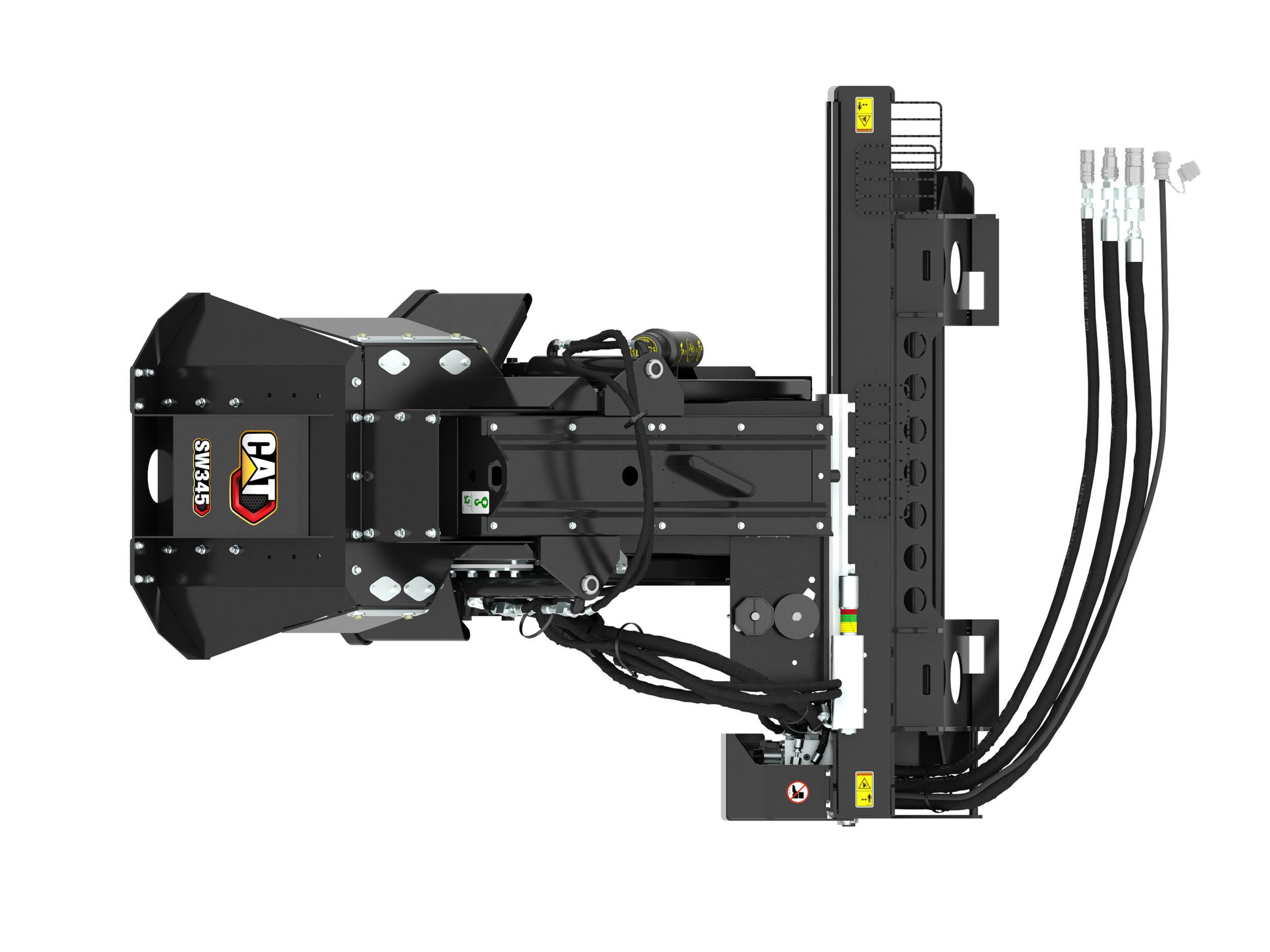

SW345, 80 mm (3 in) Wheel Saw

- Maximum Cutting Depth

- 17.7 in

- Wheel Width

- 3.1 in

- Weight

- 2482.4 lb

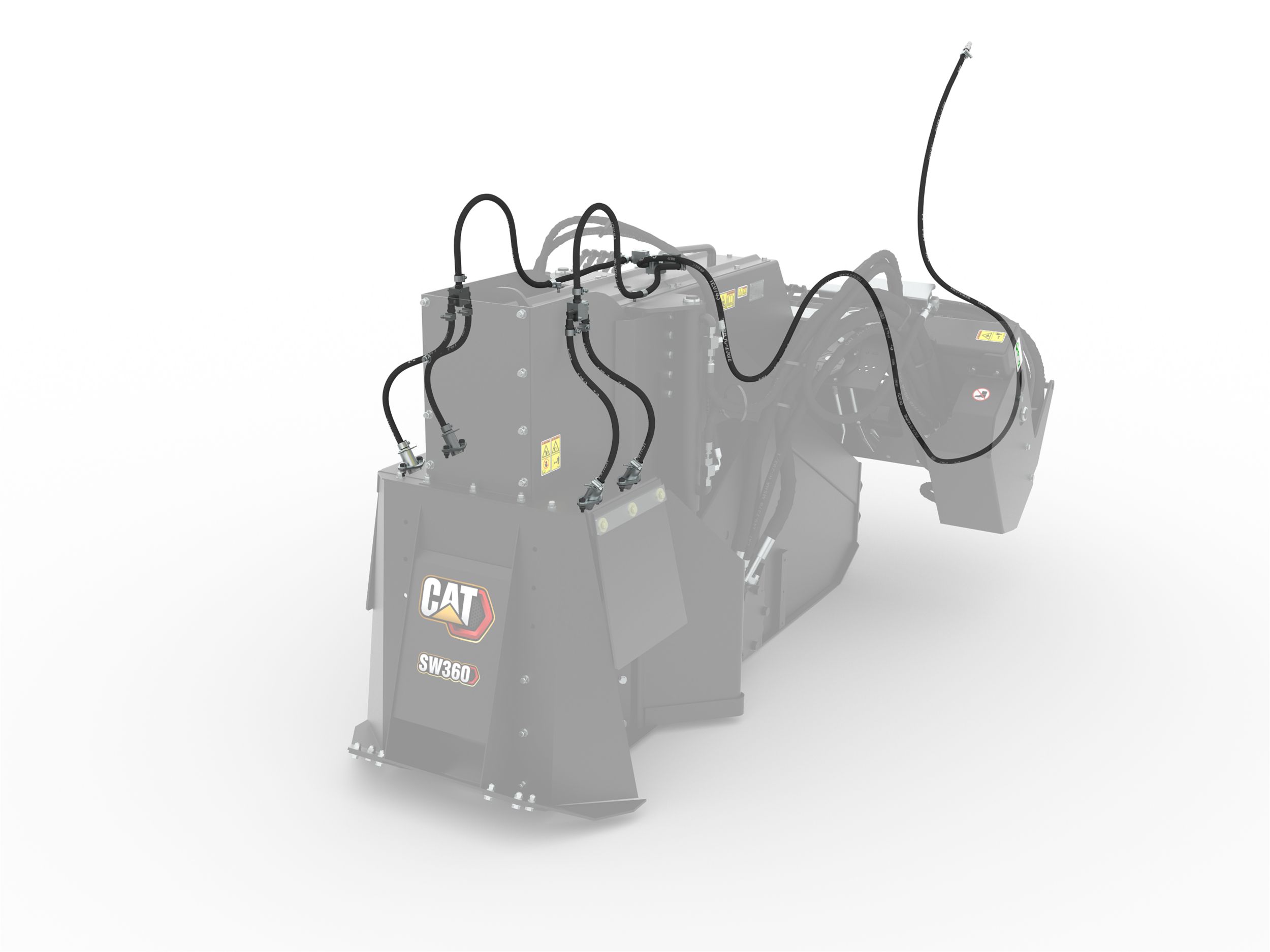

Cat® Wheel Saws are designed for high performance trench cutting on a variety of hard or compact surfaces such as asphalt, reinforced concrete, and rocky or frozen ground.

