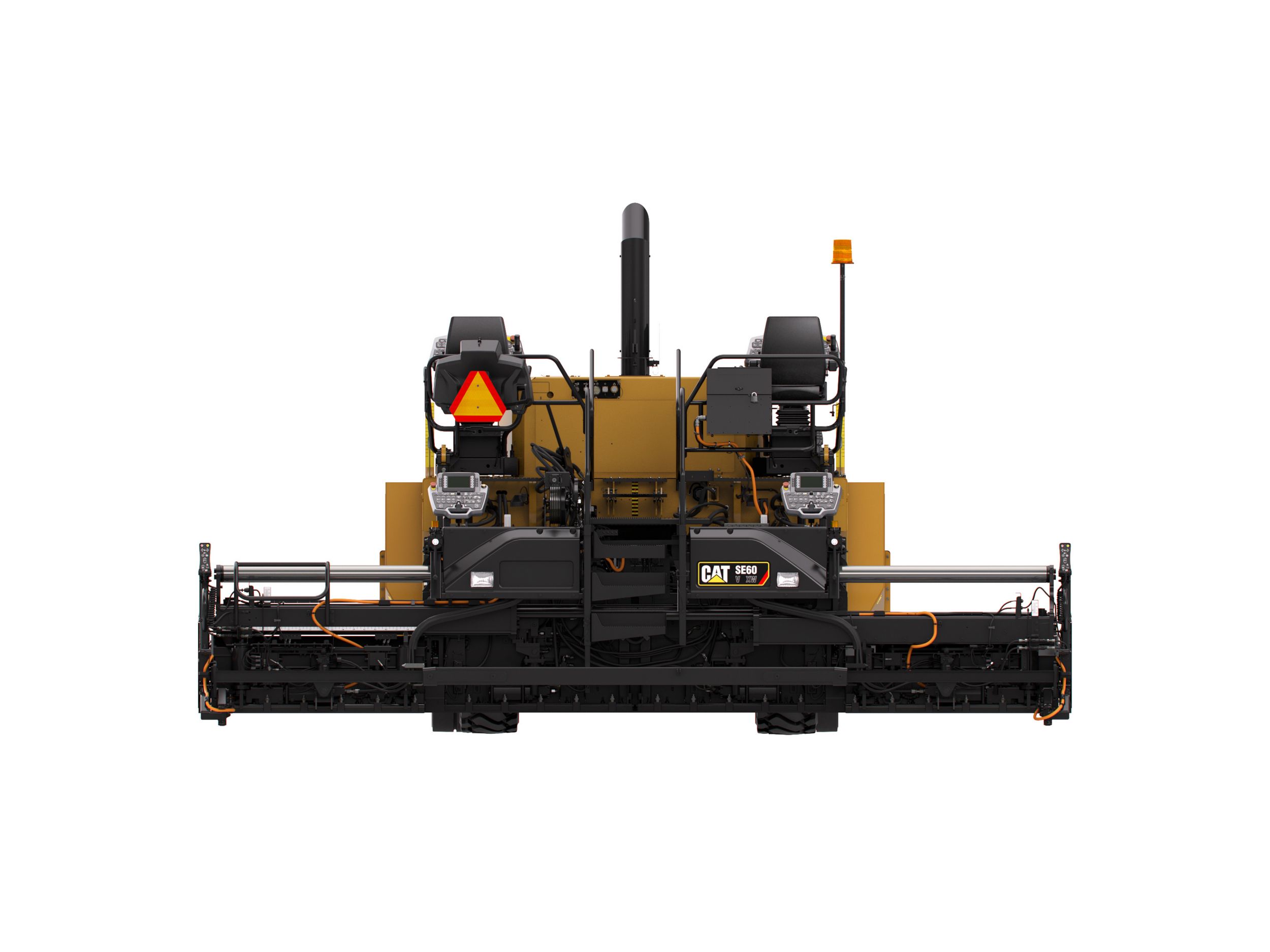

The SE60 V XW delivers extremely tight mat textures with high densities. It utilizes rear-mounted extenders, vibratory screed plates and has a paving range of 3.0 m to 10.0 m (9′ 10″ – 33′). It excels on interstates, highways, airport runways and other wide-width applications.

