The AP600 is a mid to high production wheel paver that offers versatility for highways, rural roads, streets and other mid-sized projects. It can be equipped with either a front-mount extender screed or a rear-mount extender screed.

Features

-

High Return on Investment

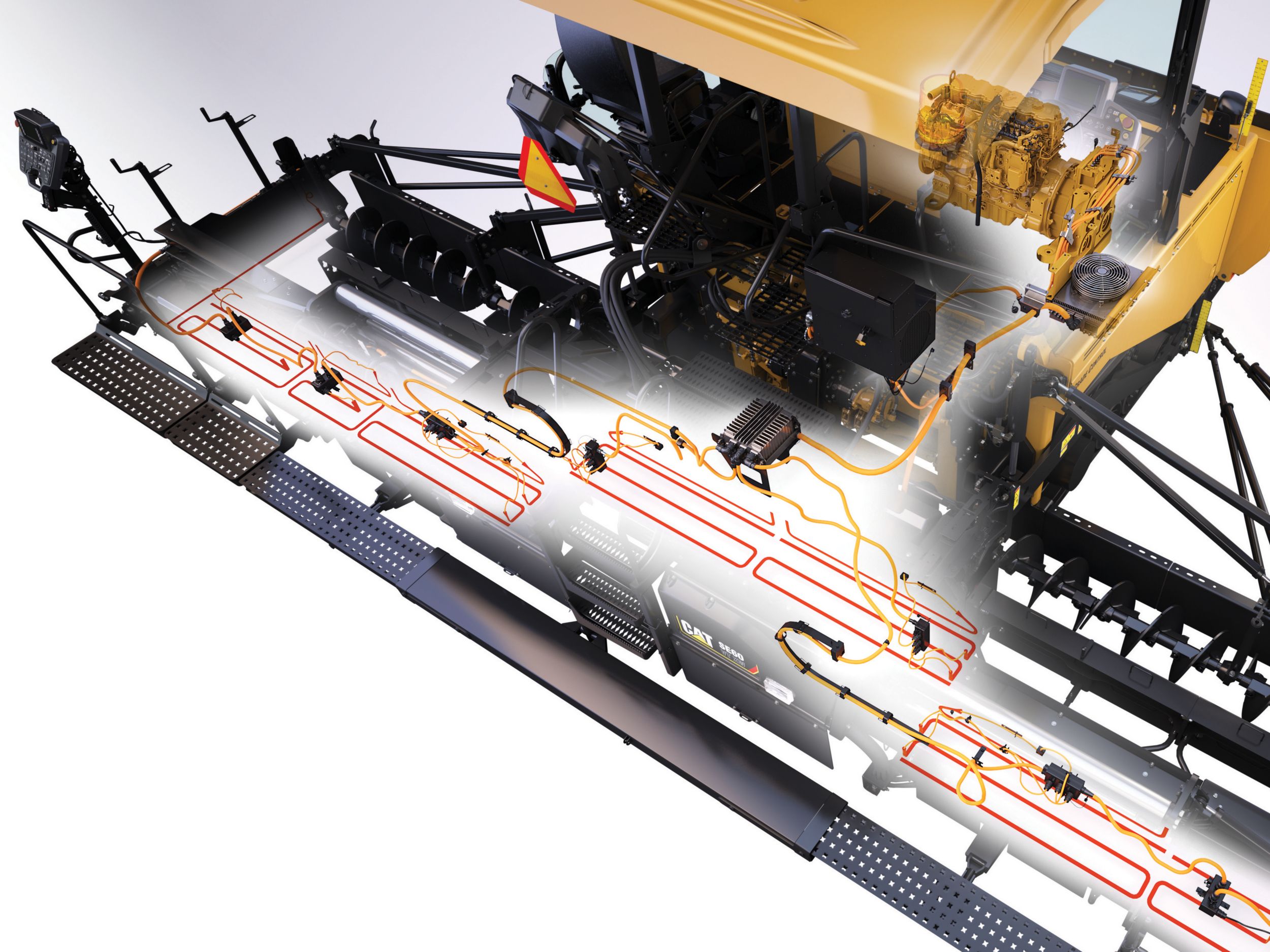

- Exclusive 70 kW integrated generator delivers fast, reliable screed heating and is designed for long life by the same team that developed the D7E electric drive dozer

- Fast heating screed leads to more daily production, heating time in as little as 15 minutes

