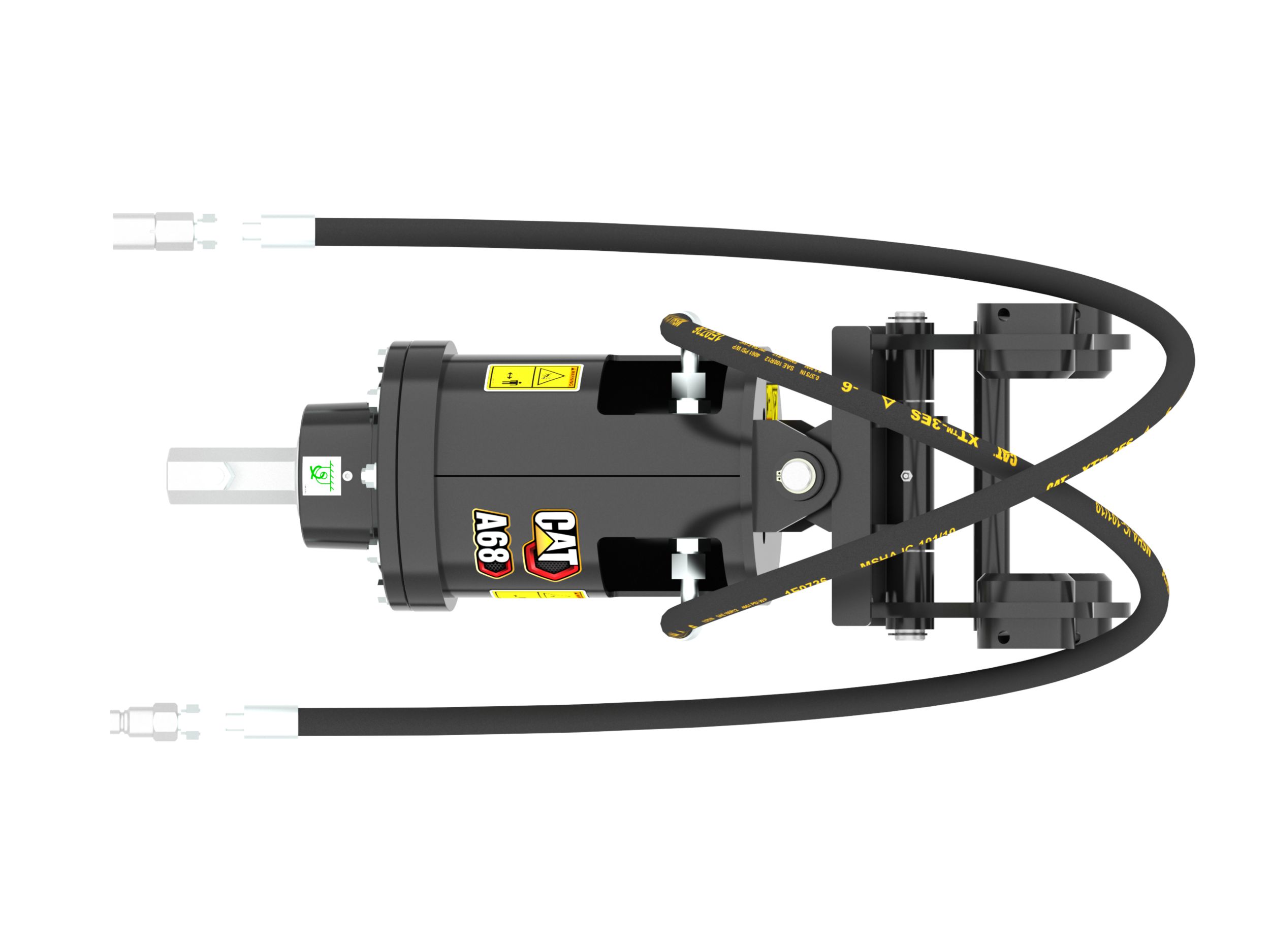

A68 Auger For 5 Ton Mini Excavators

- Drive Shaft Torque at Maximum Pressure

- 5034.6 lb/ft

- Drive Method

- Gerotor Motor - Double Planetary Reduction

- Mounting Bracket Design

- 8 Ton Mini Excavator Pin On

Cat® Augers are used for drilling holes for footings, fencing, signs, trees and shrubs in construction, agricultural, and landscaping applications. They are designed with the right amount of speed and torque for maximum productivity in a broad range of soil types.

Features

-

Application

Cat® Augers are used to drill holes for footings, fencing, sign posts, trees and shrubs in construction, agricultural and landscaping applications.

