CVP28 Vibratory Plate Compactor

- Impulse Force

- 6294.65 lb

- Impact Frequency

- 2200 bpm

- Base Plate Width

- 17.7 in

Cat® Vibratory Plate Compactors are used for compacting soil, sand or gravel prior to pouring concrete or laying asphalt surfaces. They are also ideal for asphalt patch work. Their capabilities and lower investment and maintenance costs make them popular with pavers, general contractors and utility contractors in residential, commercial or industrial applications.

Features

-

Application

Used for compacting soil, sand or gravel prior to pouring concrete or laying asphalt surfaces. Also ideal for asphalt patch work.

-

Superior Compaction Force

These units produce high-power impulses at a rate of 2200 impacts per minute driving soil particles close together for solid, stable compactions.

-

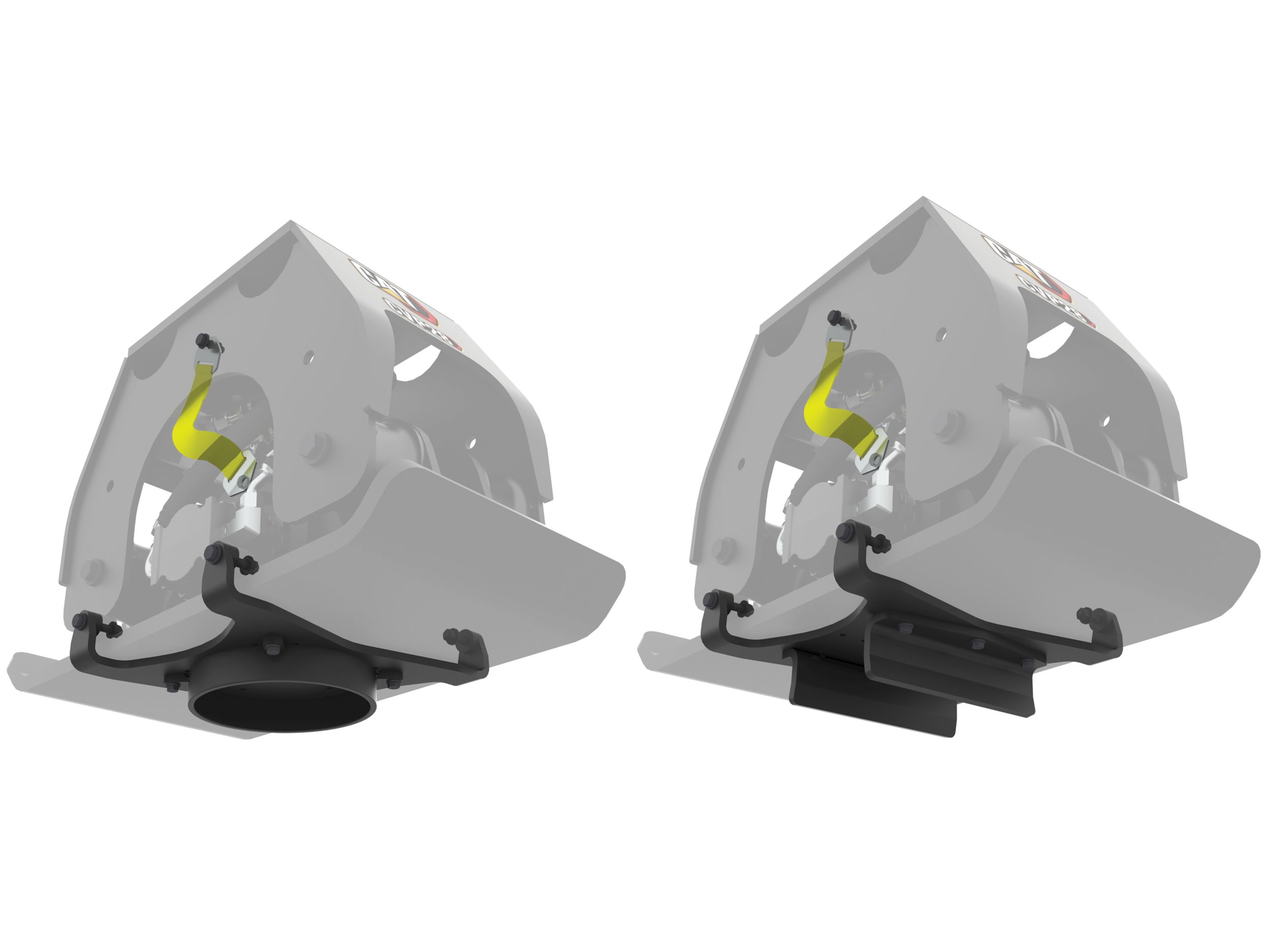

Common Mounting Solutions

Cat vibratory plate compactors share the same mounting solutions as the Cat B and H model Hammers. Mounting brackets are available for pin on, pin grabber, pin lock, CW, and S type connections.

