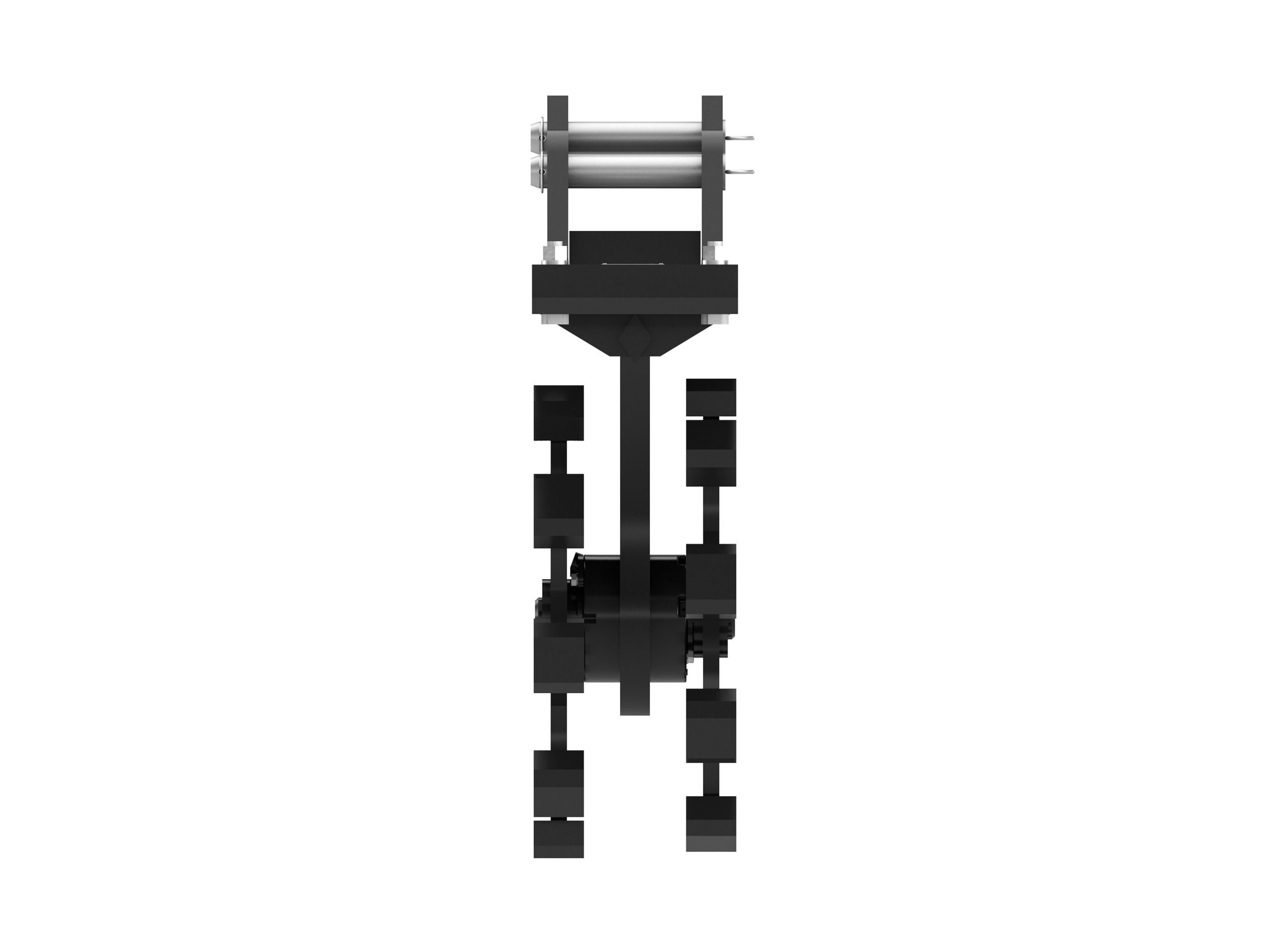

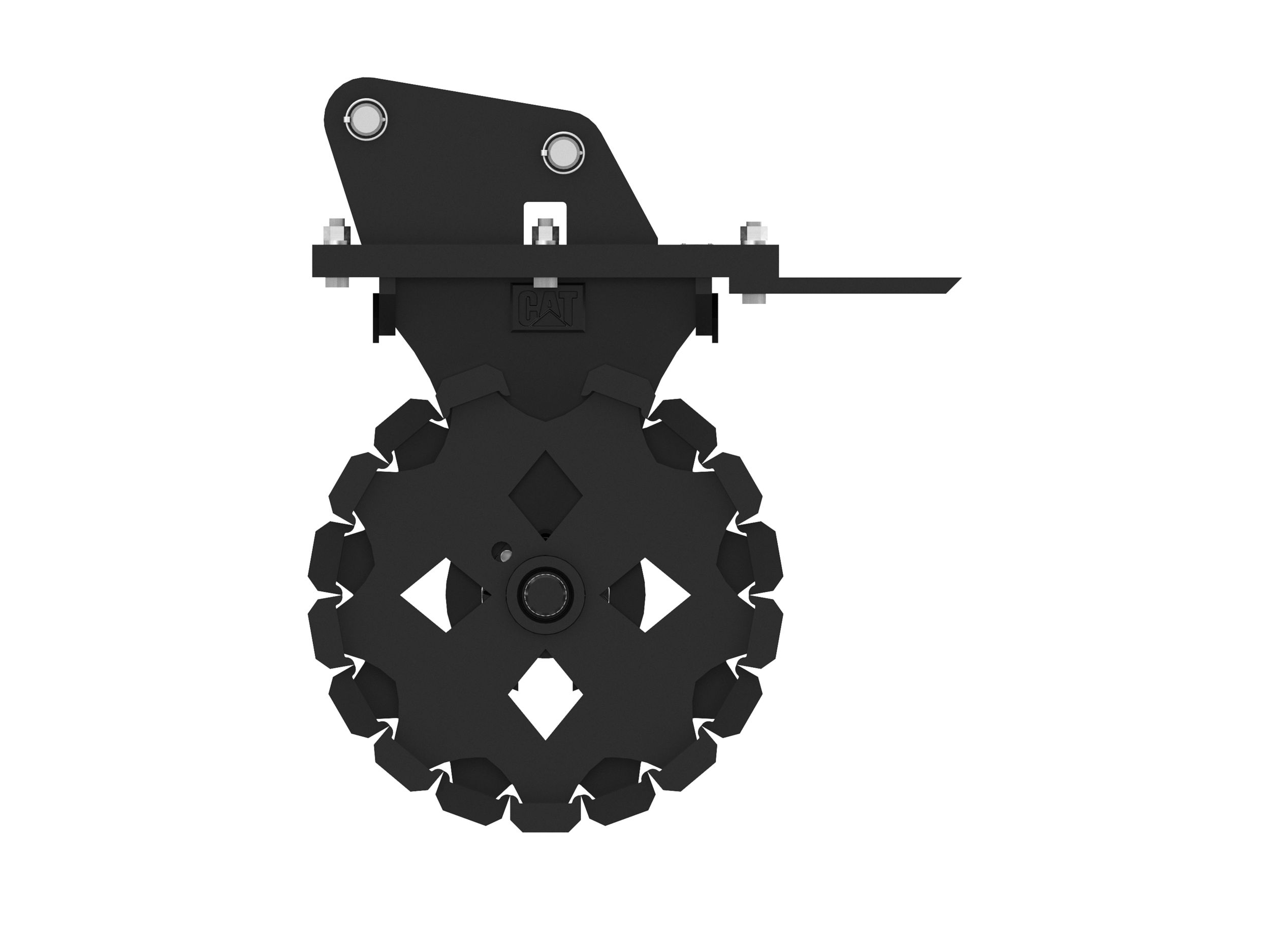

305 mm (12 in) Pin On Compaction Wheel For 7-8 Ton Mini Excavators

- Compaction Width

- 12 in

- Number of Wheels

- 2

- Machine Class

- 7-8 Ton Mini Excavators

