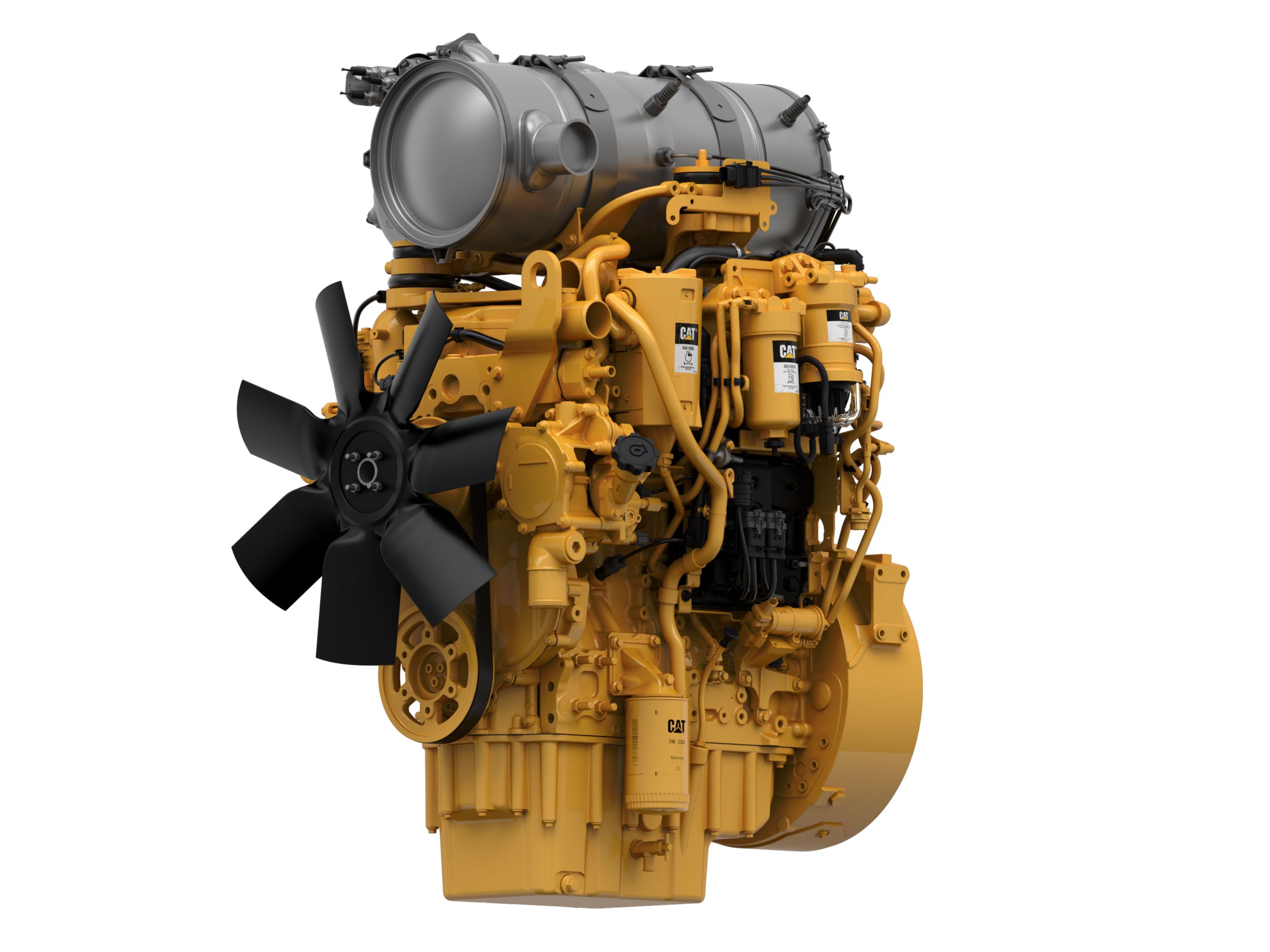

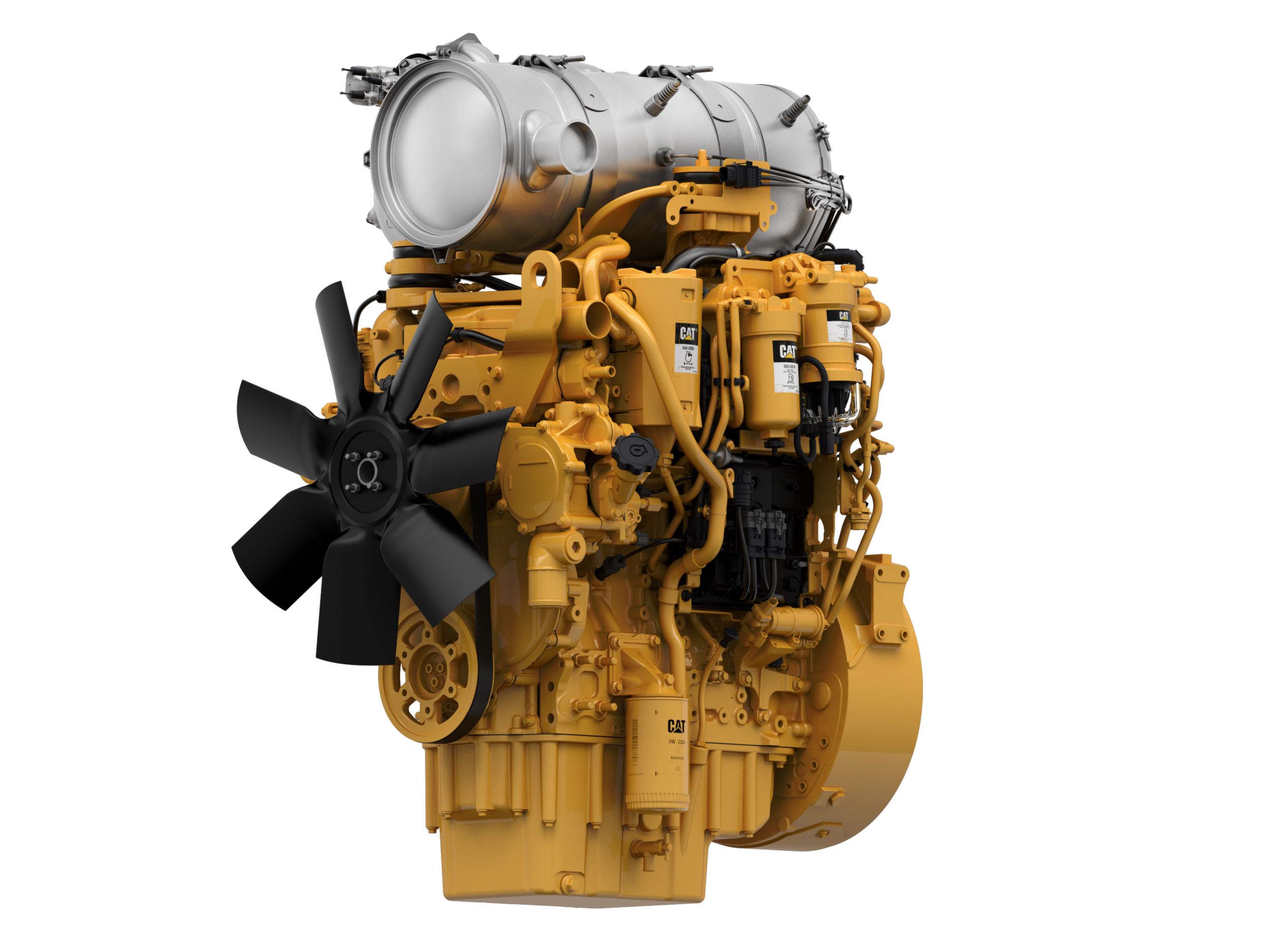

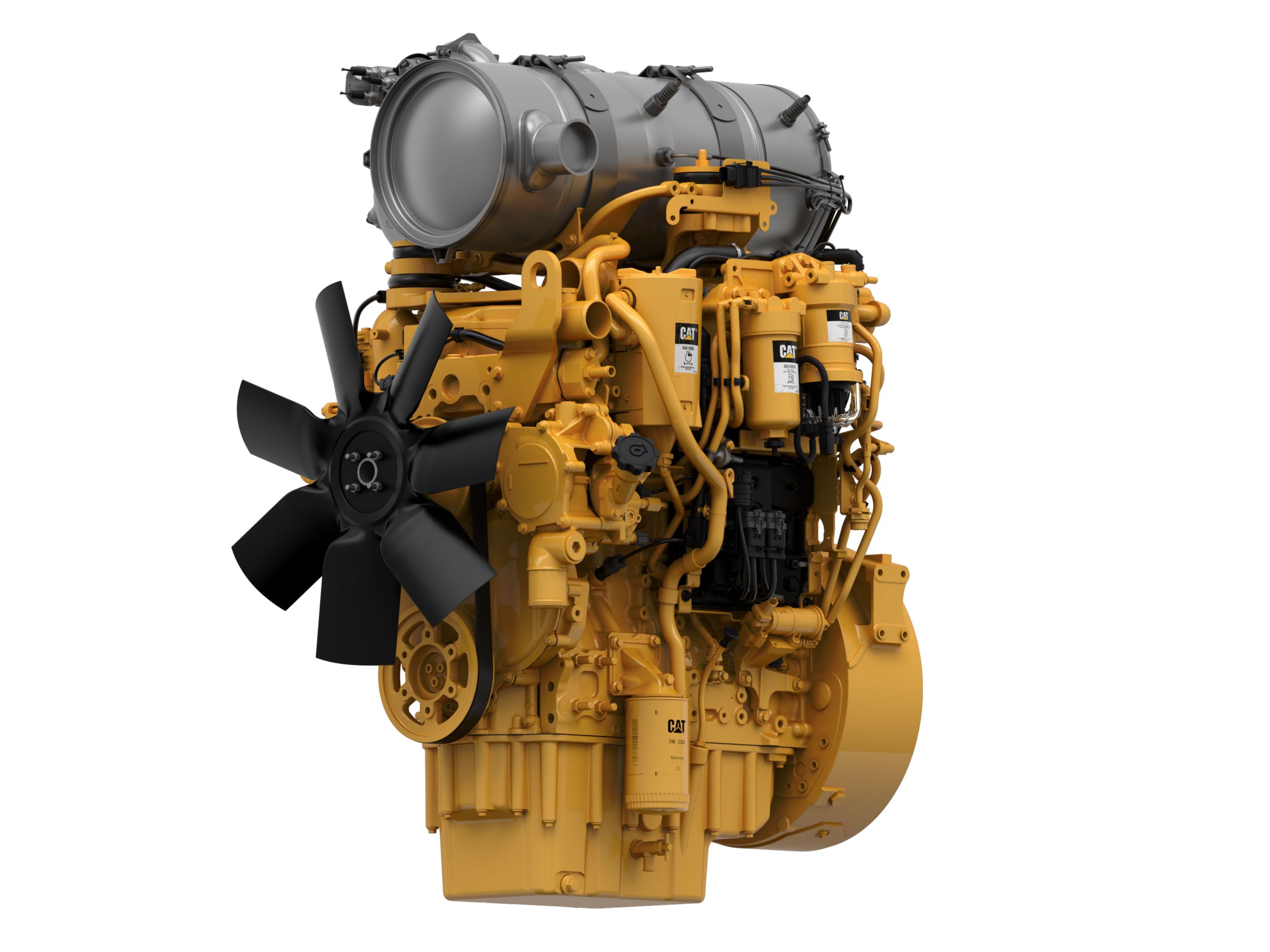

Cat™ C4.4 industrial diesel engines offer the perfect balance of durability, fuel efficiency and low emissions. Extensively tested on the job, these engines use a range of common rail fuel systems and advanced control systems to deliver maximum uptime in the harshest environment. They have proven they can handle the toughest applications and deliver superior performance that exceeds the expectations of the most demanding users. Industries and applications powered by C4.4 engines include: bore/drill rigs, chippers/grinders, material handling, mining, earthmoving equipment, paving equipment, pumps, fruit harvesters equipment, turf and underground mining equipment

Features

-

Installation

A modular and compact core on the Cat C4.4 makes installing the engine on any number of machine applications a relative breeze. And when downsizing from five-liter platforms, OEMs can see a 20% reduction in length, 5% reduction in height and 40% reduction in weight of the engine, significantly reducing installation costs.

