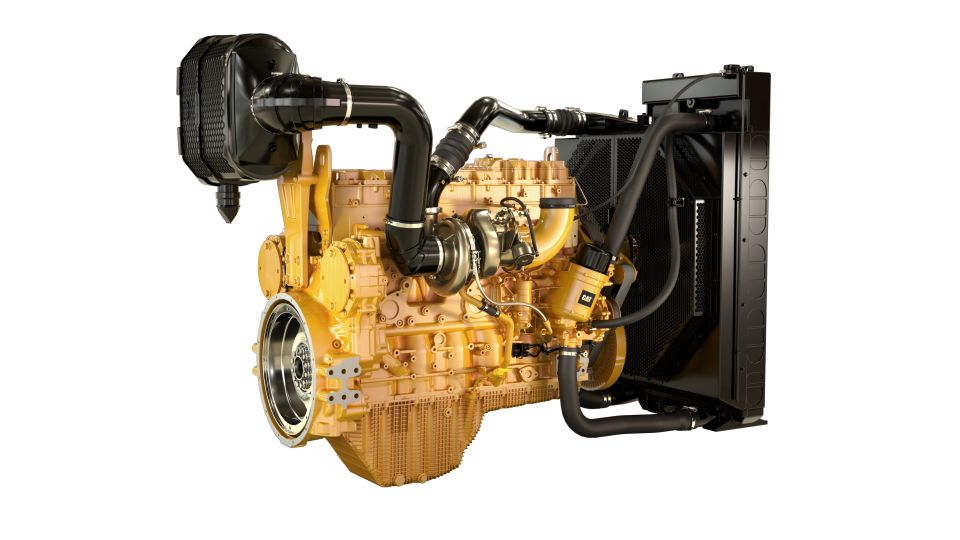

The Cat® C13D IPU configuration not only provides the flexibility and options found on a standard industrial engine, but also comes fitted with an integrated cooling system, an on-engine fuel filtration module, as well as full wire harnessing leading to an engine-mounted ECM. Meeting UN ECE R96 Stage IIIA, Brazil Mar-1, and other equivalent emission standards, the IPU allows for easier and faster installation, allowing the customer to spend more time doing the work that matters.

Features

-

Full Packaged Installation

-

Reliable, Quiet and Durable Power

-

Ideal Applications

-

Cat Dealer Support

-

Safety

Specifications

Units for specifications

Power Rating

| Maximum Power | 690 hp 515 kW |

|---|---|

| Maximum Torque | 2360 lb-ft @ 1300 rpm 3200 Nm @ 1300 rpm |

| Rated Speed | 1800-2100 rpm |

| Minimum Power | 456 hp 340 kW |

Emission Standards

| Emissions | UN ECE R96 Stage IIIA, Brazil Mar-1, Unregulated |

|---|

General

| Engine Configuration | In-Line 6 |

|---|---|

| Bore | 5.1 in 130 mm |

| Stroke | 6.4 in 162 mm |

| Displacement | 787.2 in³ 12.9 l |

| Compression Ratio | 16.5:1 |

| Aspiration | Turbocharged-Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

Engine Dimensions*

| Length | 89 in 2249 mm |

|---|---|

| Width | 46 in 1160 mm |

| Height | 65 in 1641 mm |

| Dry Weight | 3856 lb 1749 kg |

Standard Equipment

Air Inlet System

- Wastegated turbocharger

- Air-to-Air Aftercooled

- Front or rear exhaust configurations available

Control System

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Integrated Electronic Control Unit (ECU)

- Remote fan control

Cooling System

- Fluids module, which includes: water pump, oil cooler, top-service cartridge oil filter (optional), dual coolant thermostats, and single oil thermostat

- Centrifugal water pump

- Guidance on cooling system design available through your dealer to ensure equipment reliability

- Remote oil filter variant of the fluids module available

Flywheel and Flywheel Housing

- Multiple Flywheel Housing configurations, featuring a basic, standard and heavy duty PTO setup

- Standard SAE No. 1 flywheel housing with SAE No. 14 or 140 flywheels

Fuel System

- Common rail direct injection fuel system with zero-static leak injectors

- Fuel module, which includes: primary and secondary cartridge filters, and a manual or electric priming pump

- Remote fuel module available

- Fuel manifold which allows for outboard or rearward fuel return-to-tank plumbing, as well as coolant supply

- Oil-lubricated high pressure fuel and mechanical fuel transfer pump combination

Lube System

- No-service-needed passive open crankcase ventilation filtration system built into the valve cover

- No-mess service oil filter drainback feature built into fluids module

- Oil filler

- Oil level sensor

- Oil dipstick

- Gear-driven oil pump

- Choice of front, rear or center sumps

- Open crankcase ventilation system with fumes disposal

Power Take Off (PTO)

- Up to 5 additional power take-offs: 2 rear facing (SAE B, C, or D), 2 forward-facing (SAE A or SAE B), and an additional low-mount forward-facing (SAE B)

General

- Caterpillar yellow paint, with optional colors available on request

- Vibration damper

- Lifting eyes

Optional Equipment

Industrial Power Unit

- Factory-installed cooling pack which includes the radiator, the air-to-air aftercooler (ATAAC), coolant lines to and from the radiator, and air lines to and from the ATAAC.

- Factory-installed engine-mounted aftertreatment system, pre-connected exhaust air lines, and air cleaners

- Factory-installed instrument / control panels embedded with telematics units