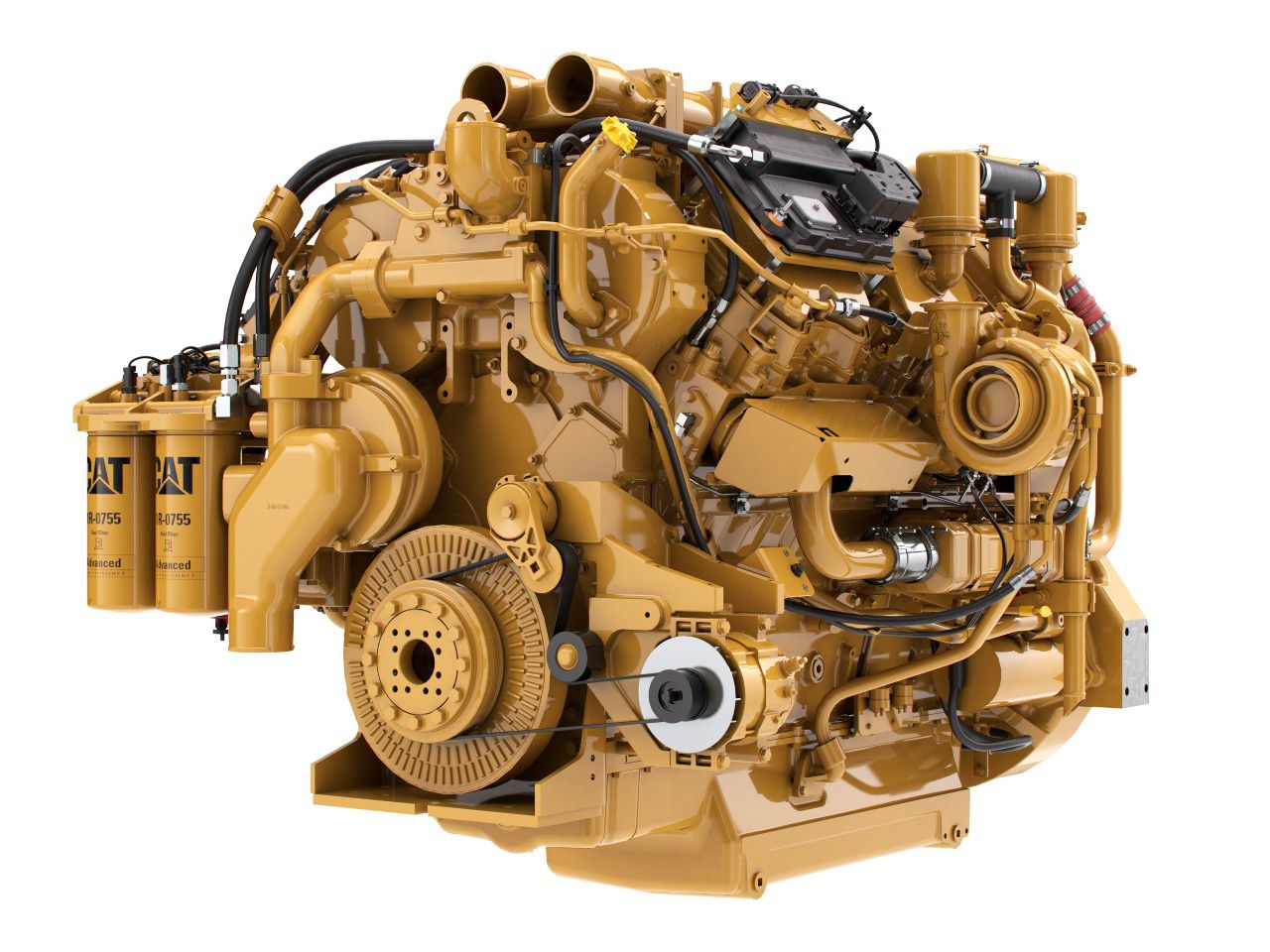

The Cat™ C32 Industrial Diesel Engine is offered in ratings ranging from 746-895 bkW (1000-1200 bhp) @ 1800 rpm. These ratings meet U.S. EPA Tier 4 Final emission standards. Applications powered by C32 engines include: Bore/Drill Rigs, Chippers/Grinders, Construction, Cranes, Dredgers, Forestry, Hydraulic Power Units, General Industrial, Irrigation Equipment, Material Handling, Mobile Earthmoving Equipment, Paving Equipment, Pumps, Shovels/Draglines, Surface Hauling Equipment and Trenchers.

Features

-

Installation

When it comes to making the engine installation process smoother, look to the Cat C32. Using innovative technology solutions, the C32 was created to eliminate the need for thermal management and DEF, reducing the size of the overall engine package. And thanks to flexible aftertreatment mounting options, installing such a large engine just got a lot less complicated.

-

Advanced Features

The key to success for any machine is avoiding downtime as much as possible. Thanks to the DEF-free, the dual-can DOC Cat C32 with transparent regeneration, operators can stay focused on being productive for the long haul.

-

Ideal Applications

Industrial and construction applications such as: Dredges • Chippers • Grinders • Emergency water pumps • Rock drills

-

Total Cost of Ownership

Optimized to meet some of the most demanding operating cycles of just about any machine, the DEF-free Cat C32 can help owners and operators save on parts costs while also remaining maintenance-free for the engine’s lifetime.

-

Cat Dealer Product Support

Bigger is better and that’s because the Cat C32 comes standard with a world-class global dealer network support and simplified service routines. Not to mention an included warranty. See your Cat dealer for details.

-

Safety

Built to meet Caterpillar’s strict safety standards and customers’ most demanding work sites throughout the world, the Cat C32 is tried and tested to be safe and secure no matter where the job site is.

Specifications

Units for specifications

Power Rating

| Maximum Power | 1200 hp 895 kW |

|---|---|

| Maximum Torque | 4056 lb-ft @ 1200 rpm 5499 Nm @ 1200 rpm |

| Rated Speed | 1800 rpm |

| Minimum Power | 1000 hp 746 kW |

Emission Standards

| Emissions | U.S. EPA Tier 4 Final |

|---|

General

| Engine Configuration | V-12 |

|---|---|

| Bore | 5.7 in 145 mm |

| Stroke | 6.4 in 162 mm |

| Displacement | 1958.9 in³ 32.1 l |

| Compression Ratio | 15.0:1 |

| Aspiration | Twin Turbocharged Aftercooled (TTA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | DOC |

Engine Dimensions - Approximate

| Length | 73.8 in 1874 mm |

|---|---|

| Width | 63 in 1600 mm |

| Height | 53.9 in 1370 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 6625 lb 3004 kg |

Standard Equipment

Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

Cooling System

- Thermostats and housing, vertical outlet

- Jacket water pump, centrifugal

- Water pump, inlet

Exhaust System

- Exhaust manifold, dry

- Optional exhaust outlet

Flywheels and Flywheel Housing

- Choice of SAE No. 0 or SAE No. 1 flywheel housing

Fuel System

- MEUI injection

- Fuel filter, secondary (2 micron)

- Electronic fuel priming

Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Rear sump oil pan

- Oil dipstick

- Gear driven oil pump

General

- Paint: Caterpillar yellow, with optional colors available at request