- Excellent turning capability, fast travel leads to increased production

• Exclusive air flow design improves operating conditions for the crew and keeps components cooler for lasting durability

-

Technology That Works For You

- Pave Start Assistant saves set-up profiles for repeatable use on future job sites including Grade Control settings, speed, paving width, paving depth, slope, crown, height, and other set-up features

- A hopper level sensor (option) with temperature indication keeps the operator informed of material height and delivery temperatures, indicators are located in each tractor display

- Exclusive screed heating system monitors elements for failure conditions and helps eliminate unnecessary replacement

- Cat® Grade Control option is integrated into the tractor and screed displays for optimized operator efficiency

- Thermal mapping (option) utilizes an infra-red camera mounted on a fixed-position mast that captures the entire width of the asphalt surface behind the screed. An LCD display mounted near the screed console provides real-time visibility to the surface being paved

-

Quality Results, Higher Earnings

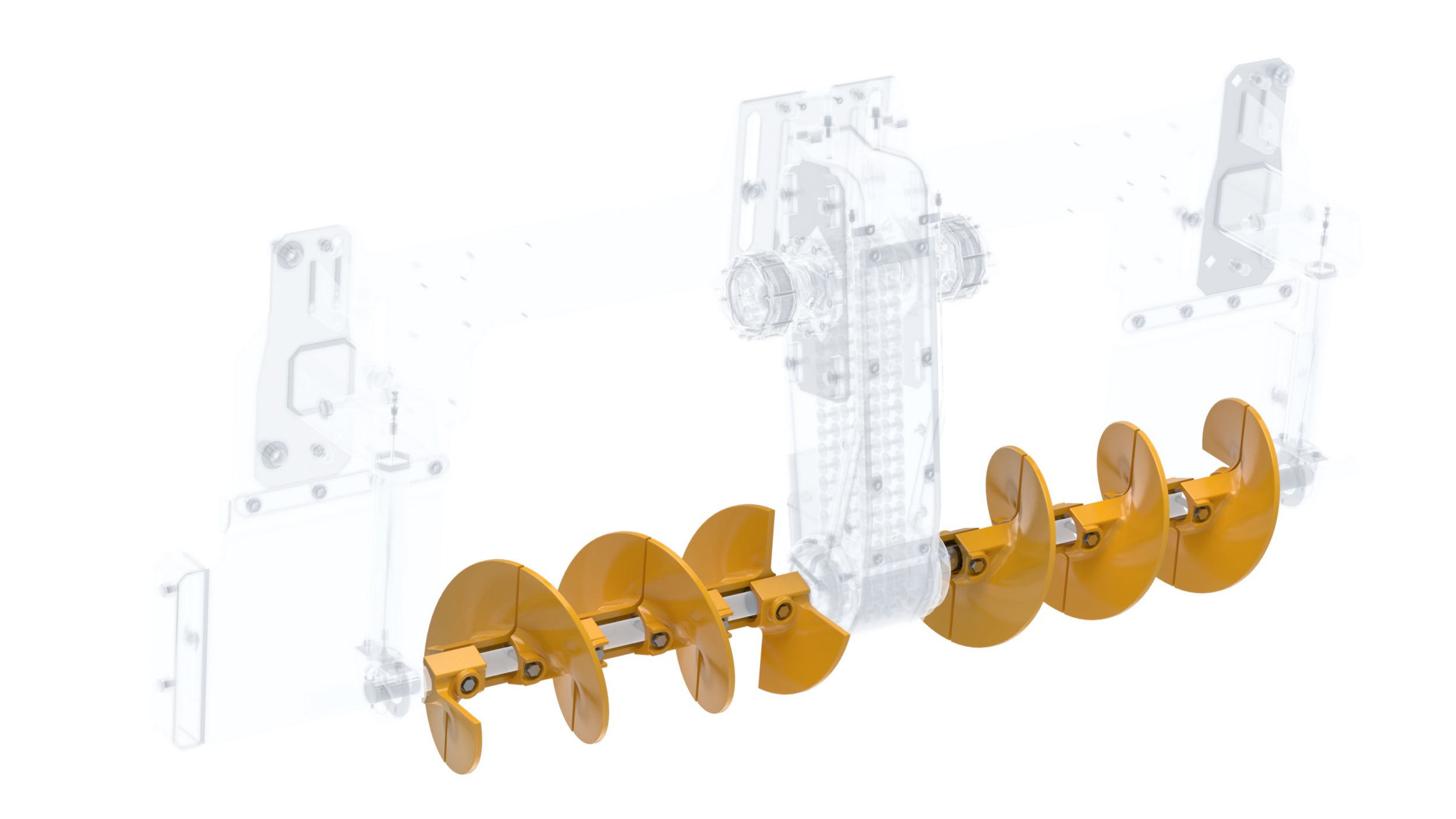

- Versatile screed designs deliver excellent ride, density, and mat texture while providing superior adjustment; available with front-mount extenders, or rear-mount extenders

- Tow-point utilizes exclusive linkage design for optimal screed flotation

- Exclusive 2-speed proportional control on the screed extenders

- Cat Grade Control or Basic Grade Control options available

-

Low Owning and Operating Costs

- Exclusive Eco-mode and Automatic Engine Speed Control, reduce fuel consumption and lower sound levels for better comfort and communication

- 4-pump feeder system is designed for high production in Eco-mode, leads to lower fuel consumption

- Million cycle switches provide reliability

- Conveyor bed plates and chain guards designed to minimize labor requirements and provide lower cost replacement

- Heating elements slide-out for easy replacement

- Machined screed frames simplify screed plate replacement

- Enhanced hopper flashing with increased memory and temperature resiliency for better performance during truck exchanges

-

More Comfort

- Ventilation system draws fumes from the auger chamber and redirects them away from the operator for a more comfortable working environment

