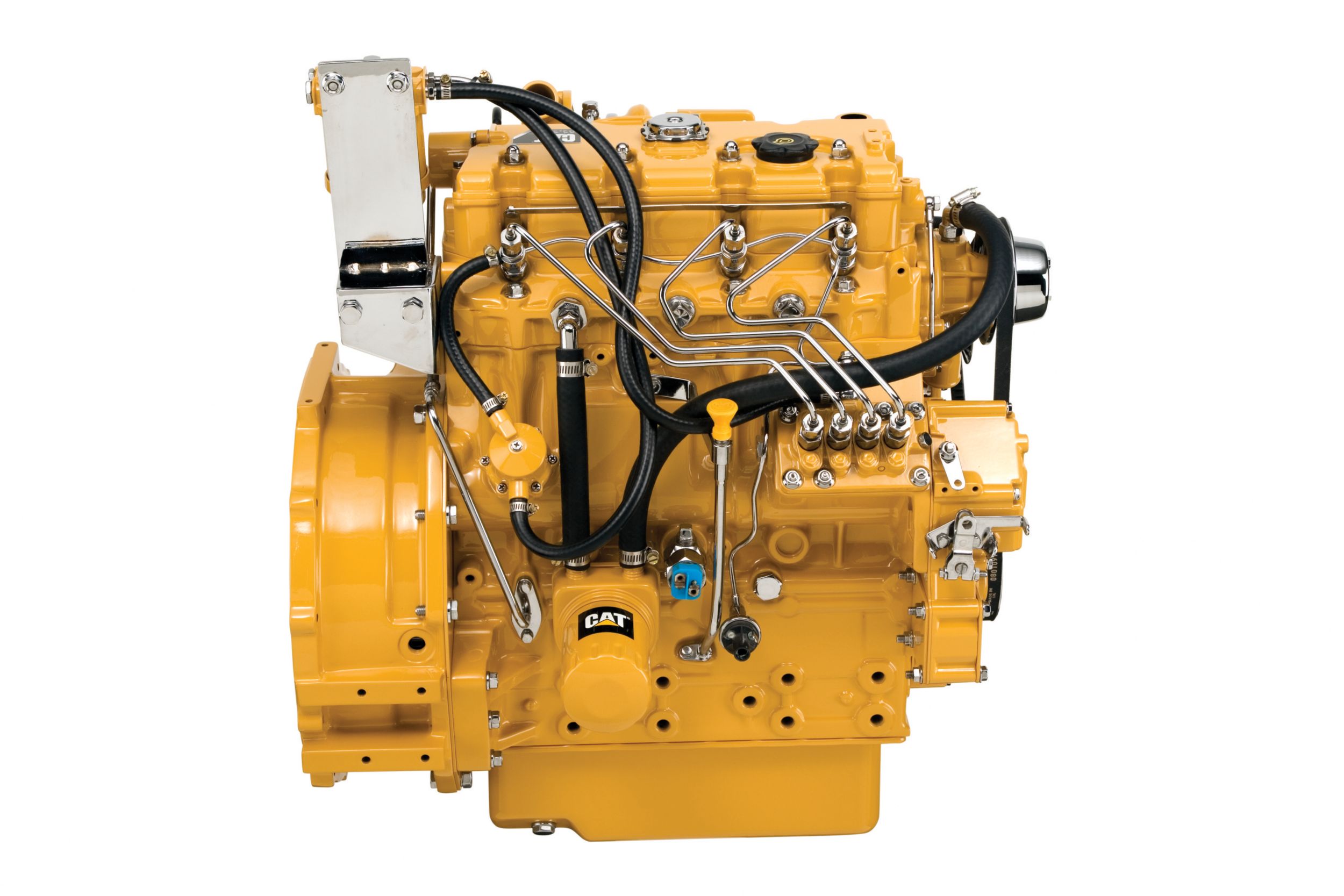

The Cat™ C2.2 Industrial Diesel Engine is offered in ratings ranging from 31-49.3 bkW (41.6-66.1 bhp) @ 2200-3000 rpm. These ratings meet EU Stage IIIA (U.S. EPA Tier 4 Interim equivalent) emission standards. Industries and applications powered by C2.2 engines include: Agriculture, Aerial Lifts, Bore/Drill Rigs, Chippers/Grinders, Compactors/Rollers, Compressors, Construction, General Industrial, Irrigation Equipment, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Light Towers, Mobile Sweepers, Paving Equipment, Pumps, Trenchers, Turf and Landscaping, Underground Mining Equipment and Welders.

Features

-

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

-

High Performance

Substantial torque rise delivers impressive performance throughout a wide speed range while maintaining low operating costs.

-

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

-

Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

-

Package Size

Ultra-compact package size ensures ease of installation as well as exceptional power density.

-

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Specifications

Units for specifications

Power Rating

| Maximum Power | 66 hp 49.2 kW |

|---|---|

| Maximum Torque | 153 lb-ft @ 1800 rpm 208 Nm @ 1800 rpm |

| Rated Speed | 2200-3000 rpm |

| Minimum Power | 41.6 hp 31 kW |

Emission Standards

| Emissions | U.S. EPA Tier 4 Interim Equivalent |

|---|

General

| Engine Configuration | Inline 4, 4-Stroke-Cycle Diesel |

|---|---|

| Bore | 3.3 in 84 mm |

| Stroke | 3.9 in 100 mm |

| Displacement | 135 in³ 2.216 l |

| Compression Ratio | 23.3:1 |

| Aspiration | Naturally Aspirated (NA), Turbocharged (T) or Turbocharged Aftercooled (TA) |

| Combustion System | Indirect Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | - |

Engine Dimensions - Approximate

| Length | 26 in 662 mm |

|---|---|

| Width | 19.3 in 489 mm |

| Height | 27.5 in 698 mm |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 427.7 lb 194 kg |

Standard Equipment

Air Inlet System

- Inlet manifold with choice of inlets.

Control System

- Alternator 12 volt 65 amp

- Starter motor 12 volt

- Glow plug starting aid

Cooling System

- Belt-driven coolant pump

- Coolant temperature switch

- Choice of cooling fans

Flywheels and Flywheel Housing

- SAE No. 7 1/2, SAE No. 8 or SAE No. 10 flywheel

- Choice of SAE No. 4 or standard backplate flywheel housing

Fuel System

- Fuel injection pump

- Spin-on fuel filter

- Electronic Shut-off Solenoid (ESOS)

Lube System

- Alternative oil fillers

- Spin-on lube oil filter

- Lube oil pressure switch

- Lube oil sump

General

- Cast iron, engine block

- Cast iron exhaust manifold--side outlet

- Cold start capability to -20° C (-4° F)

- Gradeability 35° continuous

- Paint: Caterpillar yellow, with optional colors available at request