-

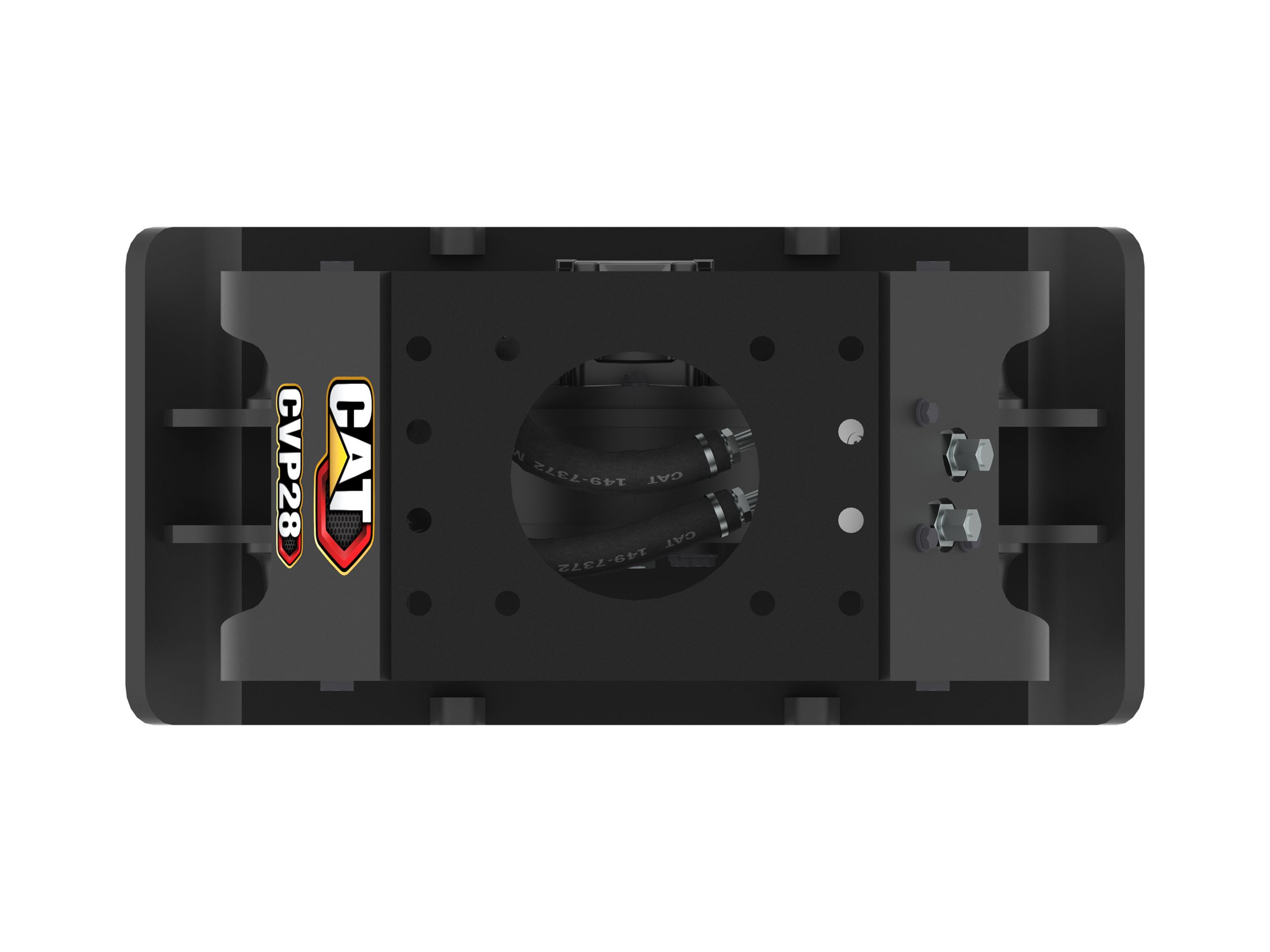

Protected Hydraulics

Hydraulic hoses are protected inside the frame of the compactor. Jumper lines are routed out the back of the compactor. Hoses are out of the way – even in tight trenches.