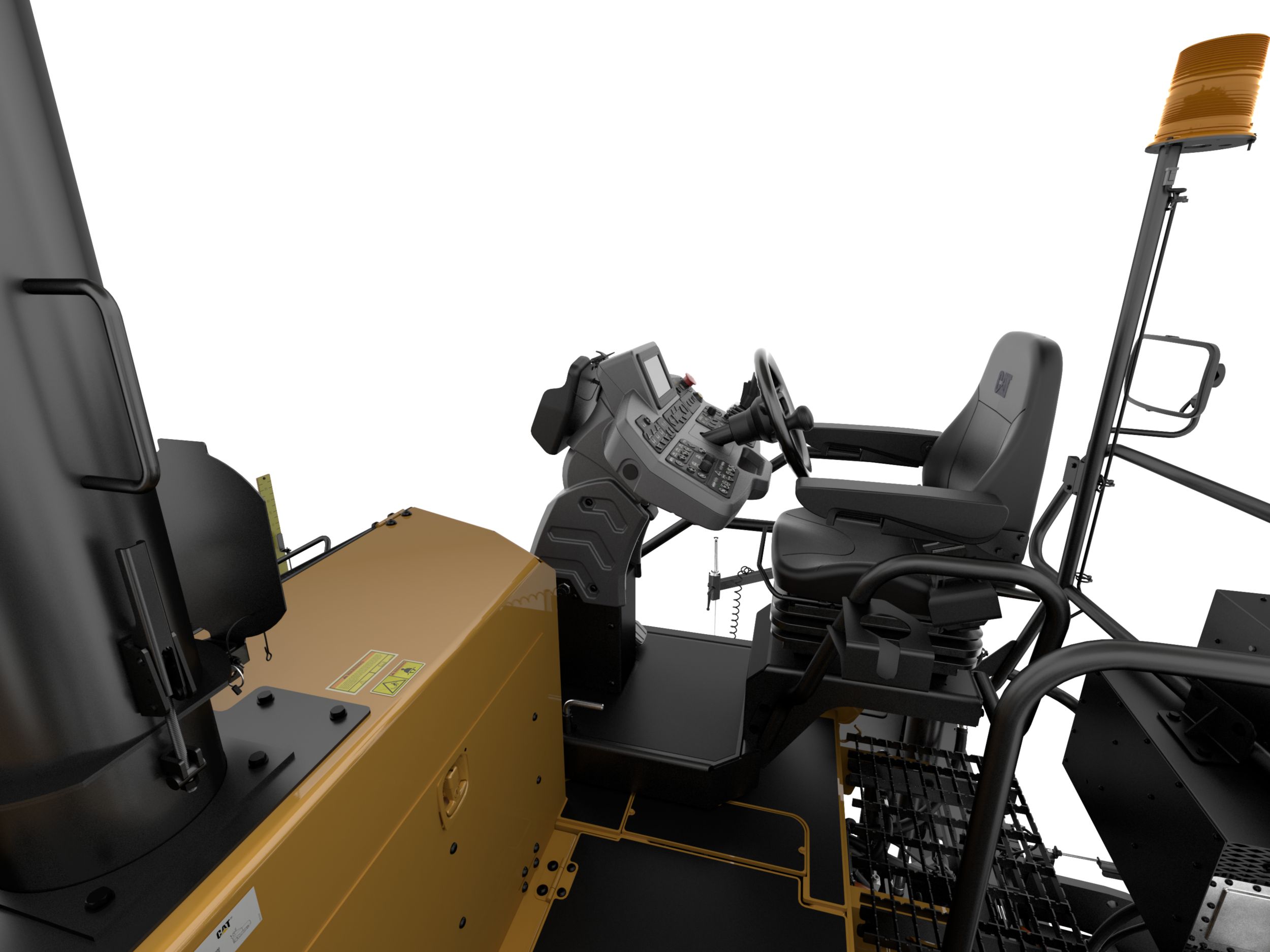

- Dual operating station provide back-up capability and complete control from either side of the machine, each station can swing-out beyond the frame for good all-around visibility

- Heated seat option, pneumatic suspension, multiple adjustments, and tilting consoles provide day-long comfort

- Eco-mode provides low sound levels that supports clear communication with the crew

- High visibility 76 mm (3″) seat belt helps with crew safety compliance

- USB port simplifies software updates

- Cup holders offer convenience

-

Easy Viewing Displays

- Touch-screen displays with adjustable brightness control enable operators to fine-tune performance in various lighting conditions