-

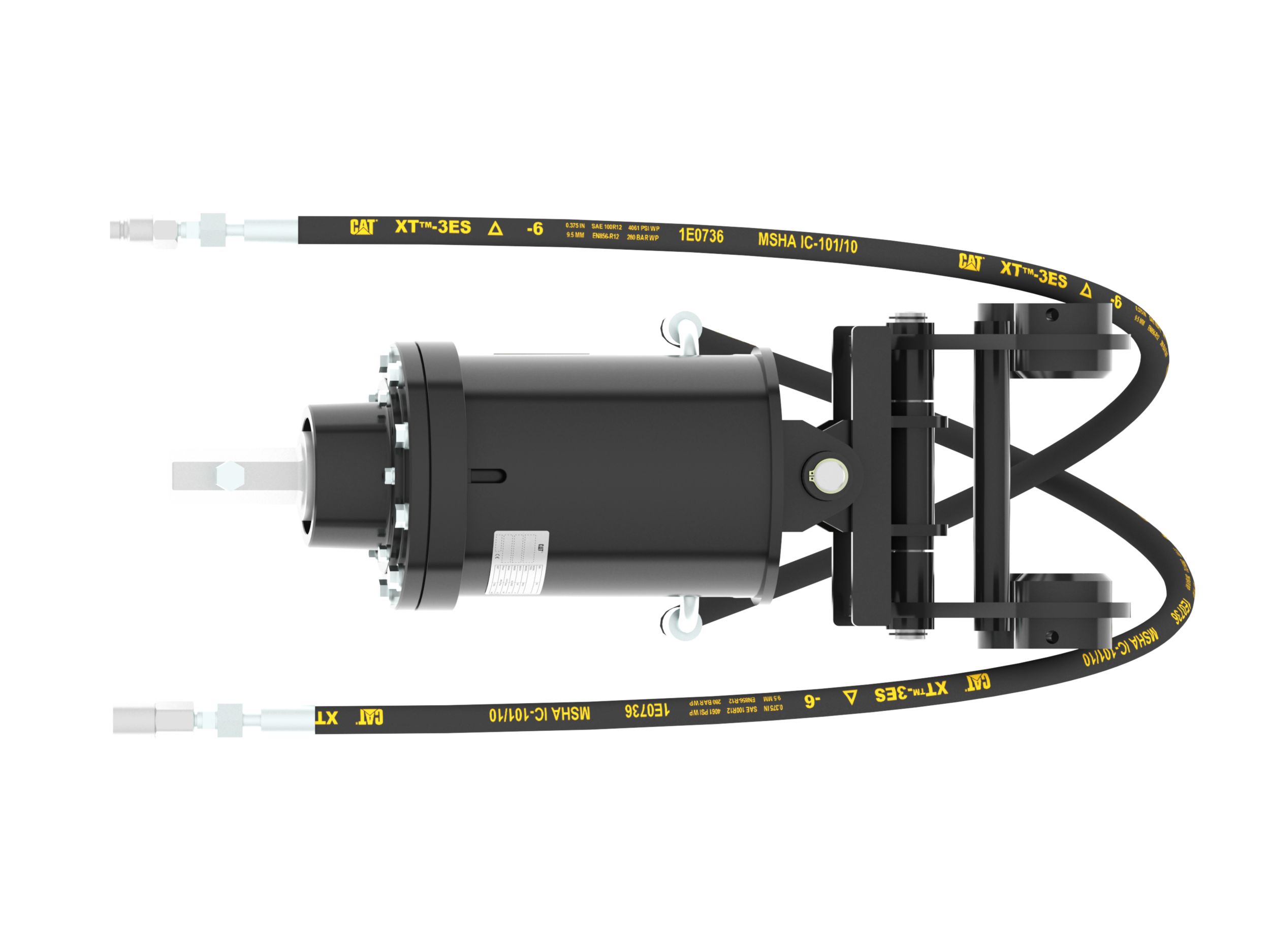

Multiple Drive Systems

Three different drive systems, all designed with the right amount of speed and torque for working in a broad range of soil types.

- A23 feature a variable speed, bi-directional, gerotor style hydraulic motor that generates optimal bit speed and output torque for light to moderate duty work.

- A41 features a variable speed, bi-directional, single reduction planetary drive gerotor style hydraulic motor mounted to a planetary gear box for optimal bit speed and output torque for moderate to heavy-duty applications.

- A68 features variable speed, bi-directional, double reduction planetary drive hydraulic gear motor mounted to a planetary gear box for optimal bit speed and output torque for moderate to heavy-duty, high performance drilling requirements.

