulfur or less ULSD. B20 should meet ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel spec, ASTM D6751 or EN 14214). Cat DEO-ULSTM or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specification are required. Consult your OMM for further machine specific fuel recommendations. Note 3 All non-road Tier 4 Final diesel engines are required to use only ultra-low sulfur diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less. Note 4 Diesel Exhaust Fluid (DEF) used in Cat Selective Catalytic Reduction (SCR) systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241. -

Weights

Spec Value Operating Weight 110225 lb Shipping Weight 84373 lb Note (1) D9 Operation Weight includes hydraulic controls, blade tilt cylinder, coolant, lubricants, full fuel tank, ROPS, FOPS cab, SU Blade, Single-Shank Ripper, 610 mm (24 in) ES shoes and operator. Note (2) D9 Operation Weight includes base machine chassis with cab, pivot shaft, roller frames, track and ROPS. -

Hydraulic Controls

Spec Value Pump Type Piston-type geared to flywheel Pump Output - Steering 96 gal/min Fan Pump 21 gal/min Tilt Cylinder Flow - Rod End Flow 53 gal/min Tilt Cylinder Flow - Head End Flow 53 gal/min Lift Cylinder Relief Valve Setting 3800 lbf/in Tilt Cylinder Relief Valve Setting 2799 psi Ripper - Lift - Relief Valve Setting 3800 psi Ripper - Pitch - Relief Valve Setting 3800 psi Steering System - Pressure 5874 psi Tank Capacity 24 gal/min Note (1) Steering pump output measured at 1,750 engine rpm and 30 000 kPa (4,350 psi). Note (2) Implement pump output measured at 1,750 engine rpm and 20 000 kPa (2,900 psi). Note (3) Fan pump output measured at 1,750 engine rpm and 17 000 kPa (2,470 psi) -

Undercarriage

Spec Value Shoe Type Extreme Service Width - Shoe 24 in Shoes/Side 43 Grouser Height 3.3 in Pitch 9.4 in Ground Clearance 18.1 in Track Gauge 88.6 in Length - Track on Ground 136.6 in Ground Contact Area 45.6 ft² Track Rollers/Side 8 Number of Carrier Rollers 1 per side (optional) -

Steering and Brakes

Spec Value Steering Type Differential Brake Type Spring Applied Wet Disc Brake Diameter 15.5 in Brake Count 8 -

Air Conditioning System

Spec Value Air Conditioning The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430) the system contains 2.1 kg of refrigerant which has a CO2 equivalent of 3.003 metric tonnes. -

Standards

Spec Value ROPS Rollover Protective Structure (ROPS) meets the following criteria ISO 3471:2008. FOPS Falling Object Protective Structure (FOPS) meets the following criteria ISO 3449:2005 LEVEL II. Sound The average dynamic spectator sound power level when ISO 6395:2008 is used to measure the value for a machine is 116 dB(A). The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. NOTE: The dynamic sound power level uncertainty is +/-2 dB(A). Sound (1) The average dynamic operator sound pressure level when ISO 6396:2008 is used to measure the value for an enclosed cab is 78 dB(A). The measurement was conducted at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds. The cab was properly installed and maintained. The measurement was conducted with the cab doors and the cab windows closed. NOTE: The dynamic operator sound pressure level uncertainty is +/-2 dB(A). Sound (2) Hearing protection may be needed when the machine is operated with an open operator station for extended periods, in a noisy environment, or with a cab that is not properly maintained. -

Transmission

Spec Value 1.0 Forward 2.2 mile/h 2.0 Forward 3.9 mile/h 3.0 Forward 6.8 mile/h 1.0 Reverse 2.7 mile/h 2.0 Reverse 4.8 mile/h 3.0 Reverse 8.4 mile/h Type Planetary powershift -

Blade - Semi-Universal

Spec Value Blade Capacity (SAE J1265) 17.8 yd³ Blade Width (over end bits) 171.3 in Blade Height 76.1 in Maximum Digging Depth 23.9 in Ground Clearance at Full Lift 56 in Maximum Tilt 37 in Blade Weight 10587 lb Total Operating Weight* (with blade and single-shank ripper) 110205 lb Note * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. -

