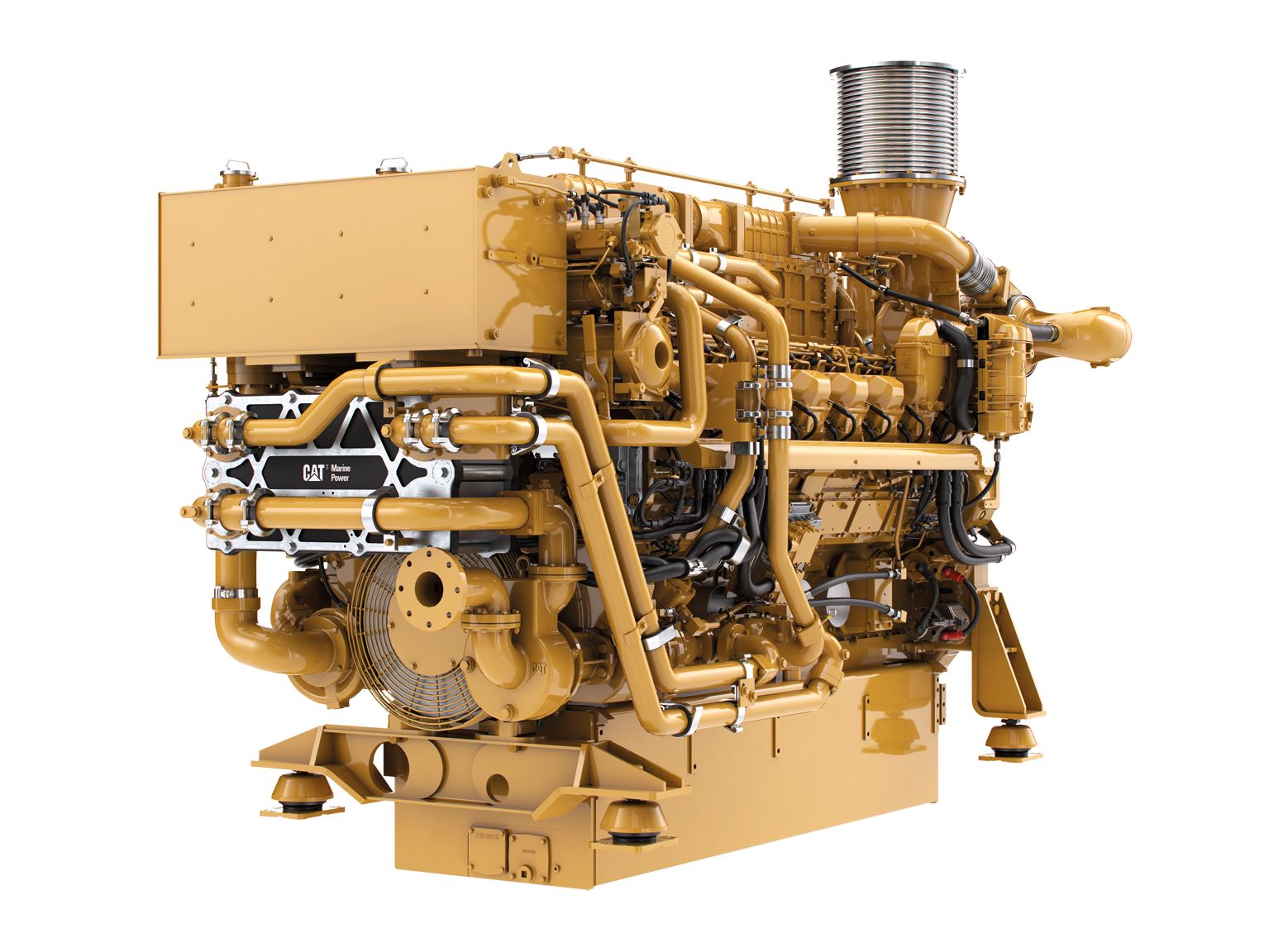

The 3516E marine auxiliary engine is now available in a wide range of ratings that meet U.S. EPA Tier 4 Final and IMO III marine emissions regulations. As the commercial marine industry adjusts their operations to meet EPA Tier 4 and IMO III emissions standards, Caterpillar Marine has introduced a solution built to maximize performance while meeting regulations. Caterpillar’s combination of a fuel-efficiency-optimized engine and a selective catalytic reduction (SCR) aftertreatment system is a solution that not only reduces NOx emissions, but can also lower a customer’s owning and operating costs in the process.

Features

-

Emissions

Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliant

-

Utilizes closed loop air assisted DEF dosing control strategy

Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea quality

-

Advanced Engine Combustion Design

Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiency

-

Enhanced control of fuel injection

Enhanced control of fuel injection optimized through crank timing and the latest A5 ECM technology

-

Enhanced Fuel Delivery

Optimal fuel injector nozzle geometry and electronic injection control for improved fuel delivery

-

Increased Durability and Higher Engine Duty Cycle Capability

Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capability

-

Caterpillar Warranty

Industry-leading warranty coverage for factory packaged components

-

Global Dealer Network

No matter where or when, our extensive global dealer network is ready to provide support

Specifications

Units for specifications

Power Rating

| Power Range | 1921 - 2368 bkW |

|---|

Generator Set Specifications

| Frequency | 50 / 60 |

|---|

Engine Specifications

| Emissions | U.S. EPA Tier 4, IMO II/III |

|---|---|

| Aspiration | Turbocharged - Aspirator |

| Bore | 6.69 in 170.0 mm |

| Stroke | 8.46 in 215.0 mm |

| Displacement | 4765.0 in³ 78.0 l |

| Configuration | V 16, 4-Stroke-Cycle Diesel |

| Rotation from Flywheel End | Counterclockwise |

Dimensions & Weights

| Minimum Width | 72.8 in 1850.0 mm |

|---|---|

| Dry Weight | 22060.0 lb 10006.0 kg |

| Height | 90.9 in 2309.0 mm |

| Maximum Width | 87.9 in 2230.0 mm |

| Length | 146.6 in 3724.0 mm |

Standard Equipment

Air Inlet System

- Corrosion-resistant aftercooler core

Control System

- Dual A5 engine control modules with electronic unit injection and low pressure fuel system

Cooling System

- Auxiliary fresh water pump

- Gear Driven, centrifugal jacket water pump with 40% more capacity

Exhaust System

- Dual turbochargers with water-cooled bearings and heat shields

Fuel System

- Duplex Fuel and Oil Filtration

General

- Vibration damper and guard

- Meets SOLAS regulations