When it comes to heavy equipment, the smallest details can make the biggest difference. That’s why Ziegler’s SOS Services Fluid Lab exists: to help customers prevent costly breakdowns and keep machines running at their best.

Every day, the lab processes 700 to 1,000 samples of oil, coolant and diesel fuel from customers across Minnesota, Iowa, Missouri and beyond. The goal is speed and accuracy: Most samples are completed the same day, and most customers have results within 24 hours. That quick turnaround helps businesses make informed decisions before problems escalate.

Sending in a sample is a proactive step toward protecting your investment. Fluid analysis monitors equipment health, identifies contamination and detects early signs of wear. By catching issues before they become major failures, customers can schedule maintenance strategically and avoid unplanned downtime. The result is lower operating costs and longer equipment life.

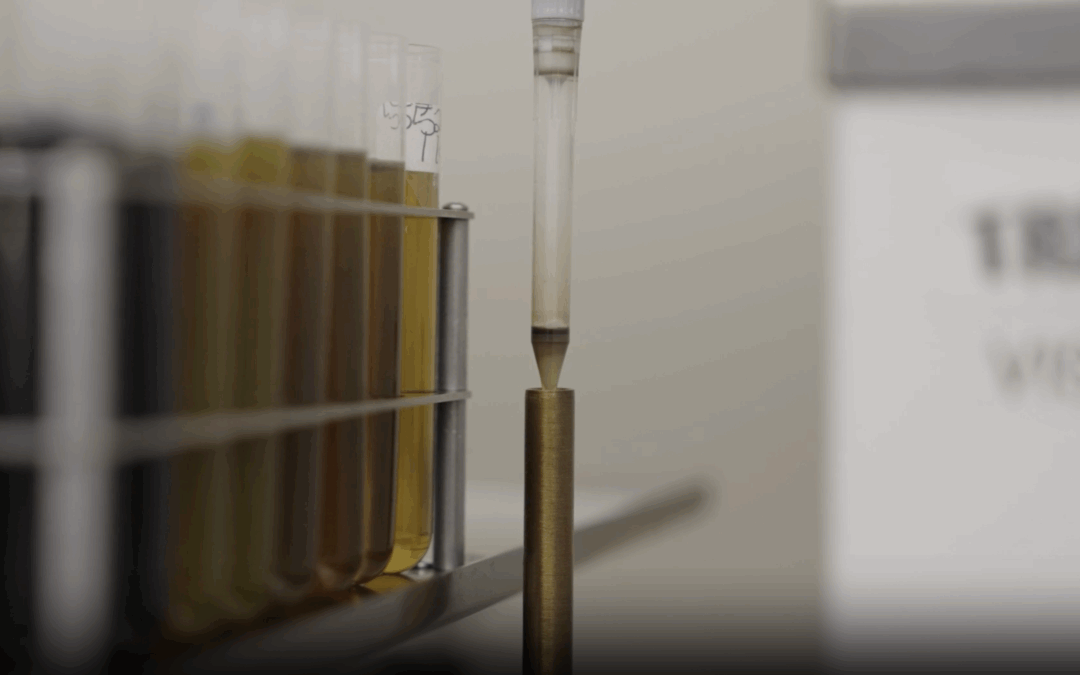

The process begins as soon as a sample arrives. It’s labeled, registered and assigned an ID before moving through a series of tests. Technicians shake and dilute the oil, then run it through advanced instruments. One standout tool, the ICP (inductively coupled plasma), operates at an incredible 5,000 to 6,000 degrees Celsius—about the temperature of the sun’s surface—to measure trace elements of metals like iron, copper and silicon. These readings help reveal whether internal components are wearing down.

The lab also analyzes filters and coolants. Filters are cut open and examined under a microscope to identify debris, which can indicate dirt ingress or component wear. Coolant samples are tested for corrosion and contamination, ensuring the entire system stays healthy.

Over the past two decades, the lab has evolved from manual testing to automated systems, improving accuracy and reducing repetitive strain for technicians. Customers can now preregister samples using QR codes and apps like Cat Inspect, speeding up data entry and eliminating paperwork. In a commitment to sustainability, the lab recycles solvents used in testing, cutting waste and saving costs.

Fluid analysis may seem small, but its impact is huge. By trending data over time, Ziegler helps customers prevent breakdowns, reduce costs and keep equipment running longer. It’s all part of our mission to maximize uptime and deliver value where it matters most.

Want to learn more or start sampling? Purchase kits here or contact your local Ziegler branch today and discover how proactive maintenance can pay off.