- Touch-screen access simplifies activation of the generator and auxiliary power, while also providing easy adjustments to screed plate heating temperatures, vibratory speeds, Cat Grade Control (option), and stored operator preferences

- Operating displays can be tailored to specific language requirements with multiple options available

-

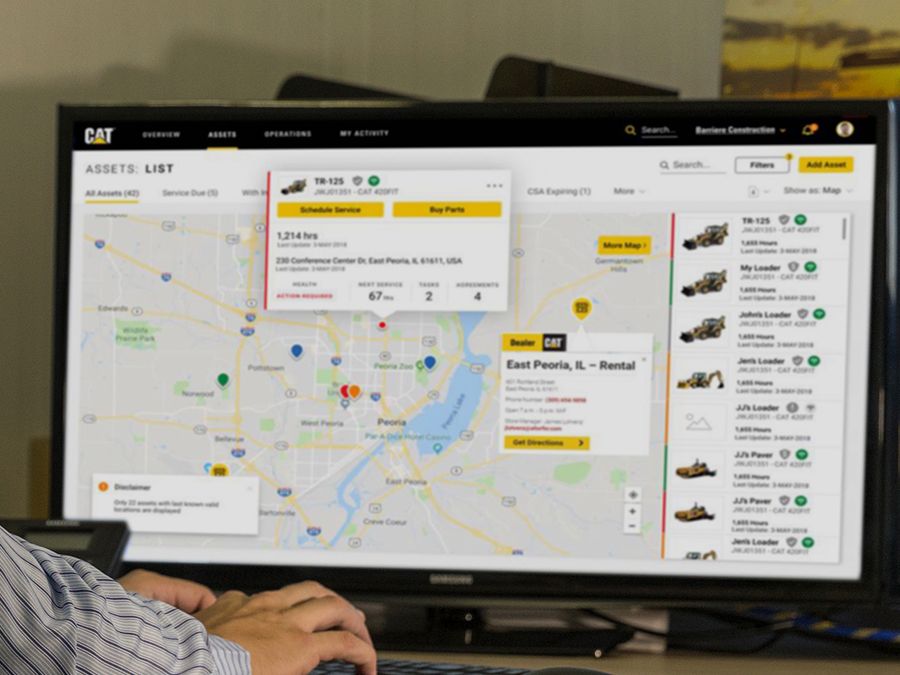

Product Link™ Elite

- Make timely, fact-based decisions to maximize efficiency, improve productivity, and lower owning and operating costs

- Easily track location, machine hours, fuel usage, and idle time

- Diagnostic codes are made available through online web applications

-

Service and Repair Kits

- Paver and screed service and repair kits include the parts necessary to complete specific repairs