Features

-

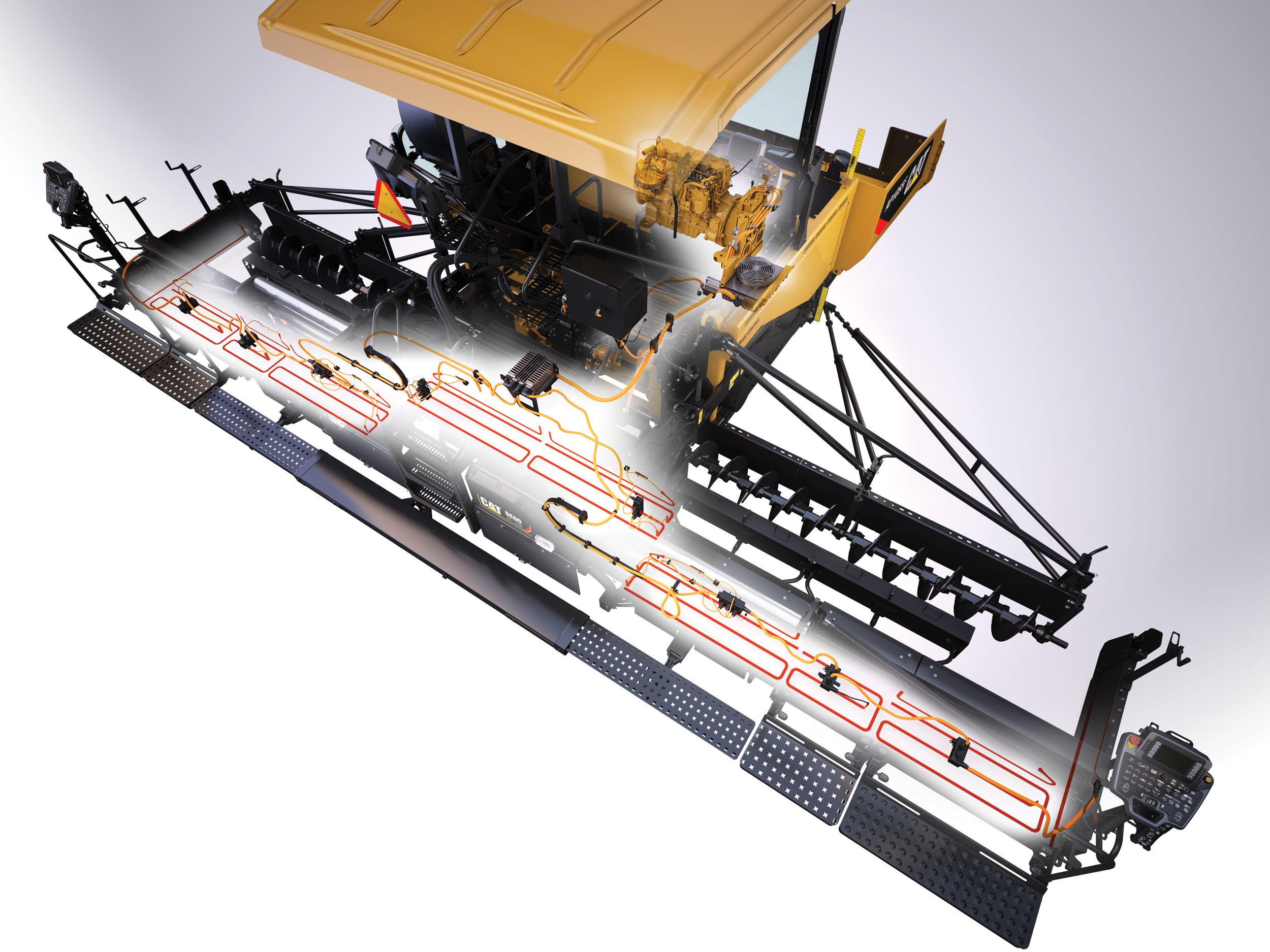

Fast Heating

The 70 kW, tractor integrated generator combined with the technologically advanced screed heating system, ensures fast, even heat distribution. The 15 minute heating time at standard widths can lead to more daily production and lower fuel consumption due to less time waiting for the screed plates to reach the preset temperature.

