Caterpillar is leading the power generation marketplace with Power Solutions engineered to deliver unmatched flexibility, expandability, reliability, and cost-effectiveness.

Features

-

Cat Generator Set Package

- Cat generator set packages have been fully prototype tested

- Accepts 100% block load in one step and meets NFPA 110 loading requirements

- Conform to ISO 8528-5 steady state and transient response requirements

-

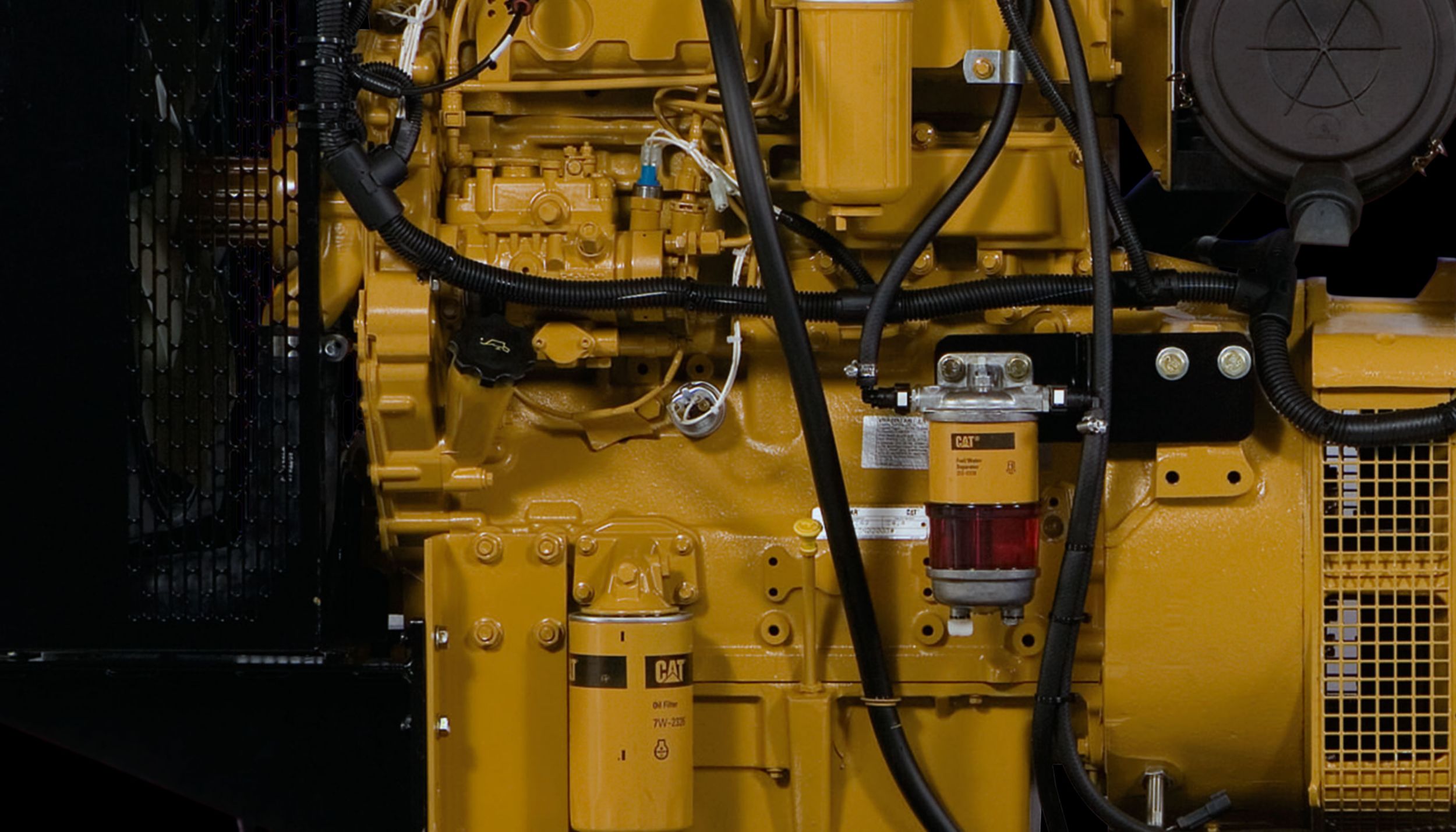

Cat Diesel Engine

- Reliable, rugged, durable design

- Field-proven in thousands of applications worldwide

- Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight

-

A-Frame Alternator

- Superior motor starting capability minimizes need for oversizing alternator

- Designed to match performance and output characteristics of Cat diesel engines

- Robust Class H insulation

-

GCCP 1.2 Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

-

Cooling System

- Designed to operate in standard ambient temperatures up to 55°C (131°F)