Blade - Universal

Spec Value Blade Capacity (SAE J1265) 21.7 yd³ Blade Width (over end bits) 184.3 in Blade Height 76.1 in Maximum Digging Depth 23.9 in Ground Clearance at Full Lift 56 in Maximum Tilt 39.9 in Blade Weight 12016 lb Total Operating Weight* (with blade and single-shank ripper) 111362 lb Note *Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. -

Ripper - Single Shank

Spec Value Maximum penetration force * (shank vertical) 35520 lbf Maximum penetration depth (standard tip) 48.5 in Pryout Force 74637 lbf Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole 34.7 in Number of Pockets 1 Weight 10701 lb Total Operating Weight* (with SU Blade and noted ripper) 110205 lb Note *Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. -

Ripper - Single Shank, Deep Ripping

Spec Value Maximum penetration force * (shank vertical) 38667 lbf Maximum penetration depth (standard tip) 68 in Pryout Force 74412 lbf Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole 32.2 in Number of Pockets 1 Weight 10981 lb Total Operating Weight* (with SU Blade and noted ripper) 110485 lb Note *Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. -

Ripper - Multi-Shank, Adjustable Parallelogram

Spec Value Maximum Penetration Force - Shank Vertical 34621 lbf Maximum Penetration - Standard Tip 31.4 in Pry-Out Force - Multi-Shank Ripper with One Tooth 81156 lbf Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole 34.6 in Number of Pockets 3 Weight 12136 lb Total Operating Weight* - With SU-Blade and Ripper 111739 lb Note * Total Operating Weight includes: single tilt hydraulics, coolant, lubricants, full fuel tank, ROPS, FOPS cab, 610 mm (24 in) ES track shoes and the noted blade and ripper type. -

Winches

Spec Value Winch Model PA 140VS Weight* 3950 lb Oil Capacity 4 gal (US) Drum Width 12.6 in Wire Cable Diameter - Recommended 1.13 in Wire Cable Diameter - Optional 1.25 ft Maximum Drum Capacity - Recommended Cable Length 257 in Maximum Drum Capacity - Optional Cable Length 204 ft Wire Cable Ferrule Size - Outside Diameter 2.4 in Wire Cable Ferrule Size - Length 2.8 in Note *Weight shown is base winch only. Does not include mounting arrangement, control arrangement, oil, or wire rope. With counterweight: 3700 kg (8,150 lb). Note (2) Variable speed, hydraulically driven, dual braking system, three-roller fairlead. -

Dimensions (Approximate)

Spec Value Ground Clearance* 18.1 in Track Gauge 88.6 in Width - Without Trunnions - Standard Shoe 113 in Width - Over Trunnions 130.3 in Height - FOPS Cab* 150.4 in Height - Top of Stack* 152.6 in Height - ROPS/Canopy* 157.5 in Drawbar Height (Center of Clevis)* 30 in Length - Track on Ground 136.6 in Overall Length - Basic Tractor 193.3 in Length - Basic Tractor - With Drawbar 206.4 in Length - Basic Tractor - With Winch 218.3 in Length - With SU-Blade** 259.9 in Length - With U-Blade 274.3 in Length - With Single-Shank Ripper 257 in Length - With Multi-Shank Ripper 257.4 in Overall Length - SU-Blade/SS Ripper 323.6 in Note (1) *Includes grouser height for total dimensions on hard surfaces.

Standard Equipment

OPERATOR ENVIRONMENT

- ROPS/FOPS, Sound-Suppressed Cab

- High-Definition Primary Touchscreen Display

- Visibility – Rearview Mirrors

- Air Conditioner and Heater with Automatic Climate Control

- Seatbelt, 76 mm (3 in) Retractable with Switch

- Seat — Cloth with Air Suspension

- Window Wipers with Wash — Low, High, Intermittent

- Differential Steering — Power Turn

- Entertainment Radio Ready (12V Power, Harness, Speakers)

- Cab Glass — Single-Pane Tinted Safety

- Cab Door — Right-Hand Swing

- Access/Egress Lighting with Shutdown Timer

- "Operator Not Present" Detection

- Armrest — Adjustable

- Interior LED Courtesy Lights

- Interior Backlighting — Dimmable

- Air Conditioning Condenser — Cab Mounted (Standard only on Tier 4 engine arrangements. Optional on Tier 2/3 versions. Tier 2/3 versions have underhood A/C condenser standard.)