-

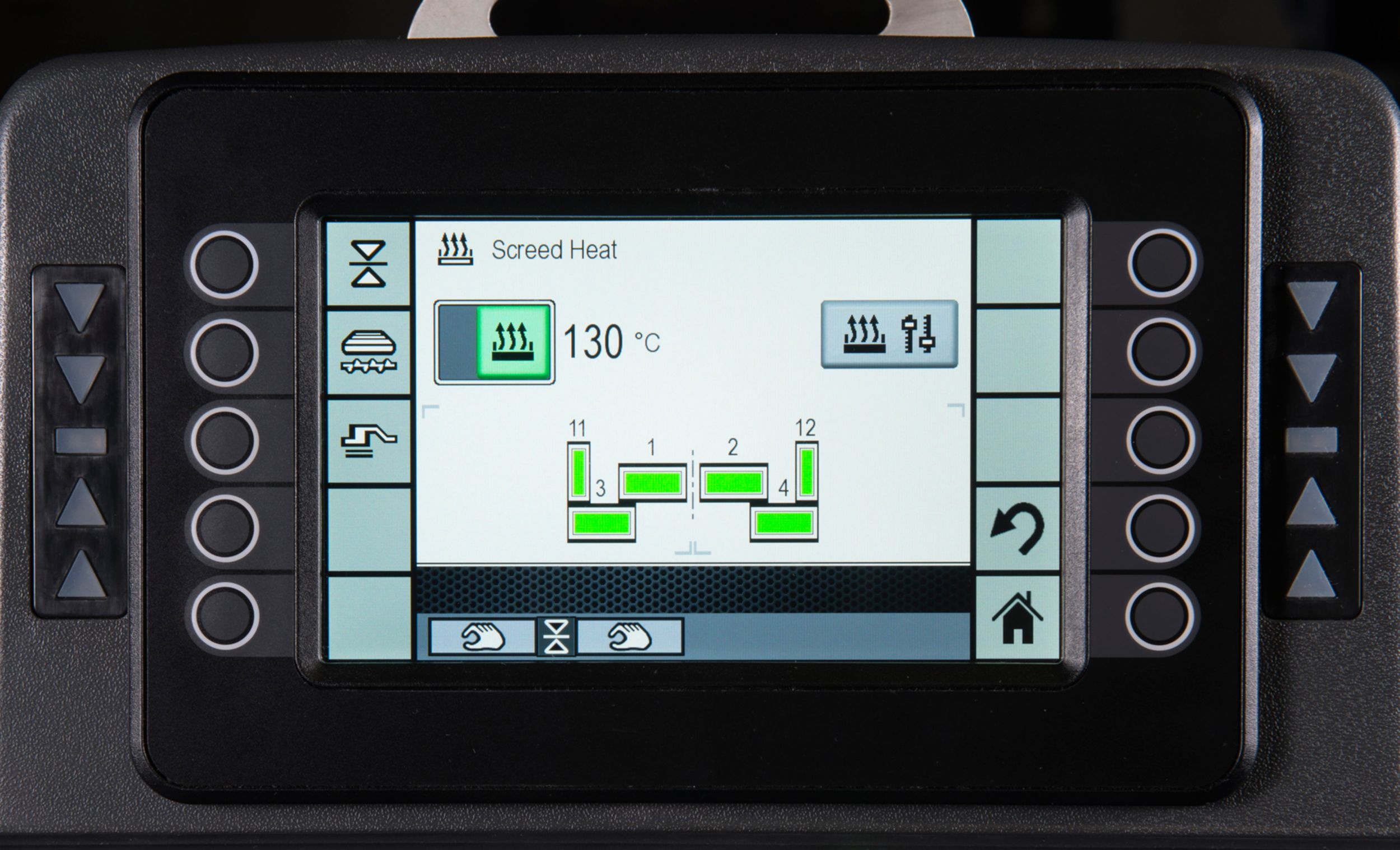

Exclusive Monitoring

The exclusive generator system monitors heating elements for failure conditions in order to help plan for scheduled service events. Furthermore, temperature zone monitoring allows heating to continue in the event of a sensor failure and warning indicators are delivered through the LCD displays.

-

More Control

The extenders are equipped with 2 speed ranges and proportional control for better performance around obstacles. Pendant control located on the extenders enable operators to perform functions remotely. The conveyor ratio adjustment can be made from the screed control panel when utilizing the 2-sensor feeder system in order to maintain optimal material height in front of the screed.

-

Integrated Cat Grade Control

Factory integrated Cat Grade Control allows the crew to operate from either of the tractor or screed consoles. A split screen mode enables the screed operators to work from a single side or from each side of the screed. This is especially helpful when training new operators and when the crew is tasked with multiple job site duties.

-

Simple Adjustment

Power controls for crown, slope, and height allow for on-the-go adjustment at standard and maximum widths. The exclusive trailing edge screed plate adjusters as well as machined screed frames help optimize plate life and simplify leveling procedures.

-

Easy Service, Increased Durability

Water resistant consoles and LCD displays ensure performance in adverse conditions and the million-cycle keypad switches and oil-bath vibratory pods provide longterm reliability. The heating elements slide out for easy replacement.

-

Extra Wide Paving Packages

The SE60 V XW can be equipped with extension packages that pave up to 10.0 m (33′). Power controls for crown, slope, and extension height provide easy adjustment for better mat textures and quality. An exclusive fastening system utilizes power controls to attach the extensions, eliminating the need for additional lifting devices.

Specifications

Units for specifications

Dimensions

| Transport Width - Endgates Folded | 9.85 ft 3000 mm |

|---|---|

| Screed Plate Width - Front to Back | 16 in 407 mm |

| Length - Front to Back, Endgates Removed | 76 in 1940 mm |

| Transport Length - Tractor and Screed | 22.6 ft 6910 mm |

| Length - Front to Back, Endgates Attached | 98 in 2499 mm |

Weights

| Standard Weight | 8973 lb 4070 kg |

|---|

Operating Specifications

| Standard Paving Range | 3.0 to 6.0 m (9' 10"- 19' 6") |

|---|---|

| Maximum Paving Width | 33 ft 10 m |

| Extender Height Range | -20 mm to +50 mm |

| Crown Range | -4% to +10% |

| Vibratory Speed Range | 0 - 3000 rpm |

| Maximum Paving Depth | 12 in 305 mm |

| Extender Slope Range | -3% to +10% |

| Heating Time - Standard Width | 15 minutes |

| Heating Time - Maximum Width | 25 minutes |

Videos

-

Cat® SDX Screed Plate System -

Cat® SDX Screed Plate Animation -

Cat® SDX Screed Plate Testimonial -

Cat® SDX Screed Plate System Installation Overview