- Contact your Cat Dealer for specific ambient and altitude capabilities

-

Certifications

- UL2200 Listed; CSA 22.2; Certification of Compliance – IBC Seismic; Dual IBC & HCAI

-

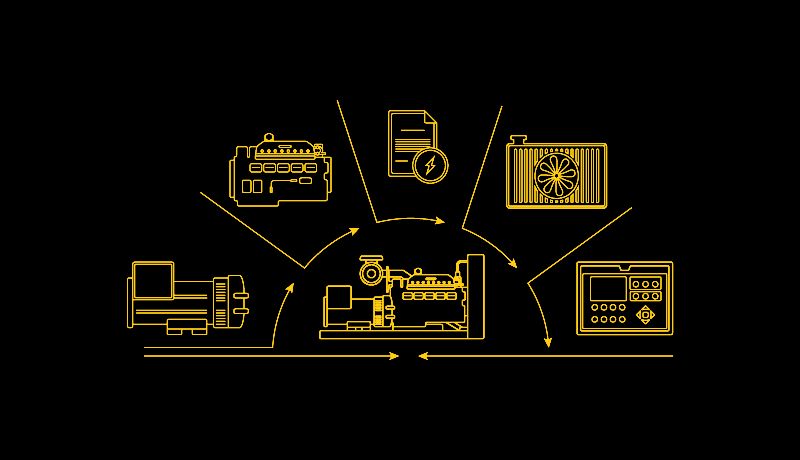

One Safe Source

- Components used in the generator set are selected based on seamless design integration to provide the optimum performance

- The generator set is fully assembled at a Caterpillar facility following our quality guidelines

- Each generator set package is tested before leaving the Caterpillar facility

- Cat product support, including dealer service, parts and warranty covers the entire Cat power system

-

World Wide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

-

Cat Clean Emissions Module (CEM)

- The Tier 4 Final engine has been optimized to work with the Cat CEM.

- The CEM is a reliable, compact, and lightweight system that gives maximum installation flexibility.

- It features a diesel oxidation catalyst for particulate matter (PM) and hydrocarbon (HC) control.

- Selective catalytic reduction (SCR) reduces NOx output and provides integrated sound attenuation.

- The CEM is controlled by a separate dosing module that has been integrated into the standard generator set controls for complete monitoring, protection and closed loop NOx control.

- For more information on the CEM, refer to cut sheet LEHE0359.

-

UL 2200 / CSA - Optional

- UL 2200 listed packages

- CSA Certified

- Certain restrictions may apply.

- Consult with your Cat® Dealer.

Specifications

Units for specifications

Generator Set Specifications

| Maximum Rating | 500 ekW |

|---|---|

| Minimum Rating | 455 ekW |

| Emissions/Fuel Strategy | U.S. EPA Tier 4 Final |

| Voltage | 480 Volts |

| Frequency | 60 Hz |

| Speed | 1800 rpm |

| Duty Cycle | Standby, Prime |

Engine Specifications

| Engine Model | C18 ATAAC, I-6, 4-Stroke Water-Cooled Diesel |

|---|---|

| Bore | 1455.7 in 145 mm |

| Stroke | 7.2 in 183 mm |

| Displacement | 1106.4 in³ 18.1 l |

| Compression Ratio | 14.5:1 |

| Aspiration | Air to Air Aftercooled |

| Fuel System | Electronic unit injection |

| Governor Type | Adem™A4 |

Standard Equipment

Air Inlet

- Air cleaner

Exhaust System

- Exhaust manifold - dry

Cooling

- Package mounted radiator

Fuel System

- Fuel cooler

- Engine fuel transfer pump

- Primary fuel filter w/integral water separator and secondary filter

- Fuel priming pump

- Flexible fuel lines

Exhaust

- Exhaust flange outlet

Fuel

- Primary fuel filter with integral water separator

- Fuel priming pump

- Secondary fuel filters

Generator

- Matched to the performance and output characteristics of Cat engines

- IP23 Protection

- Load adjustment module provides engine relief upon load impact and improves load acceptance and recovery time

Power Termination

- Busbar

Lube System

- Oil filter and dipstick

- Lubricating oil

- Oil drain lines with valve; piped to edge of base

- Fumes disposal, piped to front of radiator

- Oil cooler

Control Panel

- GCCP Genset Controller

Mounting

- Rubber vibration isolators

Protection System

- Safety shutoffs for: Higher water temperature - Overspeed - Low oil pressure

Cooling System

- Thermostats and housing, full open temperature 92 deg C (198 deg F)

