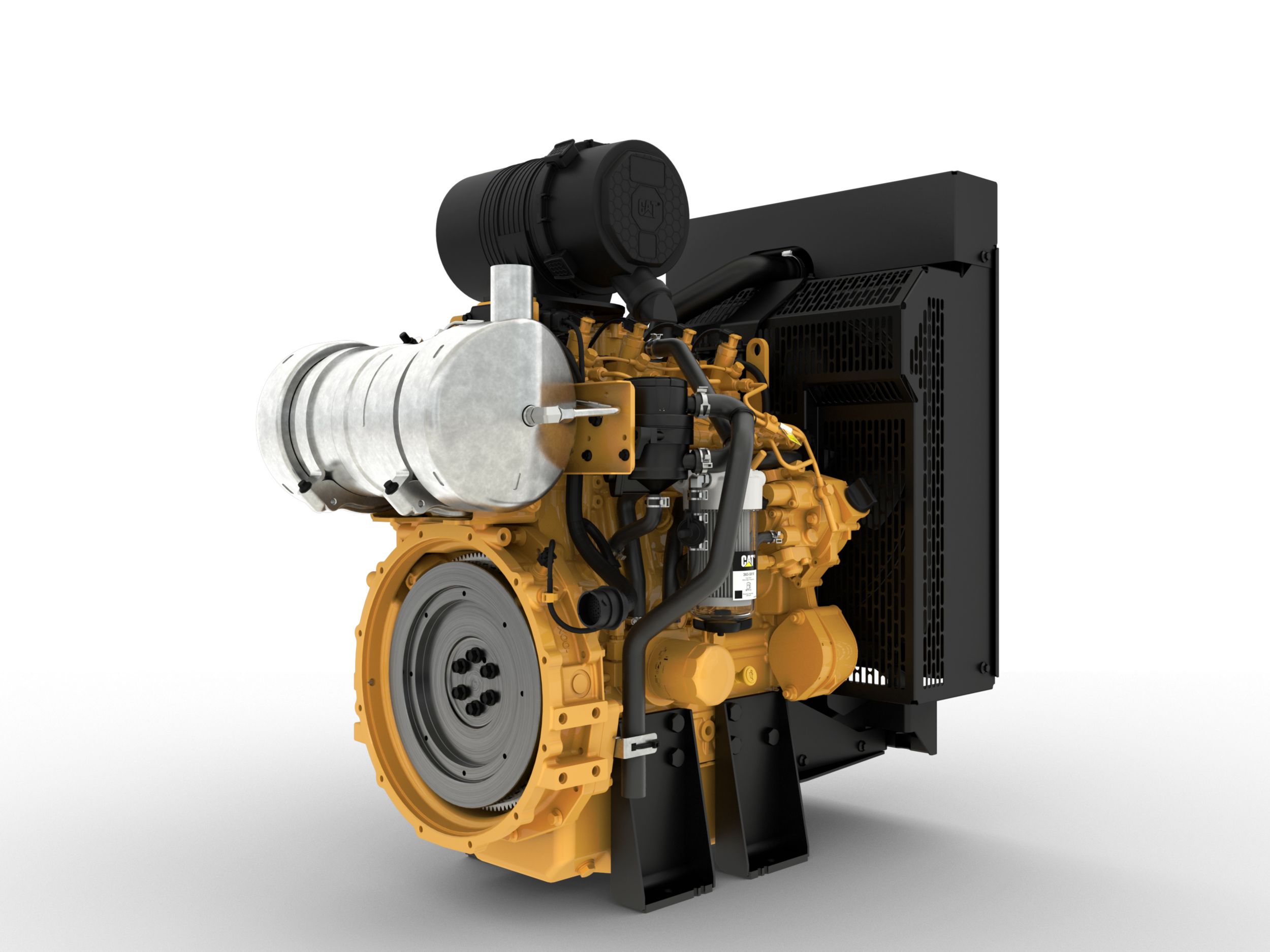

The Cat™ C2.2 IPU is available as a turbocharged or turbocharged aftercooled, common rail direct injection engine meeting EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 (Tier 4 Final) emission standards. For ease of installation, the IPU provides full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounted air filter.

Features

-

Easy integration for OEM’s

Fully integrated from the factory, with aftertreatment and air filter ready mounted to the IPU offering a wide range of options to suit your application in agriculture, material handling, construction, mining, aircraft ground support, and many other industries.

-

Reliable and Durable Power for Customers

World-class manufacturing capability and processes coupled with proven technologies, offer improved power density up 10 percent power and 30 percent improvement in peak torque over the previous generation turbocharged C2.2, allowing you to downsize, saving installation space on your products. And with our extensive field validation, our IPU’s save you engineering development time and costs.

-

Simple Service for Technicians

Worldwide dealer support from concept to completion and beyond, parts, training and service are never far. Combine that with easy maintenance, simplified servicing, 500 hour oil change interval, and factory fitted fit-for-life Diesel Particulate Filter with no downtime for regeneration and you’ve got a Cat® powered product ready to take on your toughest tasks.

Specifications

Units for specifications

Power Rating

| Maximum Power | 74 hp 55 kW |

|---|---|

| Maximum Torque | 199 lb-ft @ 1600 rpm 270 Nm @ 1600 rpm |

| Rated Speed | 2800 rpm |

| Minimum Power | 49 hp 36.4 kW |

Emission Standards

| Emissions | EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 (Tier 4 Final) |

|---|

General

| Engine Configuration | In-Line 4, 4-Stroke-Cycle Diesel |

|---|---|

| Bore | 3.3 in 84 mm |

| Stroke | 3.9 in 100 mm |

| Displacement | 135 in³ 2.2 l |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged or Turbocharged Aftercooled |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC+DPF |

Power Unit Dimensions

| Length | 39.1 in 992 mm |

|---|---|

| Width | 23.7 in 602 mm |

| Height | 38.8 in 985 mm |

| Weight | 721 lb 327 kg |

Standard Equipment

Control System

- Alternator 12 volt 85 amp

- Starter motor 12 volt

- Glow plug starting aid, delivers heat directly to cylinder for best starting performance in cold weather

- Electronic control unit - chassis mounted

- Flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

- Wiring harness connectors and sensors are waterproof and designed to withstand harsh off-highway environments

Flywheels and Flywheel Housing

- SAE No. 4 standard flywheel housing

- Choice of flywheel weight and bolting pattern to accommodate a range of industry-standard hydraulic pumps and transmissions

Fuel System

- 2000 bar high-pressure common rail system

- Proprietary fuel filters to ensure engine protection through correct service procedures, along with water-in-fuel detection, ensures maximum machine up-time for the operator

Lube System

- Alternative oil fillers

- Spin-on lube oil filter

Power Take Off (PTO)

- SAE A PTO drive

General

- Cast iron engine block

- Cast iron exhaust manifold

- Gradeability 35° continuous

- Paint: Cat yellow

Aftertreatment/Clean Emissions Control Equipment

- Diesel Oxidation Catalyst (DOC)

- Diesel Particulate Filter (DPF)