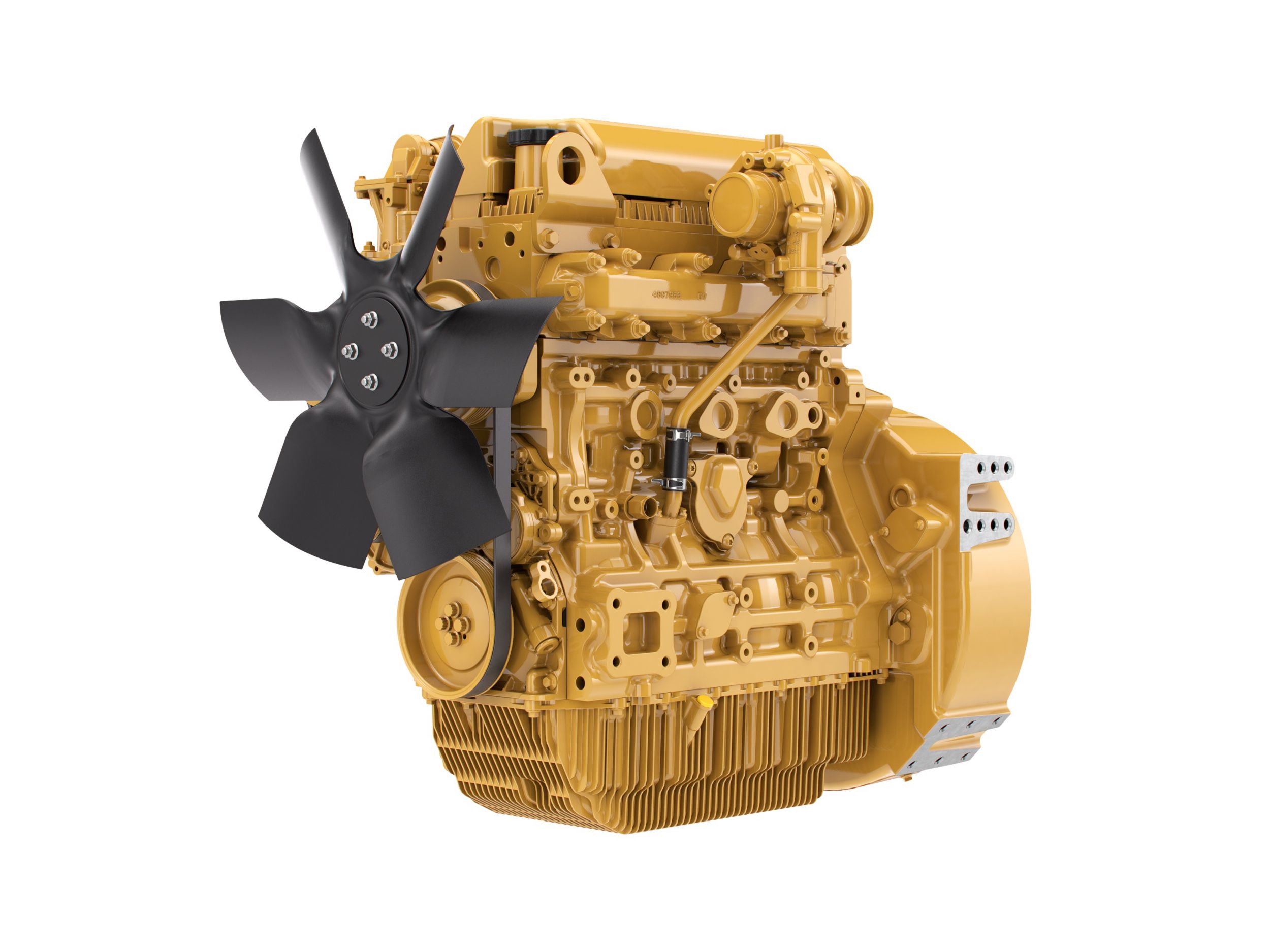

The Cat™ C2.8 Industrial Diesel Engines offer the perfect balance of compact size, reliability, and performance. This engine is offered in ratings ranging up to 55 bkW (74 bhp) @ 2500 rpm. The C2.8 is designed to meet the needs of many industries and applications, including agricultural tractors, aerial lifts, aircraft ground support, bore/drill rigs, chippers/grinders, compactors/rollers, compressors, forestry, irrigation equipment, material handling, mining, earthmoving equipment, paving equipment, pumps, fruit harvesters equipment, turf and underground mining equipment.

Features

-

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven technologies and extensive field validation assure reliability and durability in tough nonroad applications.

-

High Performance

Leading edge fuel systems and turbocharging provide high torque even at lower engine speeds.

-

Fuel Efficiency

Fuel consumption optimized to match the measured operating cycles of a wide range of equipment types.

-

Broad Application Range

Industry-leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

-

Low Cost Maintenance

Worldwide service delivers ease of maintenance and simplifies the servicing routine. Capable of optimal oil change intervals of 500 hours. The S•O•S℠ program is available from your Cat dealer to determine oil change intervals and provide optimal performance.

-

Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

-

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOS℠ sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Specifications

Units for specifications

Power Rating

| Maximum Power | 74 hp 55 kW |

|---|---|

| Maximum Torque | 221 lb-ft @ 1600 rpm 300 Nm @ 1600 rpm |

| Rated Speed | 2200-2400 rpm |

| Minimum Power | 67 hp 50 kW |

Emission Standards

| Emissions | UN ECE R96 Stage IIIA, Brazil MAR-1 |

|---|

General

| Engine Configuration | Inline 4, 4-Stroke-Cycle Diesel |

|---|---|

| Bore | 3.5 in 90 mm |

| Stroke | 4.3 in 110 mm |

| Displacement | 171 in³ 2.8 l |

| Compression Ratio | 17.0:1 |

| Aspiration | Turbocharged (T) and Turbocharged Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | - |

Engine Dimensions - Approximate

| Length | 24.9 in 633 mm |

|---|---|

| Width | 21.2 in 538 mm |

| Height | 30.9 in 786 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 705 lb 320 kg |

Standard Equipment

Air Inlet System

- Induction manifolds

- Exhaust manifolds

Control System

- Starter motor (12V or 24V)

- Alternator (12V or 24V)

- Electronic Control Unit (chassis mounted)

- Engine control sensors and robust wiring harness

- Data interface via CANbus J1939

Flywheels and Flywheel Housing

- Flywheel housings – SAE 3 or SAE 4

- Choice of flywheel to match industry common hydraulic pumps and transmissions

- Side PTO with SAE A or SAE B interface

Fuel System

- Fuel filter – preconnected but chassis mounted

- With water sensor

Lube System

- Lubricating oil filters

- High incline oil pan – 35° continuous in all directions

General

- Cold start capability to -20° C (-4° F) with standard equipment

- Paint: Caterpillar yellow, with optional colors available at request