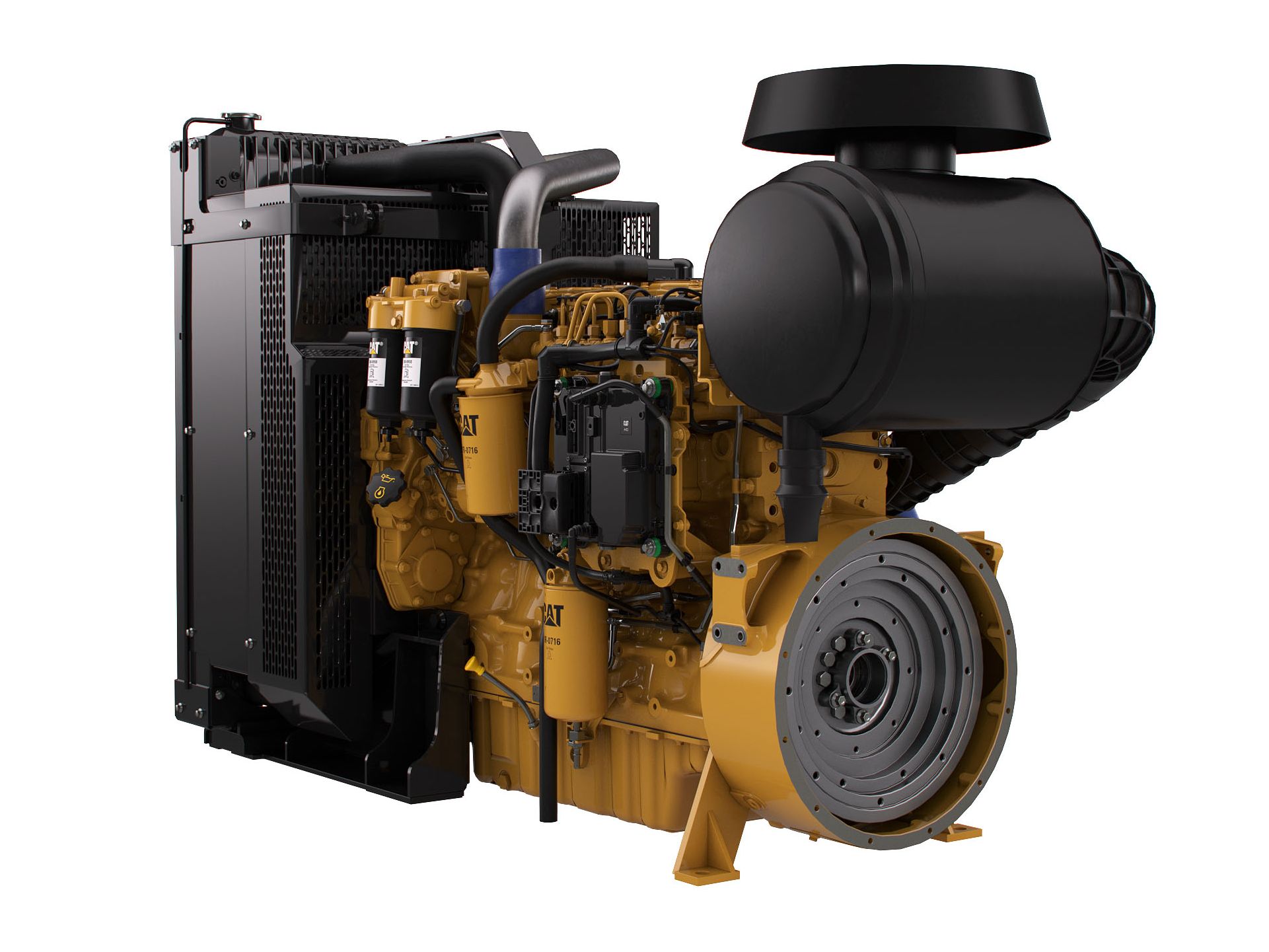

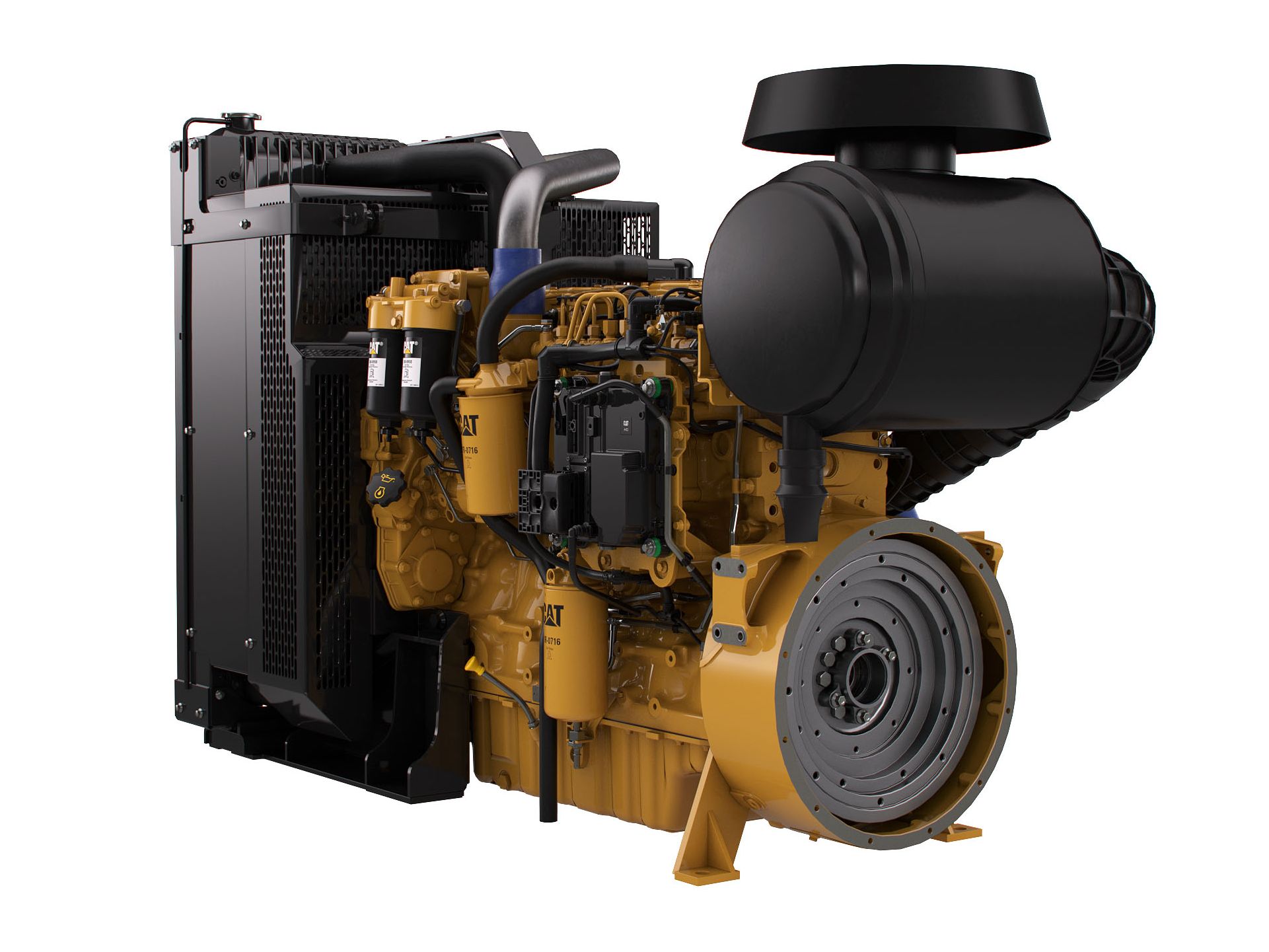

The C7.1 Industrial Power Unit is a complete power package containing a radiator, flywheel, alternator and alternator wiring, completely pre-assembled for fast, straightforward installation in a number of OEM, customer and packager applications. These fuel efficient units are ready-made for irrigation, industrial, mining and other pump applications.

Features

-

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

-

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

-

Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

-

Package Size

Exceptional power density enables standardization across numerous applications. Multiple installation options minimize total package size. Ideal for equipment with narrow engine compartments.

-

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOS℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Specifications

Units for specifications

Power Rating

| Maximum Power | 275 hp 205 kW |

|---|---|

| Maximum Torque | 774 lb-ft @ 1400 rpm 1050 Nm @ 1400 rpm |

| Rated Speed | 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm |

| Minimum Power | 156 hp 116 kW |

Emission Standards

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

|---|

General

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel |

|---|---|

| Bore | 4.1 in 105 mm |

| Stroke | 5.3 in 135 mm |

| Displacement | 427.7 in³ 7.01 l |

| Compression Ratio | 16.8:1 |

| Aspiration | Turbocharged Aftercooled (TA) |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | - |

Power Unit Dimensions

| Length | 68 in 1728 mm |

|---|---|

| Width | 31 in 788 mm |

| Height | 44.8 in 1140 mm |

| Weight | 1737 lb 788 kg |

Standard Equipment

Air Inlet

- Standard air cleaners

Control System

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

Cooling System

- Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

- 50:50 water glycol mix

- Cooling system designed for operation in 48 C (118 F) ambient.

Flywheels and Flywheel Housing

- Wide choice of drivetrain interfaces, including SAE No. 1, SAE No. 2, and SAE No. 3 configurations

Fuel System

- Electronic high pressure common rail

- ACERT Technology

- Innovative filter design to ensure maximum protection of the engine

Lube System

- Wide choice of sumps for different applications

Power Take Off

- SAE A or SAE B flanges on left-hand side. Right-hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications.

General

- Paint: Caterpillar yellow