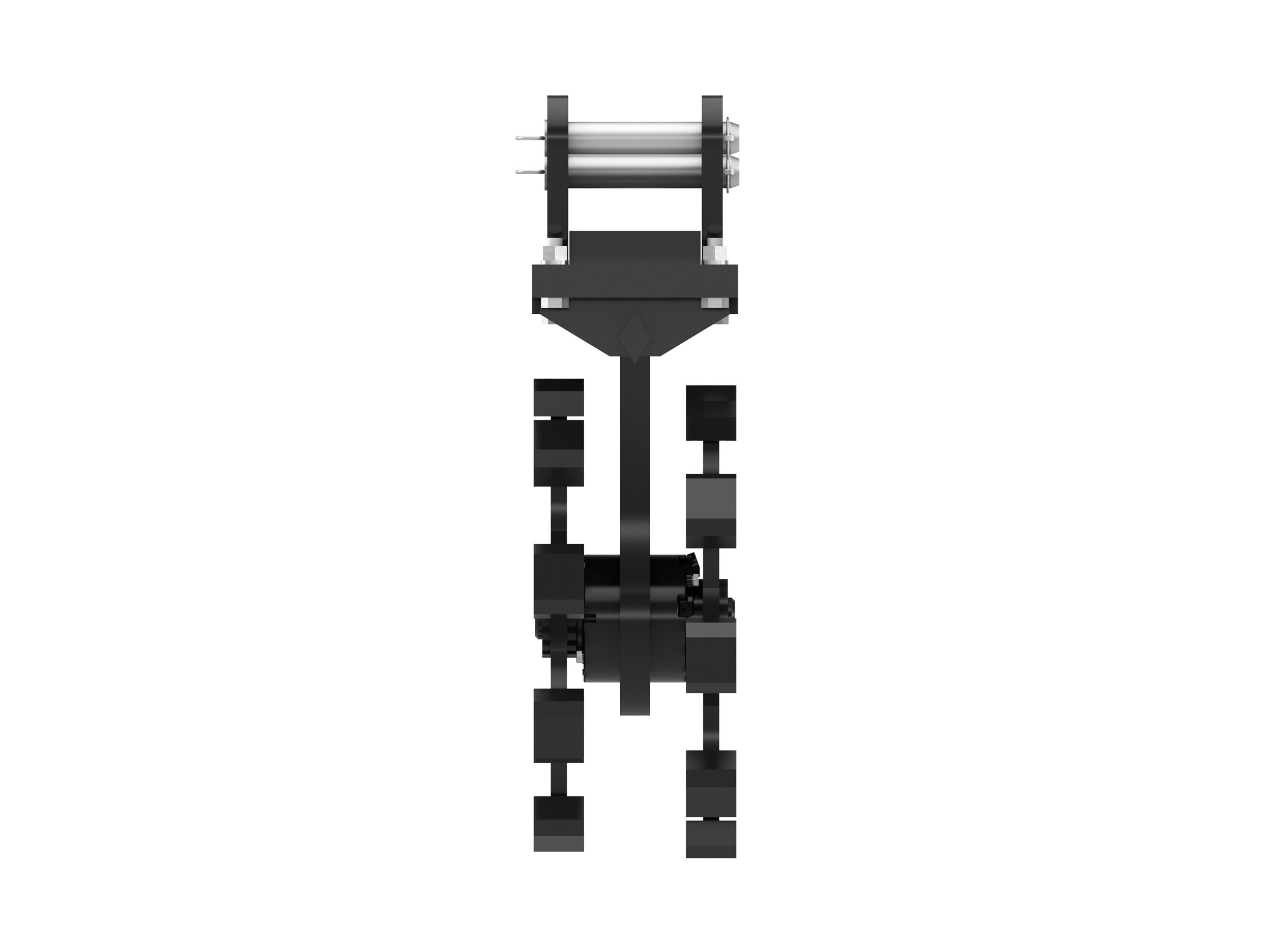

Cat® Compaction Wheels for Backhoe Loaders and Mini Excavators provide a low cost option for trench compaction. The wheels feature tapered roller bearings and tampered foot design with static pad rollers, to allow for smooth operation and achieving a high level of compaction. Six to ten passes are usually adequate to achieve compaction in normal soil conditions, dependent on the required compaction levels.

Features

-

Application

Used to compact trenches and easily backfill.