-

Advanced Features

With a 20% increase in power density and 30% increase in torque when compared to its predcessor engine, the compact design of the Cat C4.4 reduces heat loss for more efficient engine output, so operators can conquer even the toughest tasks with relative ease.

-

Ideal Applications

Industrial, agricultural and construction applications such as: pumps • compressors • chippers • grinders • asphalt paving equipment • hydraulic power units • bore rigs • drill rigs • tractors.

-

Total Cost of Ownership

There’s a lot that can affect the lifetime cost of ownership of your engine. It can be as simple as fluid intake and as complex as weight distribution. Either way, the Cat C4.4 has it covered. When compared to similar 6-cylinder plaforms, the C4.4 saves more than 18% in fluid consumption and is specially balanced to be its most effective, every day.

-

Cat Dealer Product Support

The Cat C4.4 makes maintenance and service routines simple thanks to the worldwide Cat dealer network support. And for even more peace of mind, your Cat engine comes under warranty. See your Cat dealer for details.

-

Safety

Built-in clean emissions modules keep the Cat C4.4 performing at its peak while also keeping the air around the work site cleaner.

Specifications

Units for specifications

Power Rating

| Maximum Power | 173.5 hp 129.4 kW |

|---|---|

| Maximum Torque | 553 lb-ft @ 1400 rpm 750 Nm @ 1400 rpm |

| Rated Speed | 2000 to 2200 rpm |

| Minimum Power | 147.5 hp 110 kW |

Emission Standards

| Emissions | China Nonroad Stage IV |

|---|

General

| Engine Configuration | Inline 4, 4-Stroke-Cycle Diesel |

|---|---|

| Bore | 4.1 in 105 mm |

| Stroke | 5 in 127 mm |

| Displacement | 268.5 in³ 4.4 l |

| Compression Ratio | 16.5:1 |

| Aspiration | Turbocharged Aftercooled (TA) or Series Turbocharged Aftercooled (TTA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC+DPF+SCR |

Engine Dimensions - Approximate

| Length | 24.8 in 630 mm |

|---|---|

| Width | 29.4 in 748 mm |

| Height | 35.3 in 897 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 1179 lb 535 kg |

Aftertreatment Dimensions

| Length | 26.5 in 673 mm |

|---|---|

| Width | 16.2 in 411 mm |

| Height | 12.2 in 309 mm |

| Weight | 110 lb 50 kg |

Aftertreatment Dimensions*

| Diameter | 10.64 in 270.3 mm |

|---|

Standard Equipment

Air Inlet System

- Standard air cleaners

Control System

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

- Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

Cooling System

- Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

- 50:50 water glycol mix

Flywheels and Flywheel Housing

- Fitted with SAE3 configuration as standard

Fuel System

- Electronic high pressure common rail

- Innovative filter design to ensure maximum protection of the engine

Lube System

- Wide choice of sumps for different applications

Power Take Off

- SAE A and SAE B flanges on left-hand side. Additional SAE A flange available on left-hand side. Engine power can also be taken from the front of the engine on some applications. Factory fitted compressors are also available.

General

- Available with or without a balancer

- Paint: Caterpillar yellow, with optional colors available at request

China Nonroad Stage IV Aftertreatment / Clean Emissions Control Equipment

- Clean Emissions Module (CEM), consisting of Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC)

China Nonroad Stage IV Aftertreatment/ Clean Emissions Control Equipment

- Selective Catalytic Reduction (SCR)

- 3" flex pipe connection with straight, 45°, and 90° options for flexibility