-

Rugged Bits for Every Application

Rugged bits are adaptable to a number of projects. Standard bits, tree bits, industrial bits and standard rock drill head bits (bolt-on) are offered to cover a wide variety of applications and ground conditions.

-

Bit Extensions and Adapters

Various extensions allow for digging deeper and adapting to round or hex shaft bit designs. Retention pin reduces time to auger flight changes.

-

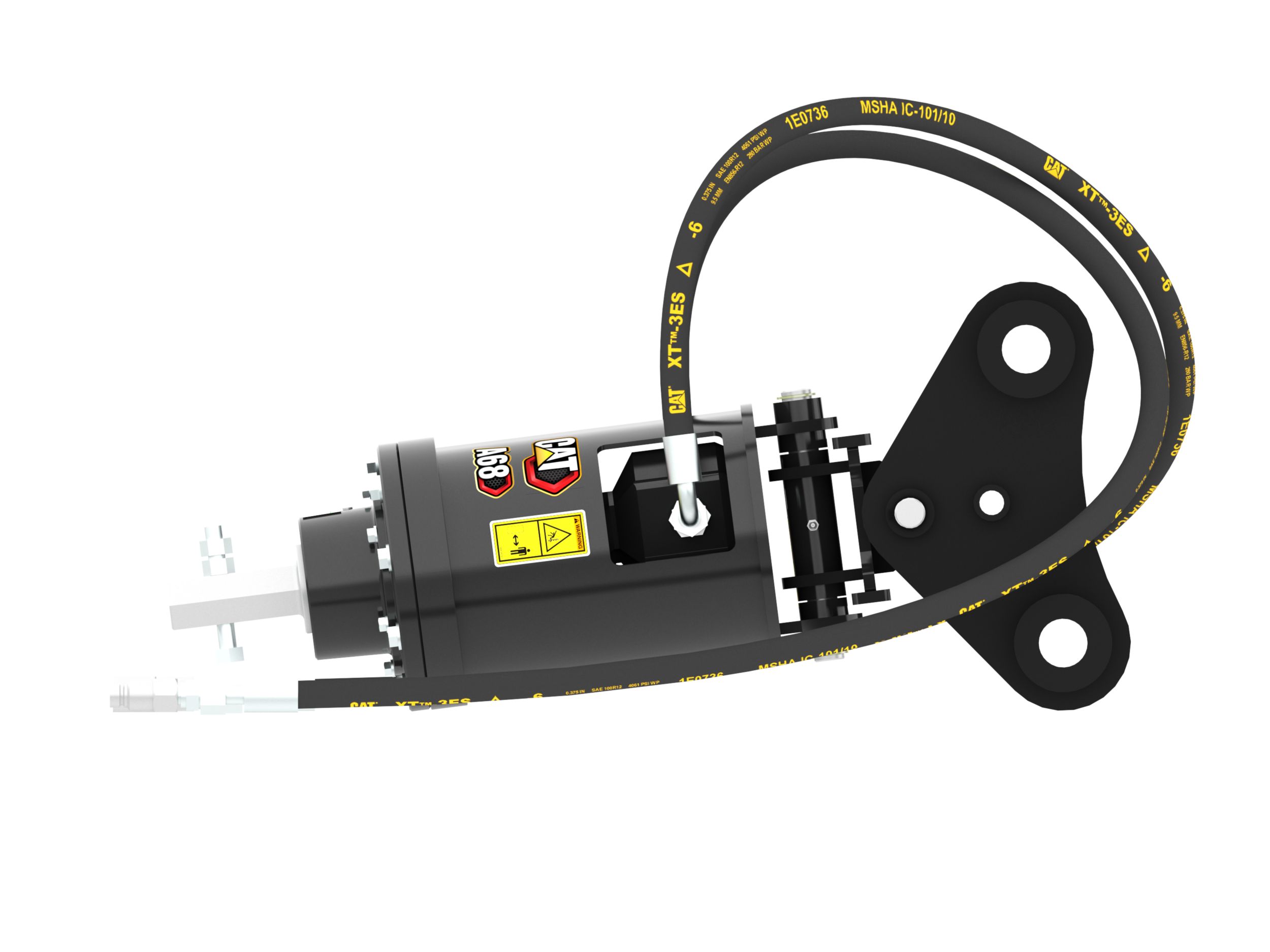

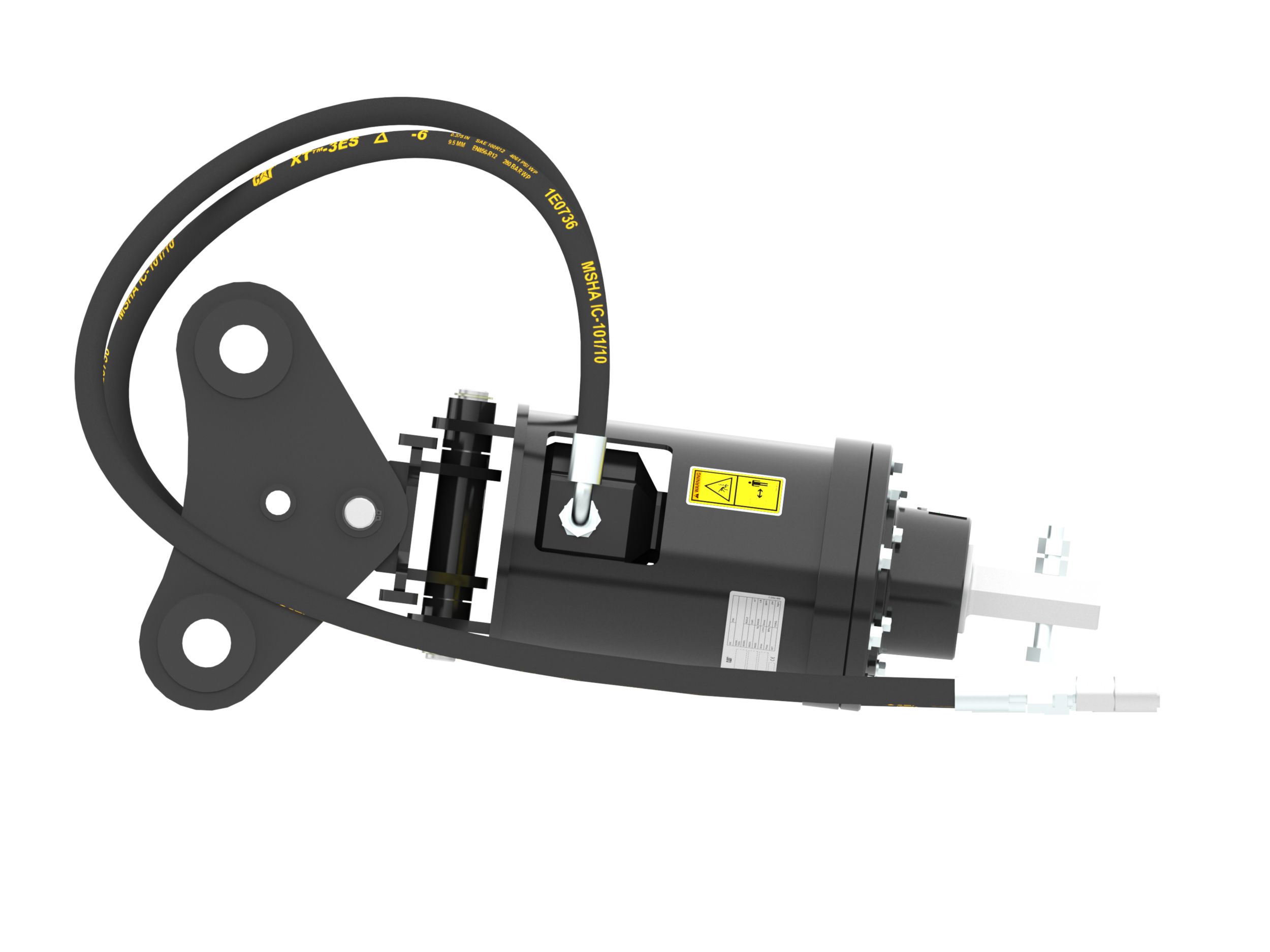

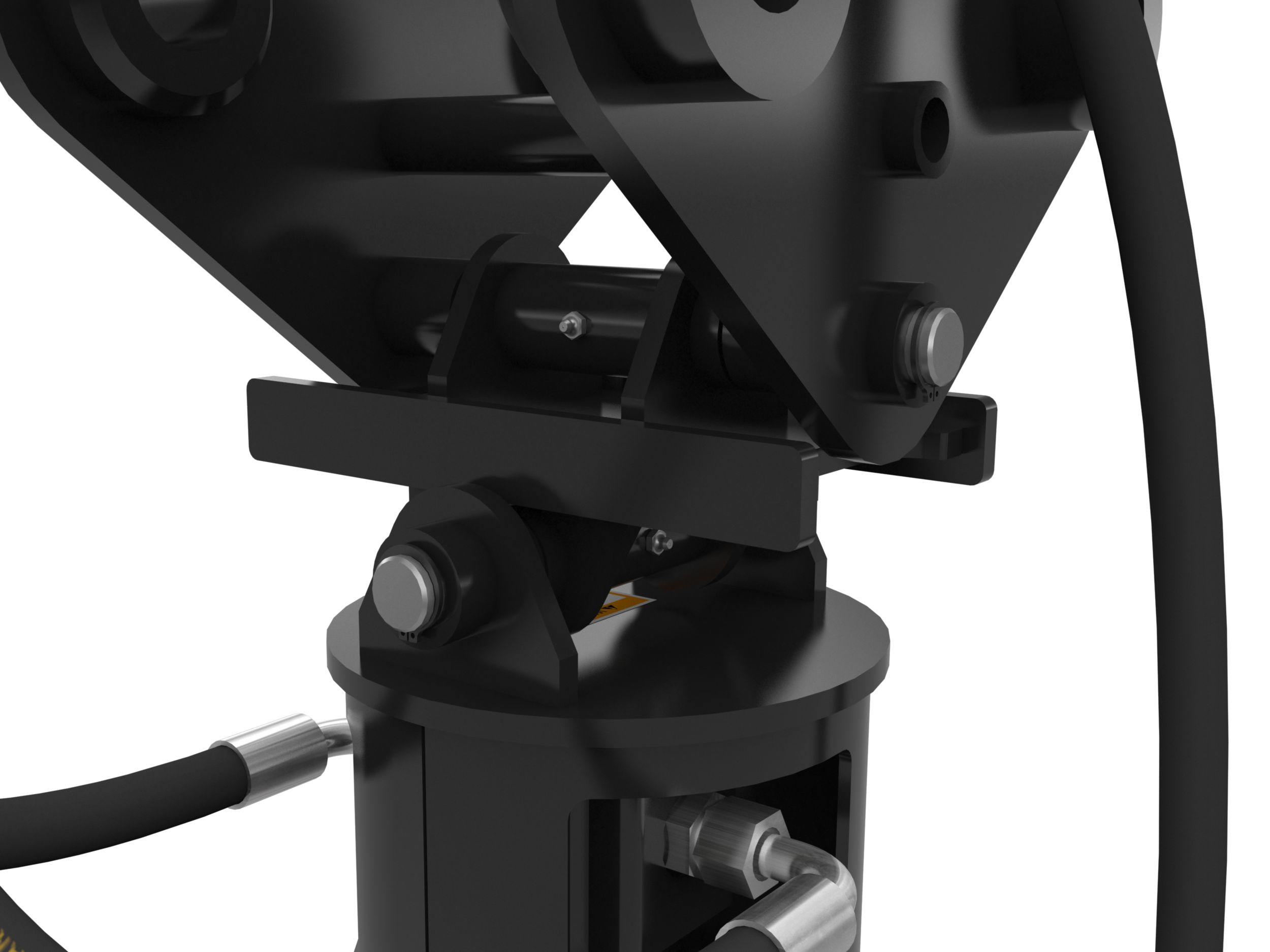

Articulated Joint