-

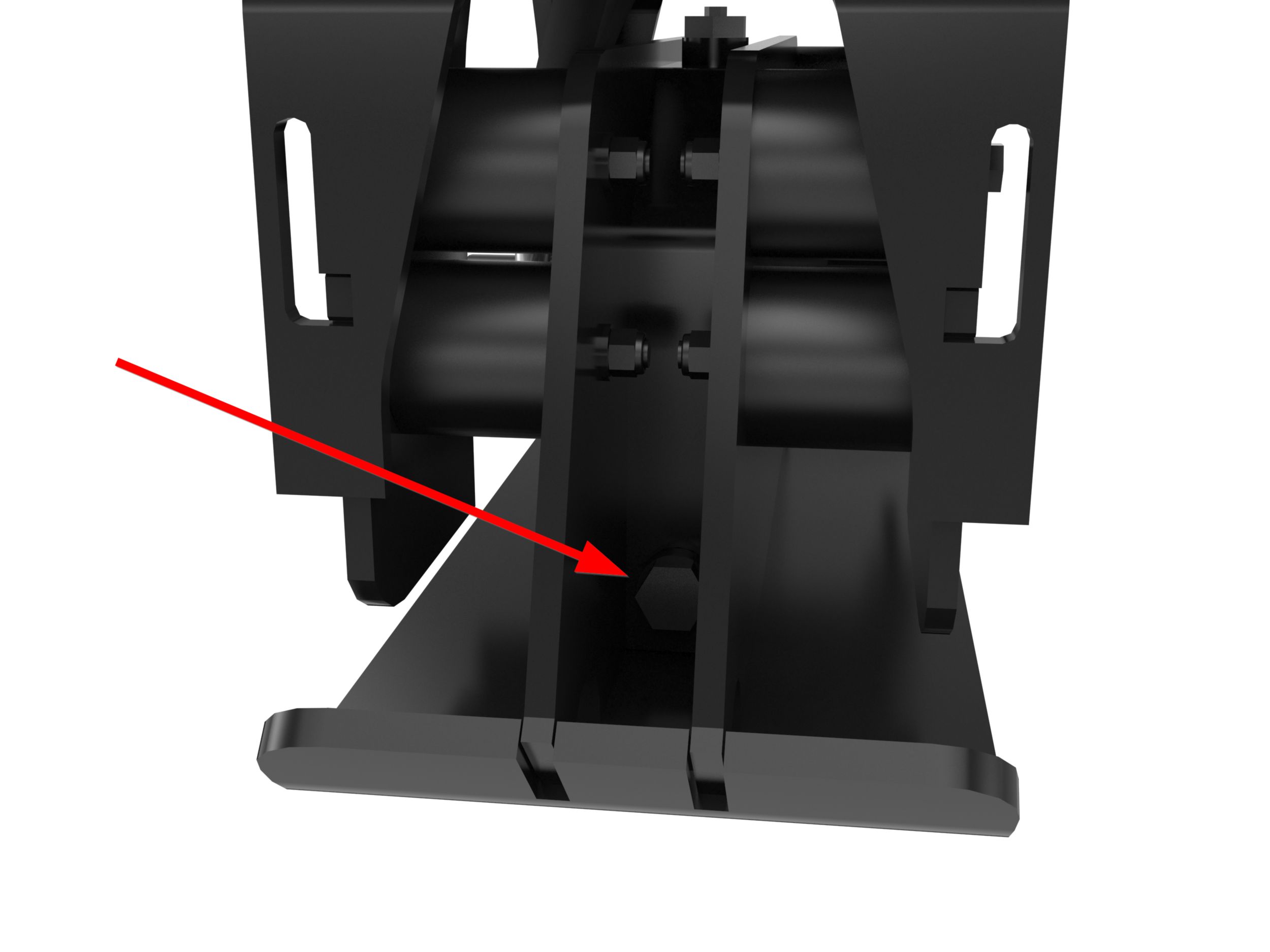

Easy Maintenance

Oil changes are simplified with the rear centerline plug. Oil can be changed while the compactor is installed.

-

Rubber Isolators

A heavy-duty steel frame and solid rubber isolator bushings deliver the maximum amount of power to the ground while minimizing machine impact.

-

Optional Backfill Blade

An optional bolt-on backfill blade can be mounted on both front and back of the compactor.

-

Optional Post/Plate Driver

Bolt-on post/plate driver allows the CVP28 to handle driving posts or plates into soil. Both are adjustable for different sizes of material as well.

Specifications

Units for specifications

General

| Impulse Force | 6294.65 lb 28 kN |

|---|---|

| Impact Frequency | 2200 bpm |

| Base Plate Width | 17.7 in 450 mm |

| Compaction Area | 3.4 ft² 0.32 m² |

| Base Plate Pressure | 12.7 psi 87.6 kPa |

| Base Plate Length | 36.2 in 920 mm |

| Optimal Hydraulic Flow | 53-68 lpm (14-18 gpm) |

| Minimum Operating Pressure | 13000-17000 kPa (1900-2500 psi) |

| Weight | 573.2 lb 260 kg |

Videos

-

Cat® Vibratory Plate Compactors at Work -

Cat® Vibratory Plate Compactors Overview