Features

-

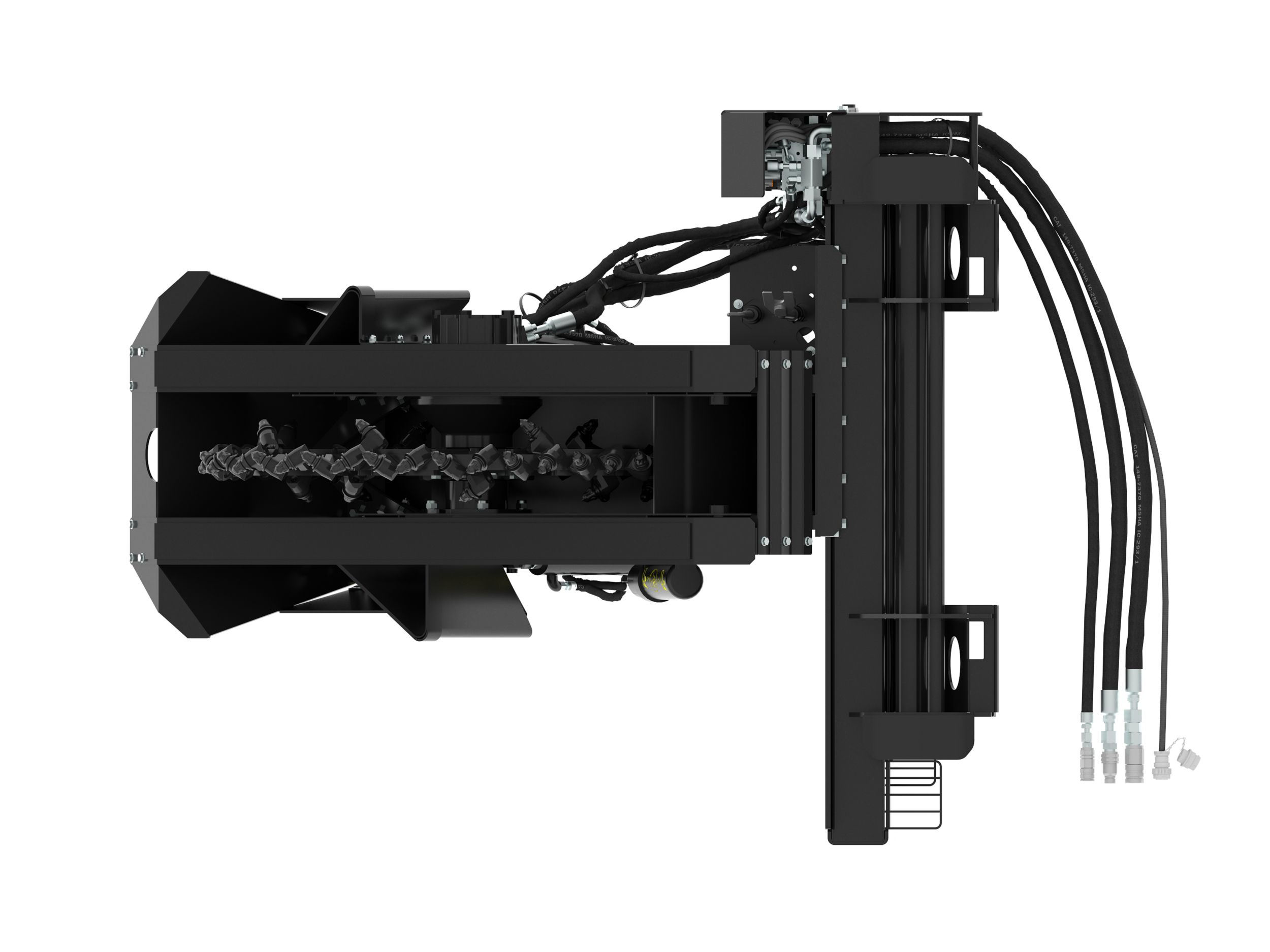

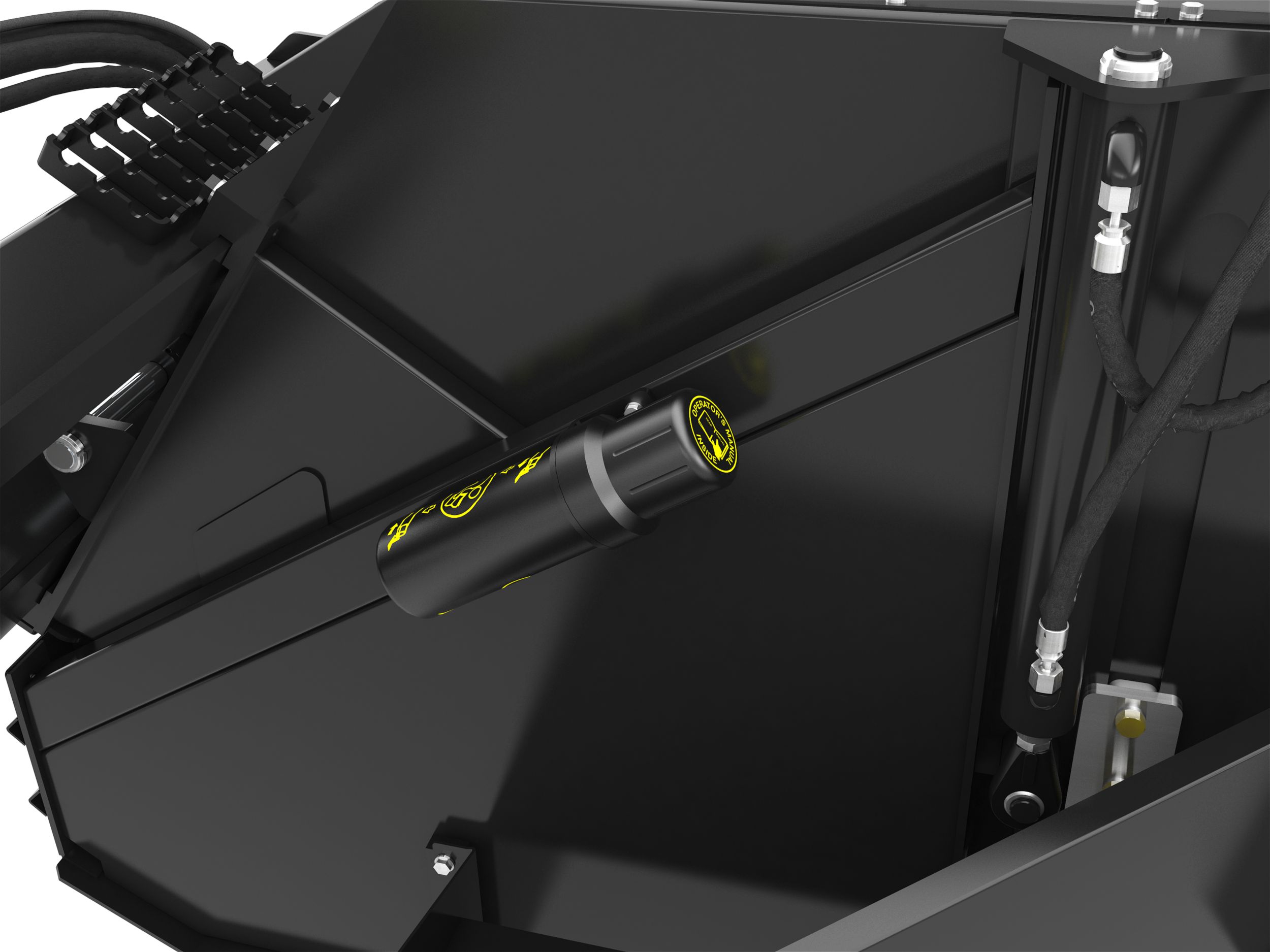

Direct Drive System

Direct drive system features a hydraulic piston pump motor to ensure maximum cutting rate and wheel torque for optimal production performance and efficiency.