- Cat genuine parts are manufactured to precise specifications and designed for optimal performance and maximum uptime

- Repair kits are identified by a single part number to make ordering easy

- Select kits are available to be packaged as a kit by the dealer for over the-counter purchases or through the dealer service shop

Specifications

Units for specifications

Dimensions

| Paving Range with SE47 FM | 2.44 m - 6.2 m (8' - 20' 6") |

|---|---|

| Paving Range with SE50 V | 2.55 m - 6.5 m (8' 4" - 21' 4") |

| Paving Range with SE60 FM | 3.0 m - 7.8 m (10' - 25' 6") |

| Paving Range with SE60 V | 3.0 m - 7.5 m (9' 10" - 24' 6") |

| Operating Length | 21.75 ft 6.6 m |

| Operating Width | 10.8 ft 3.3 m |

| Overall Height | 12.5 ft 3.8 m |

| Transport Length | 20.9 ft 6.4 m |

| Transport Width | 9.8 ft 2.9 m |

| Transport Height | 9.9 ft 3.3 m |

Engine

| Gross Power | 173 hp 129 kW |

|---|---|

| Engine Model | Cat C4.4 |

Operating Specifications

| Maximum Travel Speed | 10 mile/h 16 km/h |

|---|---|

| Maximum Paving Speed | 250 ft/min 76 m/min |

| Inside Turn Radius | 4.5 ft 1.5 m |

| Maximum Throughput Capacity | 1433 ton(US)/h 1300 tonnes/hr |

Weights

| Operating weight with SE47 FM | 36,716 lb 16659 kg |

|---|---|

| Operating weight with SE50 V | 37,754 lb 17125 kg |

| Operating weight with SE60 FM | 38,316 lb 17380 kg |

| Operating weight with SE60 V | 38,056 lb 17262 kg |

| Shipping Weight - Paver Only | 29,391 lb 13556 kg |

Service Refill Capacities

| Fuel Tank Capacity | 73 gal (US) 278 l |

|---|---|

| DEF Tank | 5 gal (US) 19.1 l |

| Cooling System - Total | 8 gal (US) 31 l |

| Hydraulic Oil Tank | 58 gal (US) 219 l |

| Washdown Spray Tank | 7.9 gal (US) 30 l |

Standard Equipment

Operating Environment

- Dual operating stations

- Steering guide

- Ventilation System

Technology

- Product Link™ Elite 641_cellular

Powertrain

- Automatic engine speed control

- Cat C4.4 Engine

- Variable speed cooling fan

- Eco-mode

- Extended life hydraulic oil

Electrical system

- 1000 CCA batteries

- 100 amp alternator

- 12-volt power receptacle

- Cat Electronic Technician

- Automotive type fuse system

- 70 kW generator

- Machine security system

Material Delivery

- Contact-type material feed sensors

- Adjustable push-roller

Service and Maintenance

- Extended-life coolant

- Engine coolant heater

- Remote access drains

- Scheduled Oil sampling ports

- Sight gauges

Safety

- Back-up alarm

- Horn

- Working lights

- Mirror package

- Vandal covers

Optional Equipment

Operating Environment

- Air-ride seat

- Hard top canopy

- Deceleration pedal

- Heated seats

- Side shields

- Towpoint indicator (2nd)

- Umbrella

- Screen visor

- Windshield

- Windshield

Technology

- Cat Grade Control

- Hopper level and material height sensor

- Pave start assistant

- Product Link™ Elite 631_satellite

- Thermal mapping

Powertrain

- All wheel drive

- Ballast_front weights

- Front wheel assist

- Radial drive tires

- Sand rib drive tires

Electrical System

- Auxiliary power panel_6.6 kW

Material Delivery

- Auger extension

- Leveling devices

- Mainframe extensions_manual

- Mainframe extensions_power

- Sonic feed sensors

- Power folding front apron

- Truck hitch

- Washdown pump and reel

- Washdown tank

- Wide width paving packages

Service and Maintenance

- Uptime kits

- Service repair kits

Grade References

- Sonic Averaging Beam

- Rigid Ski, 9.15 m (30') and 12.2 m (40')

Screed Choices

- SE47 FM Screed

- SE50 V Screed

- SE60 V Screed

- SE60 FM Screed

Videos

-

Paving by the Numbers -

Cat Grade Control Setup