- Coolant level sensor

- Coolant level sight gauge

- Fan and belt guards

- Jacket water pump, gear driven, centrifugal

- Coolant drain line with valve; terminated on edge of base

- Caterpillar extended life coolant

Starting/Charging

- 24V, 45 Amp Charging alternator

- 24 Volt electric starting motor

- 24 volt starting motor

- Batteries

General

- Paint - Caterpillar yellow except rails and radiators gloss black

- Paint, Caterpillar yellow

- Operation and maintenance manual pack and OMM storage compartment

- Parts book

- Vibration damper

Control System

- Local annunciator

- Programmable Input / Output: 2 programmable digital inputs - 2 programmable relay outputs (Form A) - 2 programmable relay outputs (Form C)

- Suitable for use as service equipment label

- Separation plate

- Control panel mounting location

- Breaker box mounting location

- Optional external analog input

- Remote annunciators

- GCCP 1.2

- Communications: Customer data link (RS485 Modbus RTu) - Serial annunciator module data link for local and remote annunciator IVR - Integrated Voltage Regulation (Digital) - EM10 Excitation Module

- Controls include: Run/auto/ stop/control - Speed adjust - Voltage adjust - Engine cycle crank - Emergency stop pushbutton

- Digital indication for: rpm - DC volts - operating hours - Oil pressure (psi, kPa or bar) - Coolant temperature (C or F) - Volts (L-L & L-N), frequency (Hz) - Amps (per phase & average) - Power factor (per phase & average) - kW (per phase & average) - kVA (per phase & average) - kVAr (per phase and average) - kW-hr (total) - kVAr-hr (total)

- Programmable protective relaying functions: Generator phase sequence - Over/under voltage (27/59) - Over/under frequency (81 o/u) - Overcurrent (50/51)

- Warning/shutdown with common LED indication of shutdowns for: Low oil pressure - high coolant temperature - Overspeed - Emergency stop - Failure to start (overcrank) - Low coolant temperature - Low coolant level

- Control panel options: Dust proof control panel - volt free contact - Device server - Ground fault relay

Governing System

- Cat electronic governor (ADEM A4)

Generator and Attachments

- Segregated low voltage (AC/DC) wiring panel

- Brushless, self-excited 2/3 pitch, random wound.

- Insulation Class H and temperature rise

- AREP generator

- CIP - generators

- IP23 Protection

- Power center, IP22 bottom cable entry

Air Inlet System

- Single element air filter

- Air cleaner - Heavy duty

- Air cleaner - Single element

Extended Service Coverage

- Silver, Gold and Platinum coverage

Circuit breakers

- 3 Pole 100% rated

Optional Equipment

Control System

- Ground fault relay

- Dust proof control panel

- Breaker box mounting location

- Volt free contact

- Device server

- Separation plate

- Remote annunciators

- GCCP 1.5

- Local annunciator

- Remote E-stop button

- Optional external analog input

- Control panel mounting

Exhaust

- Industrial, residential, critical mufflers

Generator

- Anti-condensation heater

- Excitation: [ ] Permanent magnet excitation (PMG) Excited (PM) [ ] Internally Excited (IE)

- Oversize and premium generators

Power Termination

- Circuit breakers, UL listed

Generators and Attachments

- AREP generator

- CIP generators

- Space heater

- Generator mounting and duct plate

Air Inlet System

- Single element air filter

- Dual element air cleaner

Certifications

- Certificate of Compliance

- IBC Certification wind load

Circuit breakers

- Motorized single circuit breaker

- Neutral bars

- Power cables

- Dual breakers first circuit breaker (CB2) LS/I package mounted

- Current transformers

- Package mounted single circuit breakers

- Dual breakers first circuit breaker (CB1) LS/I package mounted

- Auxiliary contacts

Cooling System

- Aftertreatment guard

- Standard radiator

Enclosures

- Sound attenuated enclosures

Exhaust System

- Flange kits

- Exhaust flexible fittings

Fuel System

- 660 gallon base tank

Generator Attachments

- Permanent magnet excitation (PMG) generator

Mounting System

- Standard base wide

- 5 Gallon spill containment

- Optional CB shroud

- Overfill prevention valve

- Locking fuel fill

Starting / Charging System

- Battery disconnect switch

- Jacket water heater

- Shore power control group

- 10 Amp dual Battery charger

TESTS

- PGS Test report @ 0.8 power factor

- 4 Hour factory test (un-witnessed)

- PGS Test report @ 1.0 power factor

- Generator test report

Documents

- Electric Power Rating Guide

- C18, 60 Hz, 500 ekW Standby, US EPA Tier 4 Final Nonroad Emission Standard Spec Sheet

- C18, 60 Hz, 455 ekW Prime, US EPA Tier 4 Final Nonroad Emission Standard Spec Sheet

- C18, 60 Hz, 500 ekW Standby, 455 ekW Prime, US EPA Tier 4 Final Non-Road Emission Spec Sheet

- GCCP 1.2 Control Panel Data Sheet

- GCCP 1.5 Control Panel Data Sheet