-

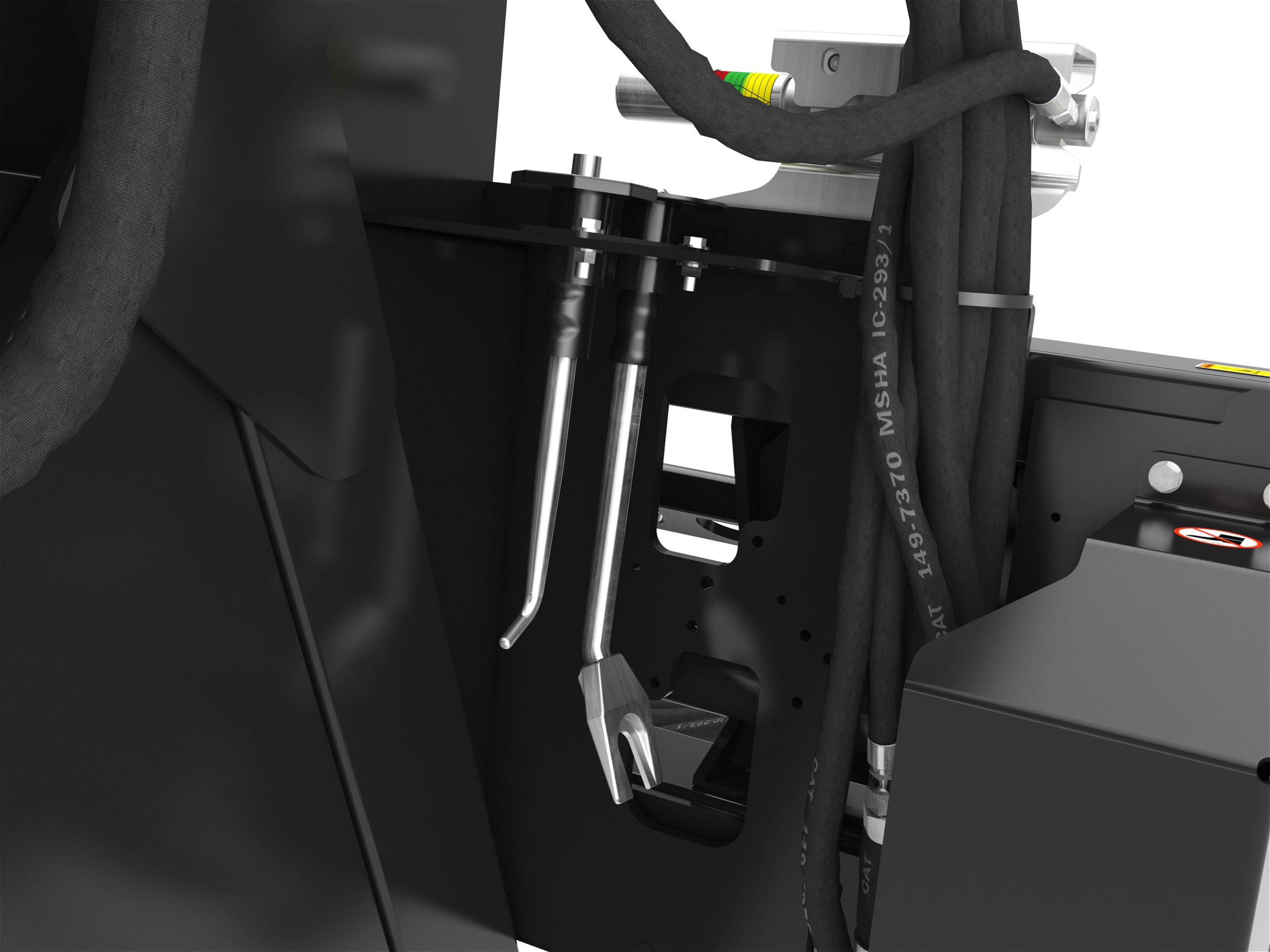

Hydraulic Side-Shift

Hydraulic side-shift is standard on all models and is controlled from the operator’s compartment. Hydraulic side-shift allows wheel positioning from center to the far right of center. This allows for cutting close to curbs, walls and other obstructions, and minimizes need to reposition the machine.