- Decelerator Pedal

- Controls — Blade — Electronic

- Controls — Ripper — Electronic

- Park Brake — Electronic

- Engine Speed Control Dial

- Cab Access — Blade Pusharm Steps and Grab Handle

- Fender Platform Guardrails

- Site Communication Radio Mount

- Four Fluids (Engine Oil, Coolant, Power Train, Fuel)

- Continuous Fluid Level Monitoring — Four Fluids (Engine Oil, Power Train, Coolant, Fuel)

- Slope and Side Slope Monitor

TECHNOLOGY

- VIMS™

- Automated Blade Assist (ABA) — When Equipped with Dual Tilt

- Cat Product Link Elite (Cellular) (Where Allowed by Local Regulations)

POWER TRAIN

- Aftercooler, air-to-air

- Air filter, with precleaner

- Aluminum bar plate radiator, 6 fpi

- C18 Tier 4 Final and Stage IV: – 24-volt electric start – Clean Emissions Module

- Coolant, extended life

- Shift management: - Advanced Productivity Electronic Control System (APECS) - Enhanced AutoShift (EAS)

- Engine idle shutdown timer

- Ether starting aid, automatic

- Fast fuel system

- Fuel priming pump, key-on, electric

- High speed oil change system, engine and power train

- Muffler

- Parking brake, electronic

- Prescreener

- Separator, water/fuel

- Three planet, double-reduction planetary final drives

- Torque converter

- Transmission, electronic control (ECPC), (3F/3R speeds)

FLUIDS

- Coolant — Extended Life, Standard (— 37° C / — 25° F)

UNDERCARRIAGE

- Suspension-Type Undercarriage

- Track Guide

- Two-Piece Master Link

- Lifetime-Lubricated Rollers and Idlers

- Hydraulic Track Adjusters

- Equalizer Bar — Greased End Pin Bearings

HYDRAULICS

- Electronically Controlled, Load-Sensing Dozer Lift and Tilt

- Electronically Controlled, Load-Sensing Ripper Lift and Pitch

- Electronically Enabled Blade, Quick Drop

ELECTRICAL

- Alternator — 150-Amp

- Batteries — 2 x 4, 200-Amp Hour, 12V

- 12V, 15-Amp Converter

- Battery Isolation

- Backup Alarm

- Lights, Engine Compartment

- Lights — Halogen — 8 Positions

SERVICE AND MAINTENANCE

- Ecology Fluid Drains — All Compartments

- Hinged Bottom Guards

- High-Speed Oil Change — Engine and Transmission

- S•O•S℠ Fluid Sampling Ports

- Diagnostic Connector

- CapSureTM Hammerless Ripper Tip and Shank Protectors

- Anchorage Points (10)

Optional Equipment

OPERATOR ENVIRONMENT

- Visibility – Camera – Ripper Tip View

- Visibility — Dual Camera

- Visibility — Four Cameras — 360-Degree View

- Seat — Heated, Cooled, Adjustable Lumbar and Bolsters

- Entertainment Radio — AM/FM, Aux Input and Bluetooth®

- Cab Glass — Dual-Pane Laminated Impact Safety

- Cab Glass — High-Pressure Safety (40 psi/275 kPa)

- Window Sunscreen

- Small Operator 5th Percentile Mounting Group

- Cab Door — Left-Hand Swing

- Cab Access — Powered Ladder

- Cab Filter Powered Precleaner

TECHNOLOGY

- AutoCarry™

- Auto Ripper Control

- Cat Product Link Elite Dual Mode (Cellular + Satellite)

- Cat GRADE with 3D

POWER TRAIN

- Coolant, arctic

- Engine prelube

- Exhaust, wrapped: – Insolated Clean Emissions Module

- Final drives: – Cold weather – Guarded – Waste handling

- Ground level DEF fill

- Reversible cooling fan

FLUIDS

- Coolant — Extended Life, Arctic (— 51° C / — 60° F)