-

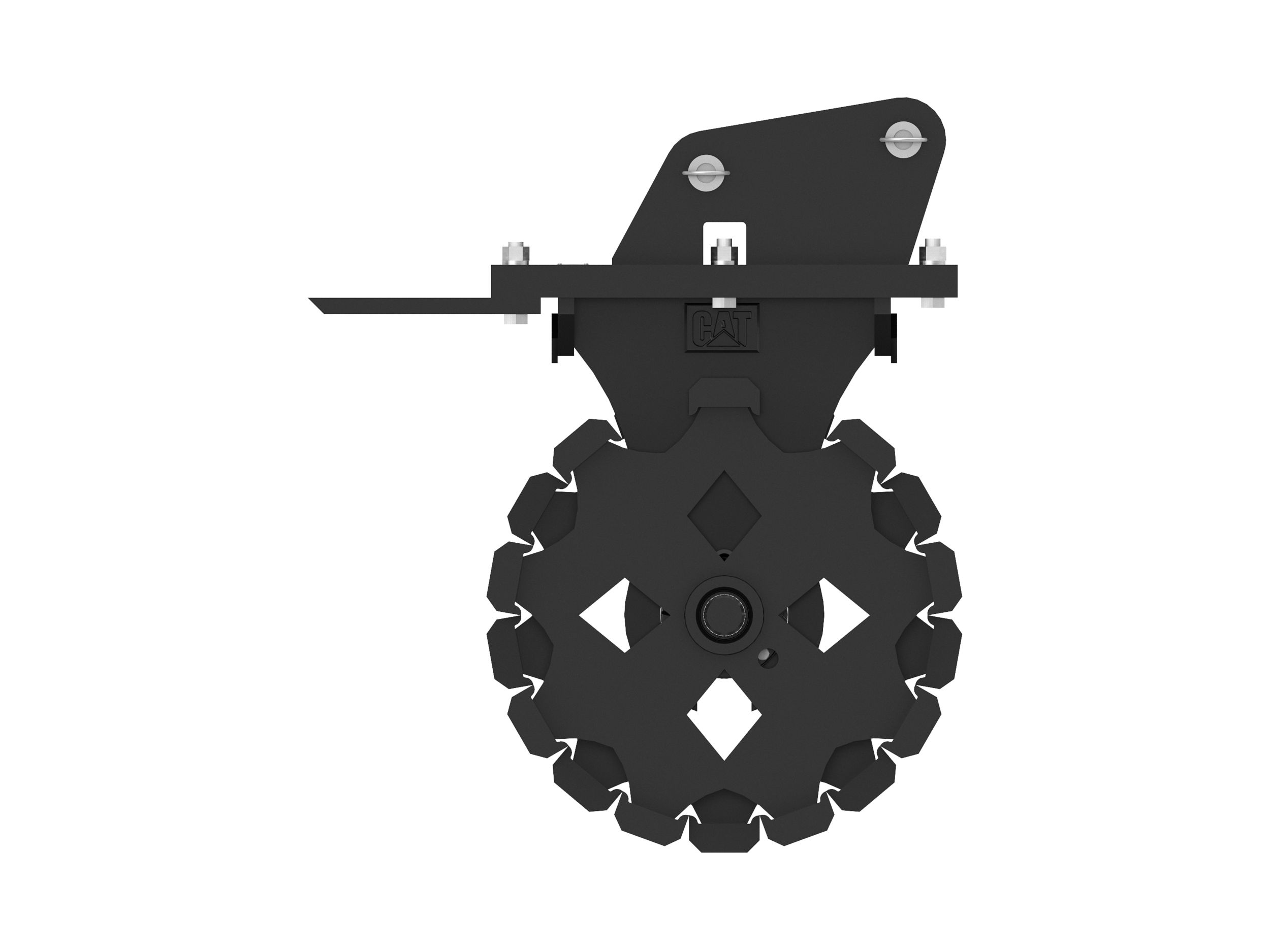

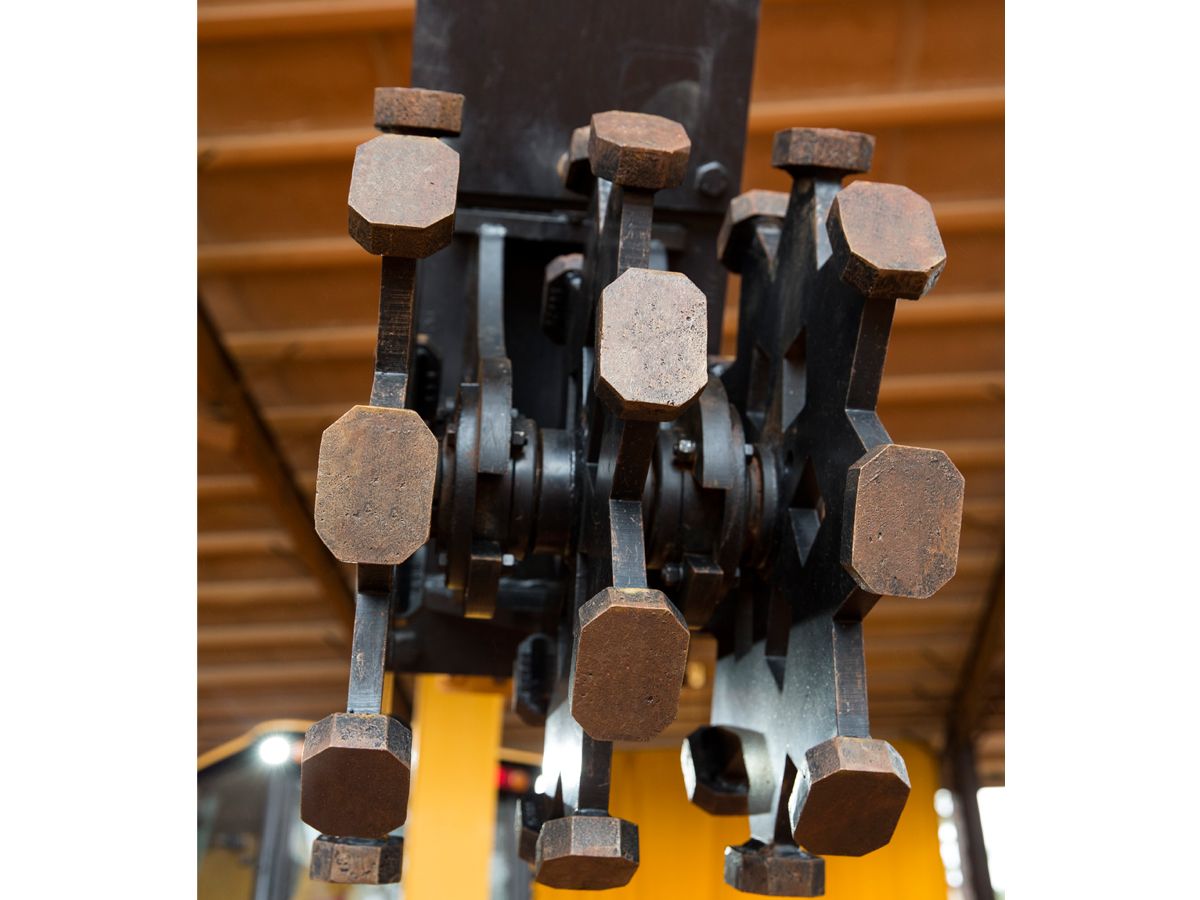

Tamper Foot Design with Static Pad Rollers

Static pad rollers are best suitable for compacting cohesive soils and achieving a higher degree of compaction.

-

Tapered Roller Bearing

Tapered roller bearing provides smooth wheel operation and appropriate tool balance.