-

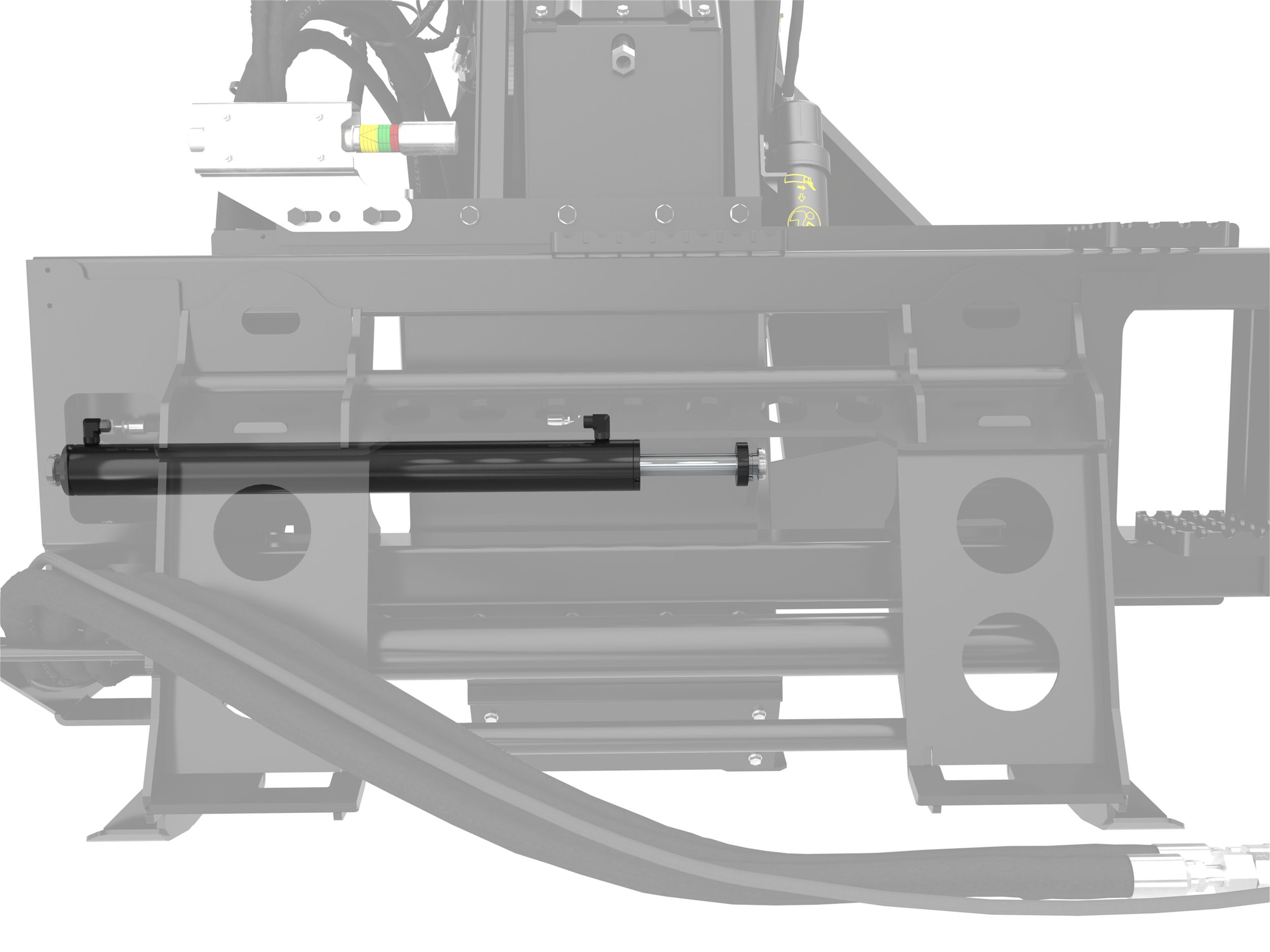

Hydraulic Depth Control

Hydraulic depth control is standard on all models and is controlled from the operator’s compartment. Hydraulic depth control allows the operator to adjust cut depth on the fly from in cab to quickly adjust to the current job as needed.