Articulated joint ensures auger hangs straight, independent of machine positioning.

-

Mechanical Swing Stops

Mechanical swing stops protect from auger over swing.

Specifications

Units for specifications

General

| Drive Shaft Torque at Maximum Pressure | 5034.6 lb/ft 6826 N·m |

|---|---|

| Drive Method | Gerotor Motor - Double Planetary Reduction |

| Mounting Bracket Design | 8 Ton Mini Excavator Pin On |

| Required Hydraulics | High Flow XPS |

| Optimal Hydraulic Flow | 95-130 L/min (25-34 gpm) |

| Optimal Hydraulic Pressure | 207-290 bar (3002-4206 psi) |

| Overall Width - With Bracket | 13.9 in 354 mm |

| Overall Length - With Bracket | 17.5 in 445 mm |

| Overall Height | 36.1 in 916 mm |

| Housing Diameter | 11 in 280 mm |

| Swing Range (fore/aft) | 60 degrees |

| Swing Range (L/R) | 76 degrees |

| Weight | 324.1 lb 147 kg |

| Motor Displacement | 2.67 in³ 44 cm³ |

| Bit Speed at Maximum Flow | 81 rpm |

| Hex Output Shaft Size | 2 in 51 mm |

Optional Equipment

OTHER ATTACHMENTS

- Rear step, standard

Videos

-

Cat® Auger Attachment at Work -

Cat® Auger Attachment Overview -

An Attachment for Every Job - Cat® Work Tool Attachments