-

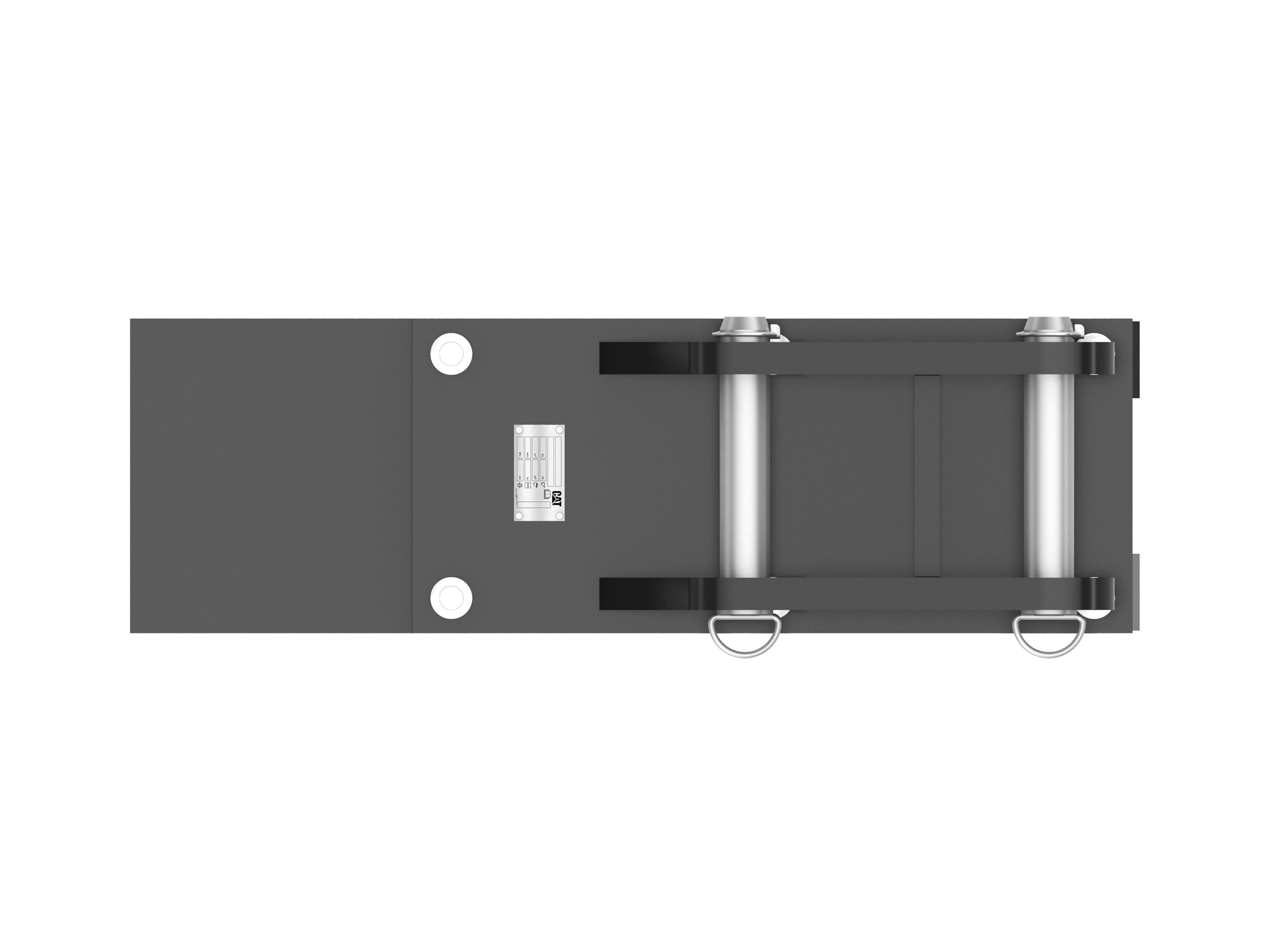

Standard Backfill Plate

Backfill plate bolts onto main tool interface to be used in collaboration with wheel, to create smooth trench bottom.

-

Open Rim Design

Open rim design allows wheel to penetrate through the lift of trench fill and compact soil from the bottom up, rather than the top down.

Specifications

Units for specifications

General

| Compaction Width | 12 in 306 mm |

|---|---|

| Number of Wheels | 2 |

| Machine Class | 7-8 Ton Mini Excavators |

| Number of Pads | 18 |

| Weight | 914.9 lb 415 kg |

| Overall Length | 39.3 in 998 mm |

| Overall Height | 45.4 in 1152 mm |

| Overall Width | 13.3 in 338 mm |

| Interface Type | Pin On |

Videos

-

Cat® Compaction Wheels at Work -

Cat® Compaction Wheels Overview -

An Attachment for Every Job - Cat® Work Tool Attachments