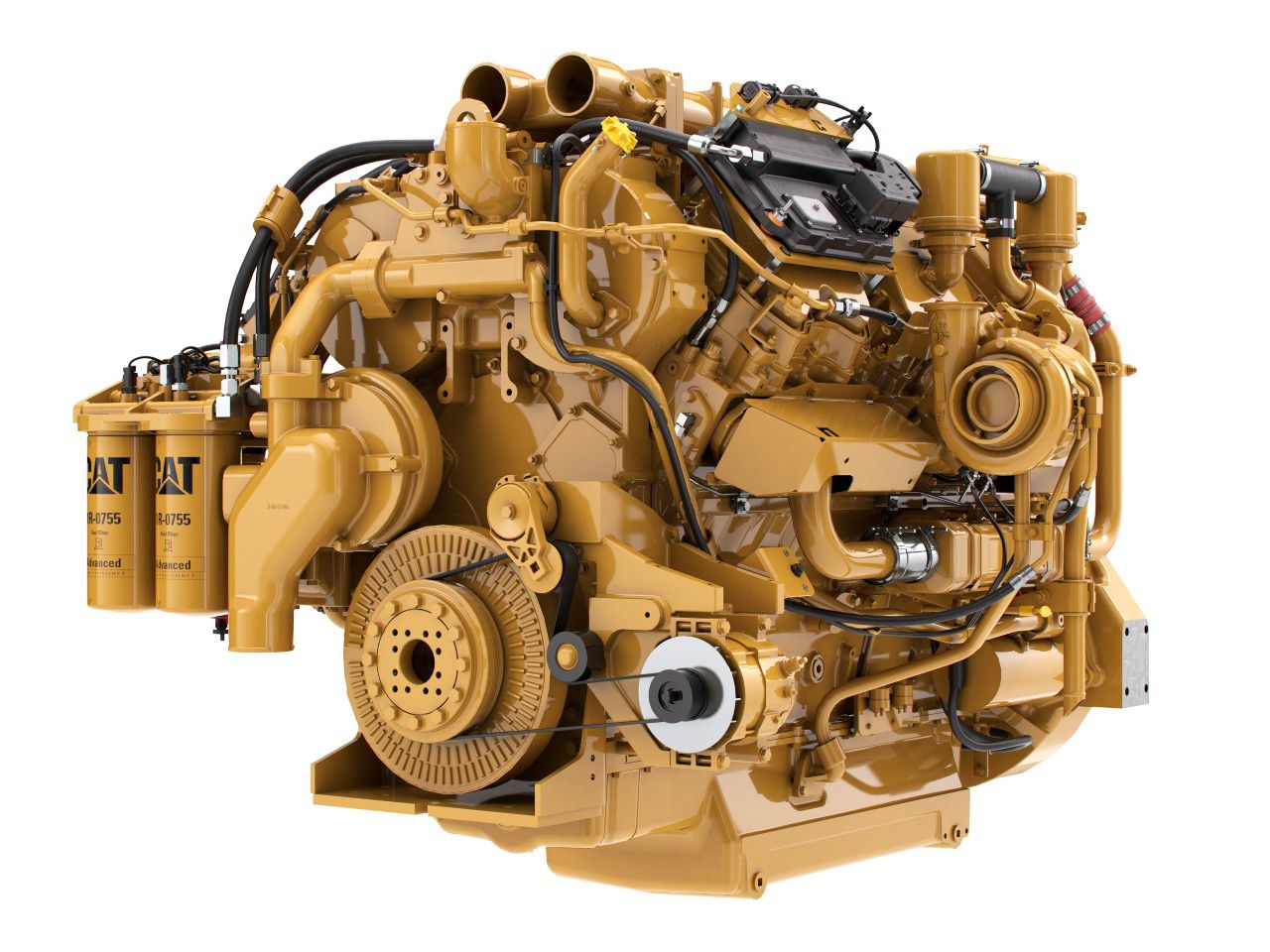

Building on the legacy of the C32, the C32B features strengthened

performance critical components like cylinder head, block,

crankshaft, pistons, rods, and main bearings. Its simple,

maintenance free diesel oxidation catalyst (DOC) aftertreatment

meets U.S. EPA Tier 4 Final, EU Stage V, and other equivalent

emissions standards

Features

-

High Power Density

C32B engines have excellent power density with a peak U.S. EPA Tier 4 Final certified rating of 895 kW (1200 hp) and 839 kW (1125 hp) for EU Stage V. Its U.S. EPA Tier 2 equivalent version offers a peak rating of 1007 kW (1350 hp).

-

Built to Last

The C32B uses a dual-can diesel oxidation catalyst (DOC) aftertreatment. This maintenance-free, passive aftertreatment solution eliminates the need for thermal management or regeneration. The C32B does not require diesel exhaust fluid (DEF), helping minimize total fluid consumption and eliminating the need for any DEF infrastructure (DEF tank, DEF pump, heated DEF lines, additional electronics, and DEF storage on the jobsite). DOC-only simplifies the aftertreatment solution, helps minimize overall package size, and reduces operation costs.

-

DOC only Aftertreatment

The C32B boasts strength from the inside out. Weighing approximately 50 kg (110 lb) more than its predecessor, the C32B’s performance critical components have been strengthened and upgraded to help extend time between rebuilds.

Specifications

Units for specifications

Power Rating

| Maximum Power | 1200 hp 895 kW |

|---|---|

| Maximum Torque | 4056 lb-ft @ 1200 rpm 5499 Nm @ 1200 rpm |

| Rated Speed | 1800 rpm |

| Minimum Power | 1000 hp 746 kW |

Emission Standards

| Emissions | EU Stage V |

|---|

General

| Engine Configuration | V-12 |

|---|---|

| Bore | 5.7 in 145 mm |

| Stroke | 6.4 in 162 mm |

| Displacement | 1958.9 in³ 32.1 l |

| Compression Ratio | 15.0:1 |

| Aspiration | Twin Turbocharged Aftercooled (TTA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC |

Engine Dimensions - Approximate

| Length | 73.8 in 1874 mm |

|---|---|

| Width | 63 in 1600 mm |

| Height | 53.9 in 1370 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 6735 lb 3055 kg |

Aftertreatment Dimensions

| Length | 45.5 in 1156 mm |

|---|---|

| Width | 17.3 in 440 mm |

| Height | 16 in 407 mm |

| Weight | 150 lb 68 kg |

Standard Equipment

Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

Cooling System

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Water pump, inlet

Exhaust System

- Exhaust manifold, dry

- Optional exhaust outlet

Flywheels and Flywheel Housing

- Choice of SAE No. 0 or SAE No. 1 flywheel housing

Fuel System

- MEUI injection

- Fuel filter, secondary (2 micron)

- Electronic fuel priming

Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Rear sump oil pan

- Oil dipstick

- Gear driven oil pump

General

- Paint: Caterpillar yellow, with optional colors available on request