- High Ambient Lubrication Package

- Arctic Lubrication Package

UNDERCARRIAGE

- Undercarriage Arrangement — Abrasion

- Undercarriage Arrangement — Waste Handling

- Undercarriage Arrangement — Cold Weather

- Front Striker Bars

- Rubber Idler Guards

- Track Links — Heavy Duty XL — DuraLink

- Track Shoe — Anti-Packing Round Hole Carrier Roller

- Carrier Roller

- Carrier Roller — Cold Weather

HYDRAULICS

- Dozer Blade Dual Tilt

- Ripper Pin Puller

- Guarded Tilt Cylinder Lines

ELECTRICAL

- 24V Electric Start, Dual Starters

- Batteries — 4 x 200, 200-Amp Hour, 12V

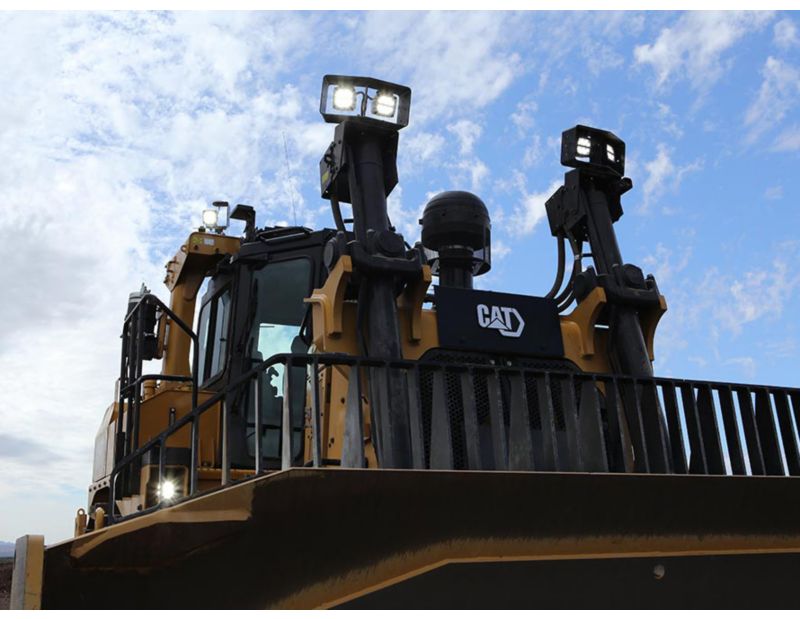

- Lights — Halogen — 12 Positions

- Lights — LED — 14 Positions

- Lights — High-Output LED — 14 Positions

- Light — Warning Strobe

SERVICE AND MAINTENANCE

- Sound-Reduction Sealed Bottom Guards

- Ground-Level Fast Fuel Fill (Standard on Tier 4)

- Sound Enclosure

- Cat Autolube Grease System with Ground-Level Fill and Auto Shutoff

- Hinged Quick-Access Door on Radiator Guard

REAR ATTACHMENTS

- Ripper Ready

- Winch Ready

- Ripper — Single Shank

- Ripper — Single-Shank Deep

- Ripper — Multi Shank (three shank)

- Counterweight

- Striker Box (Waste)

- Winch

- Drawbar

BLADES

- Semi-Universal (13.6 m3/17.8 yd3)

- Semi-Universal Abrasion (13.6 m3/17.8 yd3)

- Universal (16.6 m3/21.7 yd3)

- Universal Abrasion (16.6 m3/21.7 yd3)

- Semi-Universal Push Plate (13.6 m3/17.8 yd3)

- SU Landfill (28.2 m3/36.8 yd3)

- Universal Landfill (38.8 m3/50.8 yd3)

- Woodchip (46.1 m3/60.3 yd3)

- Coal (36.8 m3/48.2 yd3)

— Some blades only available through Cat Work Tools.

— SU Abrasion and U Abrasion are available with black paint on back side.

OTHER

- Fire Suppression Ready

SPECIAL ARRANGEMENTS

- High Debris

- Stockpile

- Waste Handling

- Sound

- Arctic

Sign up for Ziegler CAT emails

Events, updates, and offers