-

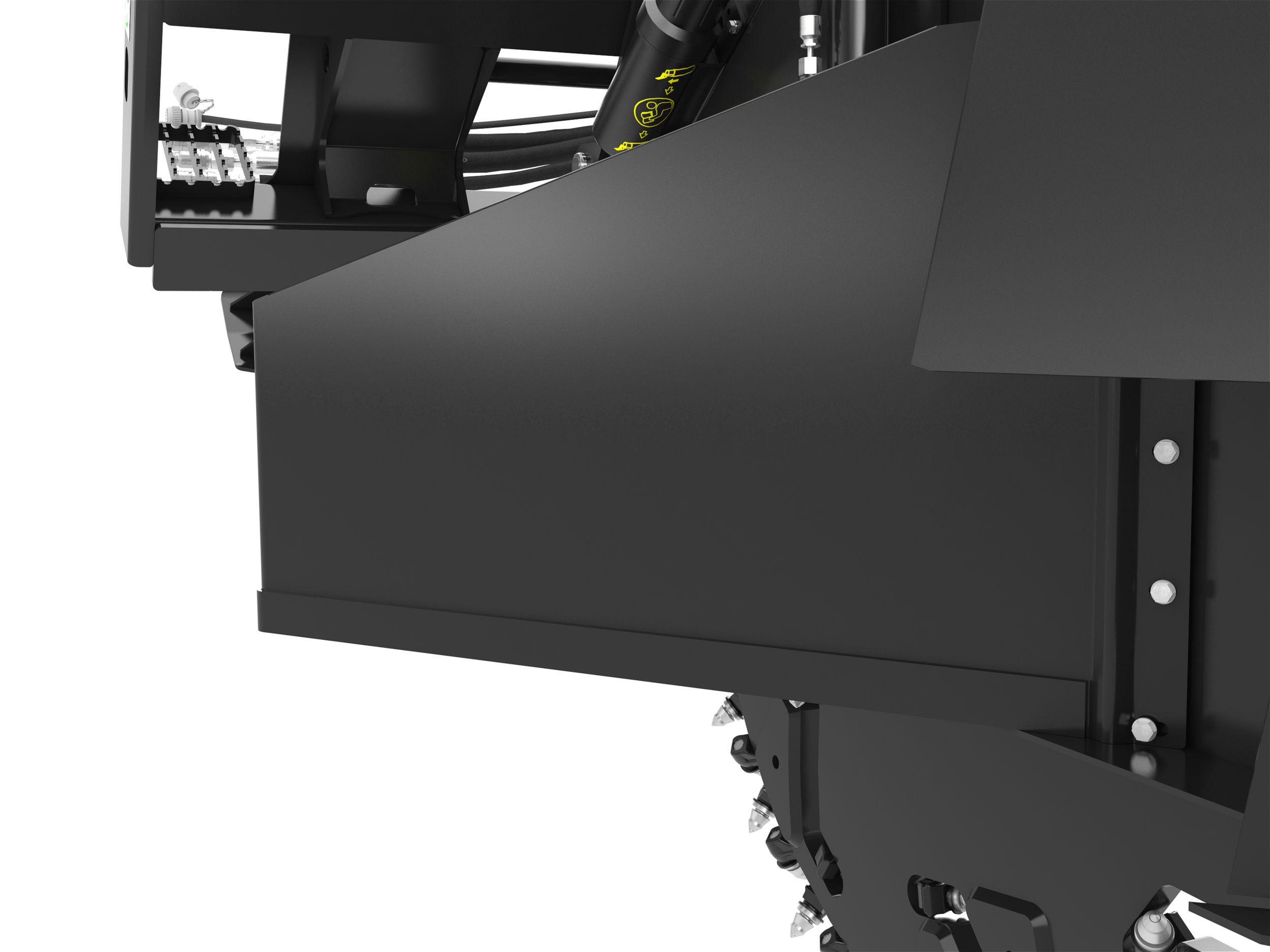

Deflector Plates

Deflector plates remove spoil from the machine’s path for smooth operation. Spoil can be discharged left, right, or on both sides of the wheel saw with installation of included blanking plates.

-

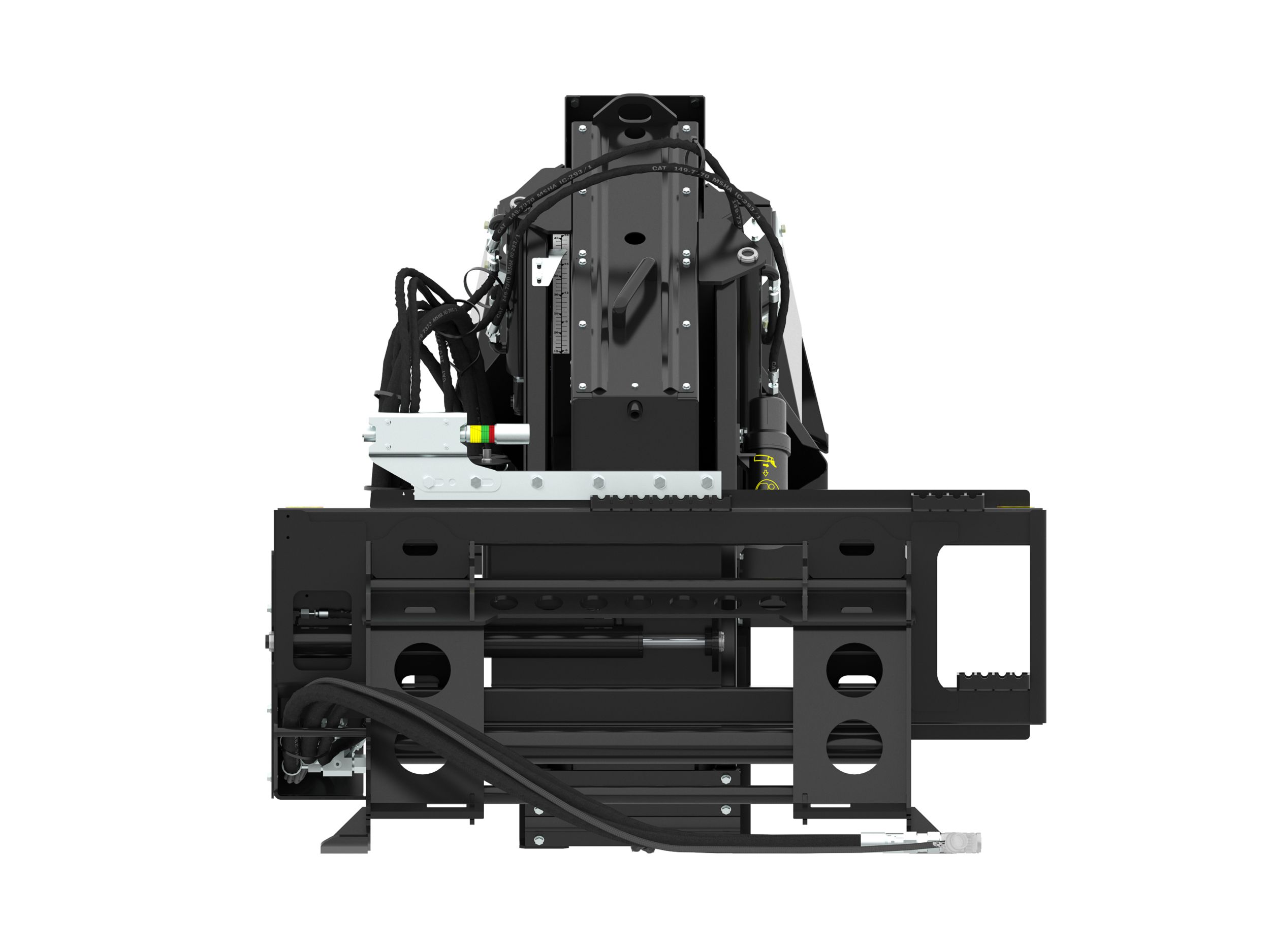

Max Pro Pressure Gauge

Max Pro Pressure Gauge provides operator feedback to adjust speed for maximum productivity in changing material loads. Gauge displays planer performance in real-time conditions and is visible from the cab. Standard on all models.

-

Bits

Concrete bits are standard on all models. Optional all purpose conical bits are available for all Cat Wheel Saws for tarmac and asphalt applications. Extreme life bits are available for extreme duty Cat Wheel Saw applications.

-

Self Standing

Self standing frame design improves connection and parking.

-

OMM Container

Stores the OMM (Operation and Maintenance Manual) in a protective case on the attachment, where it can be conveniently accessed.

-

Included Tools

Attachment mounted tools included to provide quick and easy change out of bits when needed.

-

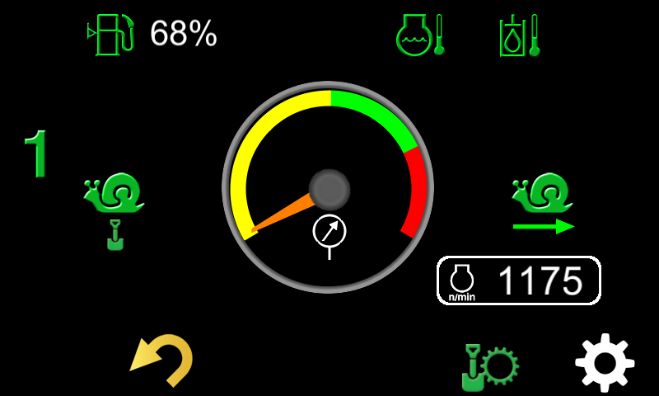

Smart Creep

Smart Creep is a dynamic drive control system that works in conjunction with the initial creep speed setting. Smart Creep senses load on the attachment being operated, and can automatically adjusts drive command to keep the attachment running at the most productive speed.

-

Optional Guide Bar

Optional guide bar allows operator to position wheel saw for better visibility of cut path, allowing for a straighter cut.

-

Water Kit Ready

Ports are strategically located to equip the saw with a water sprinkler kit along hood, which allows for significant dust reduction.

Specifications

Units for specifications

General

| Maximum Cutting Depth | 17.7 in 450 mm |

|---|---|

| Wheel Width | 3.1 in 80 mm |

| Weight | 2482.4 lb 1126 kg |

| Overall Width | 65.2 in 1655 mm |

| Overall Height | 57.3 in 1455 mm |

| Length | 85.2 in 2165 mm |

| Required Hydraulics | High Flow XPS |

| Optimal Hydraulic Flow | 98-125 L/min (26-33 gpm) |

| Optimal Hydraulic Pressure | 230-280 bar (3300-4000 psi) |

| Motor Displacement | 85.7 in³/rev 1404 cm³/rev |

| Wheel Torque at Maximum Pressure | 4605.3 lb/ft 6244 N·m |

| Wheel Speed at Maximum Flow | 89 RPM |

| Bit Speed at Maximum Flow | 1145 ft/min 349 m/min |

| Conical Bits - Per Wheel | 64 |

| Standard Bit Type | Concrete |

| Optional Bit Type | All Purpose |

| Side Shift Travel | 21.7 in 550 mm |

| Trench Cleaning Device | No |

| Drive Method | Direct Drive |

| Interface Type | Skid Steer Coupler |

Videos

-

Cat® Wheel Saw at Work -

Cat® Wheel Saw Overview -

Cat® Wheel Saw Operator Tips -

Cat® SW480 Wheel Saw and 272D3 XE Skid Steer Loader Customer Story -

Cat® Smart Creep Technology